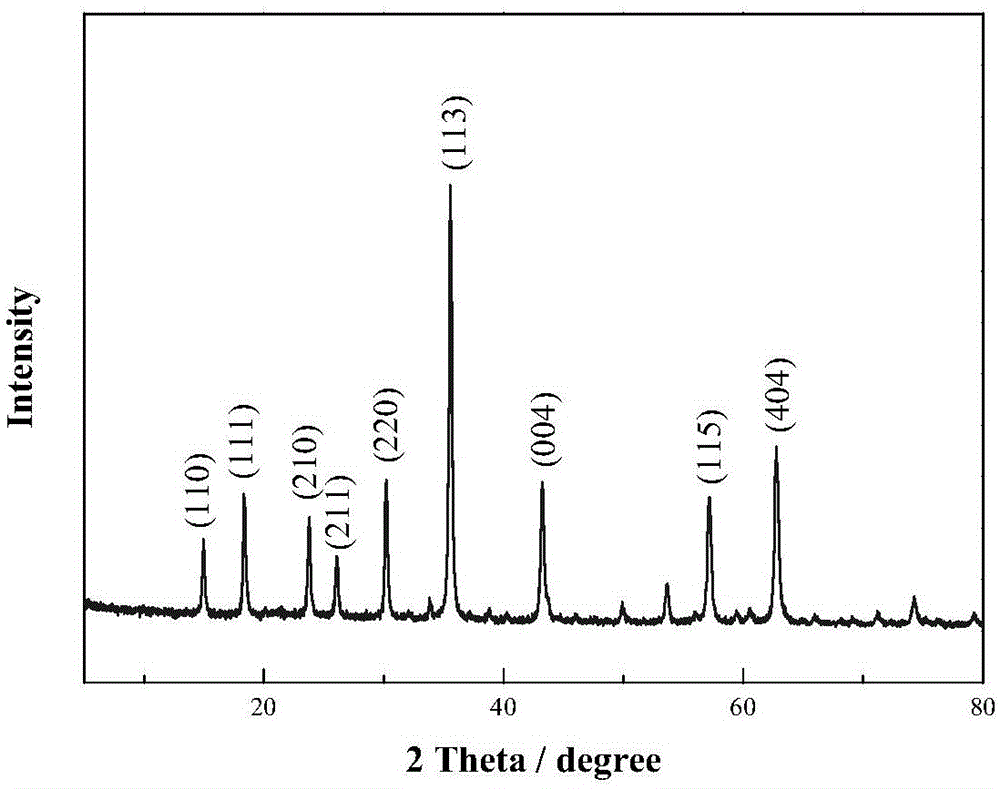

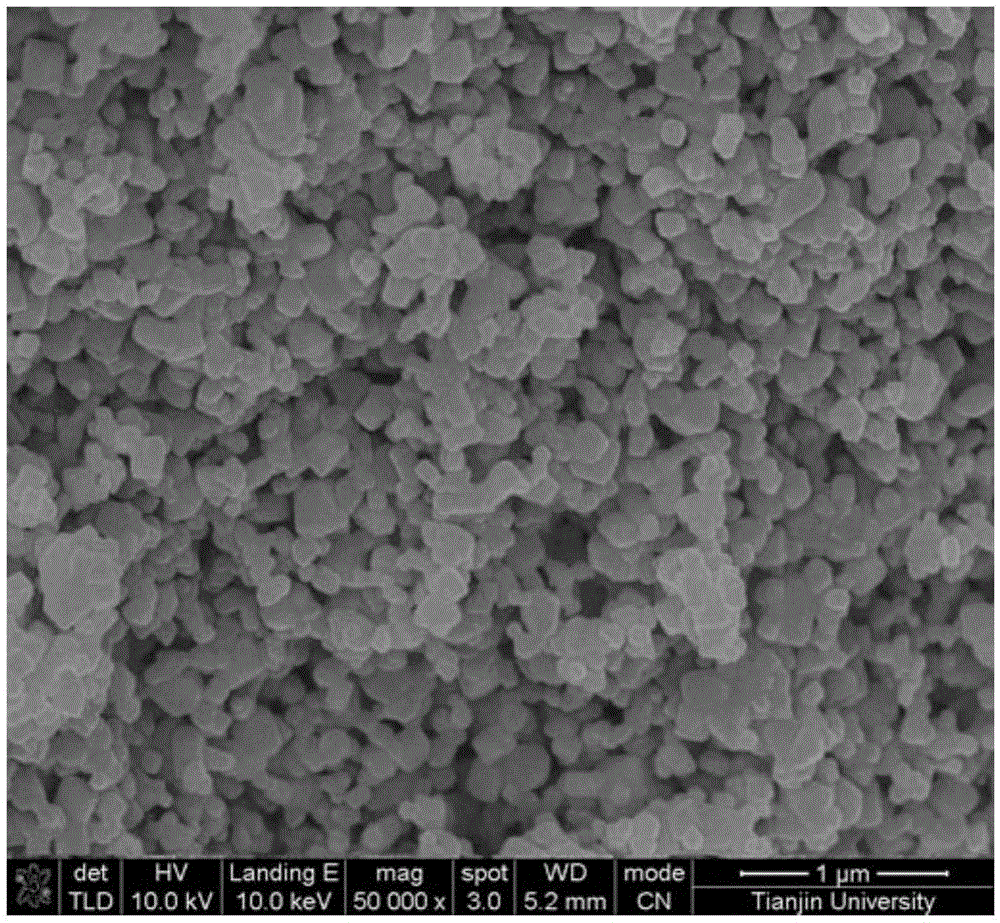

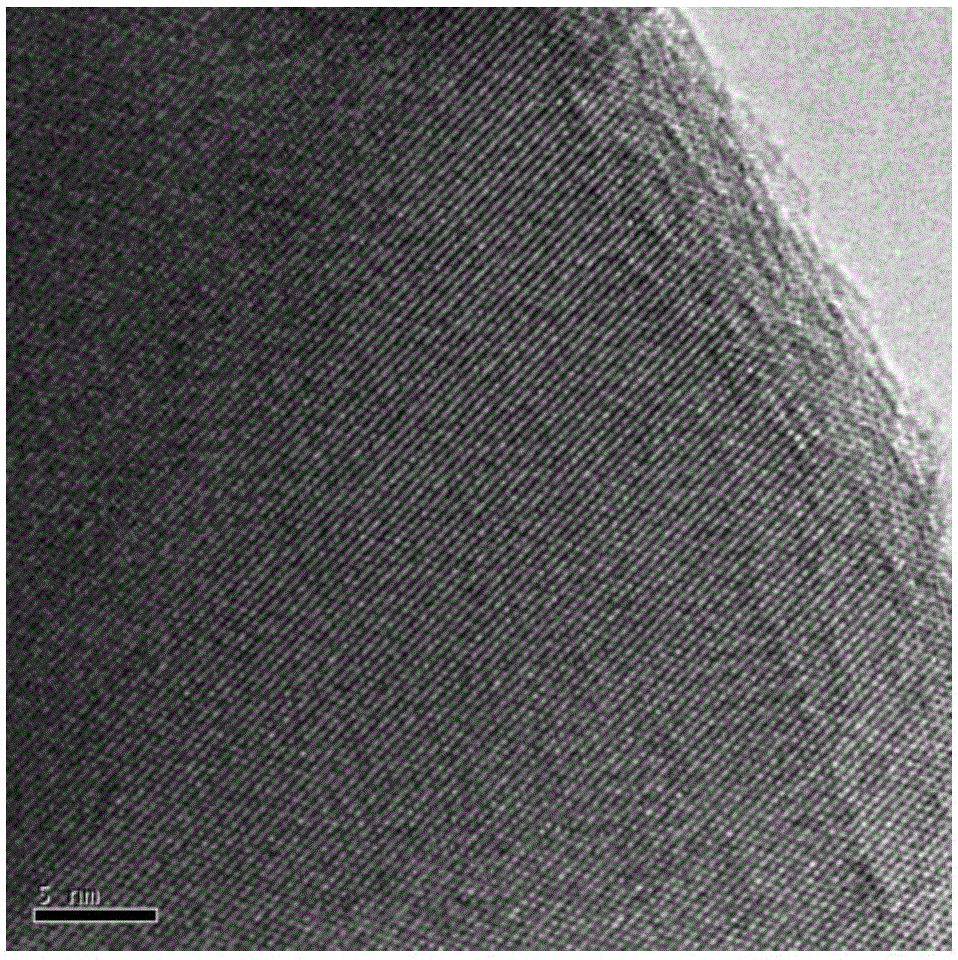

Preparation method for lithium ion battery anode active material Li2ZnTi3O8

A negative electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high cost and complicated preparation steps, and achieve the effect of reducing agglomeration and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Weigh 1.8568g of analytically pure zinc acetate, dissolve it in 50mL of organic solvent absolute ethanol, stir to make it fully dissolve to form a transparent liquid, called solution A; then add 5.3586g of analytically pure citric acid solid to solution A to form White flocculent precipitate, magnetically stirred for 0.5-1h, the molar ratio of citric acid to the total cations in the solution is controlled between: citric acid / total cations=1.0-1.5, this liquid phase mixture is called B; Add 0.6281g of analytically pure lithium carbonate, stir for 0.5-1h, then add 8.6792g of analytically pure tetrabutyl titanate liquid dropwise, and magnetically stir for 1-2h to obtain a light yellow transparent liquid mixture, called solution C, continue stirring 0.5-1h; then transfer the solution C to an 80°C constant temperature oil bath with magnetic stirring until it forms a wet gel, bake it in an 80°C forced air drying oven for 24h to make it fully dry, and then grind it in an agate ...

Embodiment 2

[0032] Weigh 1.8568g of analytically pure zinc acetate, dissolve it in 50mL of organic solvent absolute ethanol, stir to make it fully dissolve to form a transparent liquid, called solution A; then add 5.3586g of analytically pure citric acid solid to solution A to form White flocculent precipitate, magnetically stirred for 0.5-1h, the molar ratio of citric acid to the total cations in the solution is controlled between: citric acid / total cations=1.0-1.5, this liquid phase mixture is called B; Add 0.6281g of analytically pure lithium carbonate, stir for 0.5-1h, then add 8.6792g of analytically pure tetrabutyl titanate liquid dropwise, and magnetically stir for 1-2h to obtain a light yellow transparent liquid mixture, called solution C, continue stirring 0.5-1h; then transfer the solution C to an 80°C constant temperature oil bath with magnetic stirring until it forms a wet gel, bake it in an 80°C forced air drying oven for 24h to make it fully dry, and then grind it in an agate...

Embodiment 3

[0034] Weigh 1.8568g of analytically pure zinc acetate, dissolve it in 50mL of organic solvent absolute ethanol, stir to make it fully dissolve to form a transparent liquid, called solution A; then add 5.3586g of analytically pure citric acid solid to solution A to form White flocculent precipitate, magnetically stirred for 0.5-1h, the molar ratio of citric acid to the total cations in the solution is controlled between: citric acid / total cations=1.0-1.5, this liquid phase mixture is called B; Add 0.6281g of analytically pure lithium carbonate, stir for 0.5-1h, then add 8.6792g of analytically pure tetrabutyl titanate liquid dropwise, and magnetically stir for 1-2h to obtain a light yellow transparent liquid mixture, called solution C, continue stirring 0.5-1h; then transfer the solution C to an 80°C constant temperature oil bath with magnetic stirring until it forms a wet gel, bake it in an 80°C forced air drying oven for 24h to make it fully dry, and then grind it in an agate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com