Secondary curing producing method for piglet feed

A production method and secondary curing technology are applied in the field of secondary curing production of piglet feed, which can solve the problems of reducing the activity of amino acids and beneficial bacteria, reducing the nutritional value of protein, and losing the nutrition of pig feed, so as to reduce the cost of raising pigs. Effects of stress, increased survival rate, good conditioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

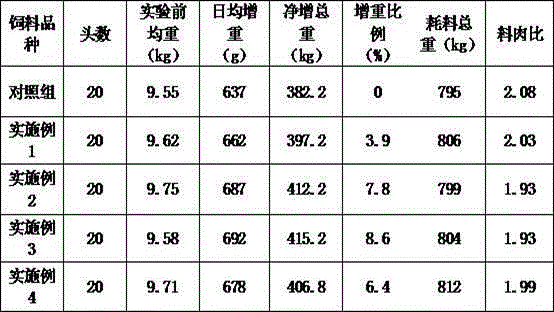

Examples

Embodiment 1

[0038] (1) The parts by weight of piglet feed ingredients are:

[0039] 20 parts of corn flour, 10 parts of wheat bran, 10 parts of bean straw, 10 parts of feather meal, 5 parts of brewer's grains, 5 parts of molasses, 1 part of red, 1 part of pulsatilla, 1 part of astragalus, 0.1 part of sea salt, 0.1 part of beneficial bacteria , 0.1 part of trace elements; the beneficial bacteria are Lactobacillus and Bacillus subtilis.

[0040] Its production method comprises the following steps:

[0041] (1) Dry a little red, pulsatilla and astragalus with a drier until the water content is less than 10%, then pulverize them with a feed mill, mix the pulverized a little red, pulsatilla and astragalus according to the above parts by weight, and pour them into In the extraction tank, add water 5-10 times the total weight of the drug, heat to 100°C and cook for 1-2 hours, when the temperature of the liquid medicine drops to 30°C-60°C, filter through a 120-mesh sieve, concentrate the filtrat...

Embodiment 2

[0045] (1) The parts by weight of piglet feed ingredients are:

[0046] 25 parts of corn flour, 12 parts of wheat bran, 12 parts of bean straw, 12 parts of feather meal, 6 parts of brewer's grains, 6 parts of molasses, 2 parts of a little red, 2 parts of pulsatilla, 2 parts of astragalus, 0.1-0.3 parts of sea salt, beneficial bacteria 0.2 parts, 0.2 parts of trace elements; the beneficial bacteria are Lactobacillus, Bacillus subtilis and Bifidobacterium.

[0047] Its production method is the same as in Example 1.

Embodiment 3

[0049] (1) The parts by weight of piglet feed materials are: 28 parts of corn flour, 14 parts of wheat bran, 14 parts of bean straw, 14 parts of feather meal, 8 parts of brewer's grains, 8 parts of molasses, 2 parts of a little red, 2 parts of Pulsatilla , 2 parts of astragalus, 0.2 part of sea salt, 0.2 part of beneficial bacteria, and 0.2 part of trace elements; the beneficial bacteria are Lactobacillus and Bifidobacterium.

[0050] Its production method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com