Rice cadmium removing machine and technology

A rice and cadmium removal technology, applied in the fields of application, food preparation, climate change adaptation, etc., can solve the problems of unfavorable rice utilization and processing, lack of pre-treatment and lack of post-treatment of rice, etc., and achieve good social and economic effects , Conducive to subsequent processing, the effect of expanding the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

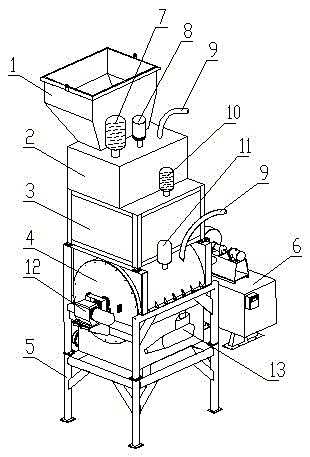

[0032] A rice cadmium removal machine comprises a frame 5, a feed hopper 1, a salt leaching chamber 2, a fermentation cadmium removal chamber 3, an acid bubble cadmium discharge chamber 4, a drying chamber 6, and a rotary discharge hopper.

[0033] The frame 5 is welded by angle steel, and the frame 5 is installed with a feed hopper 1, a salt immersion chamber 2, a fermentation decadmium chamber 3, and an acid bubble cadmium discharge chamber 4 from top to bottom. The method is conducive to the downward movement of rice and solution under the action of gravity, which is in line with the whole process flow. Feeding hopper 1, salt immersion chamber 2, fermentation decadmium removal chamber 3, and acid bubble cadmium discharge chamber 4 are connected to each other through a movable sealing plate (not shown in the figure), and the movable sealing plate can be driven by a motor. Plate, hydraulic or pneumatically controlled movable sealing plate can also be used. A water outlet wit...

Embodiment 2

[0044] Adopt a kind of rice removing cadmium machine identical with embodiment 1, and carry out rice removing cadmium according to the following steps:

[0045] (1) Take 25 kg of rice with cadmium exceeding the standard and put it into the feeding hopper 1.

[0046] (2) Salt immersion treatment: open the movable sealing plate, so that the rice in the feed hopper 1 enters the salt immersion chamber 2, and at the same time open the salt box 7 and the water inlet pipe 9 above the salt immersion chamber 2, and add 380g of salt and 27.5kg Clear water, preferably distilled water, and start the vertical mixer 8 to stir, and the salt soaking time is 2h.

[0047] (3) Fermentation cadmium removal: open the movable sealing plate between the salt immersion chamber 2 and the fermentation cadmium removal chamber 3, the rice soaked in salt water and the soaking liquid enter the fermentation decadmium chamber 3, and then open the edible fungi box 10, Add 100 g of Lactobacillus (Lactobacillus...

Embodiment 3

[0052] Adopt a kind of rice removing cadmium machine identical with embodiment 1, and carry out rice removing cadmium according to the following steps:

[0053] (1) Put 30 kg of cadmium-exceeding rice into the feeding hopper 1.

[0054] (2) Salt immersion treatment: open the movable sealing plate, so that the rice in the feed hopper 1 enters the salt immersion chamber 2, and at the same time open the salt box 7 and the water inlet pipe 9 above the salt immersion chamber 2, and add 300g of salt and 33kg of water , the preferred distilled water of the clear water, and start the vertical mixer 8 to stir, and the salt soaking time is 2h.

[0055] (3) Fermentation cadmium removal: open the movable sealing plate between the salt immersion chamber 2 and the fermentation cadmium removal chamber 3, the rice soaked in salt water and the soaking liquid enter the fermentation decadmium chamber 3, and then open the edible fungi box 10, Add 120 g of Lactobacillus plantarum, 30 g of Strepto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com