Forming process of hook part bottom hole of pressurized water reactor control rod drive mechanism

A technology of driving mechanism and forming process, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems that the quality of parts cannot be effectively traced, and on-site supervision is not allowed, and achieve high surface strength, control strength, and easy stacking The effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

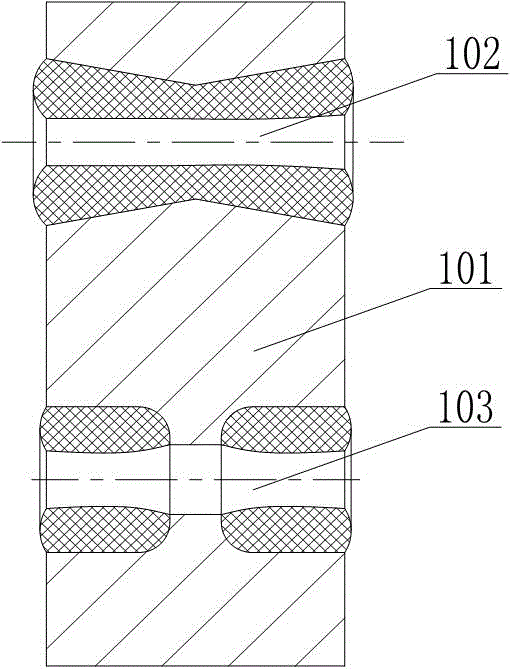

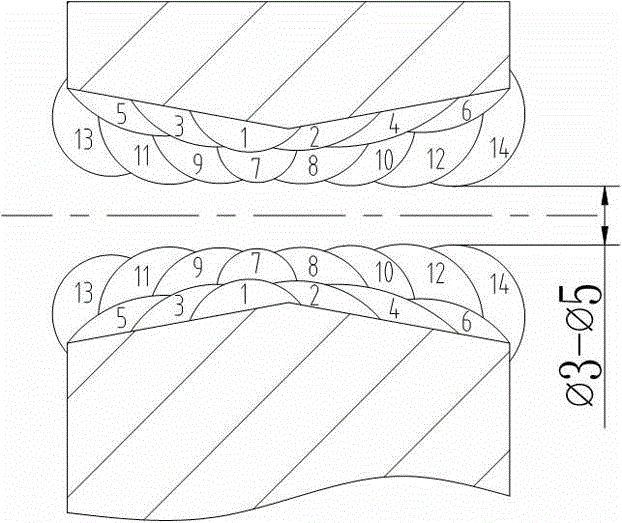

[0023] like Figures 3 to 4 As shown, a forming process of the bottom hole of the claw part of the PWR control rod drive mechanism of the present invention includes the surfacing step of the tapered hole and the surfacing step of the stepped hole:

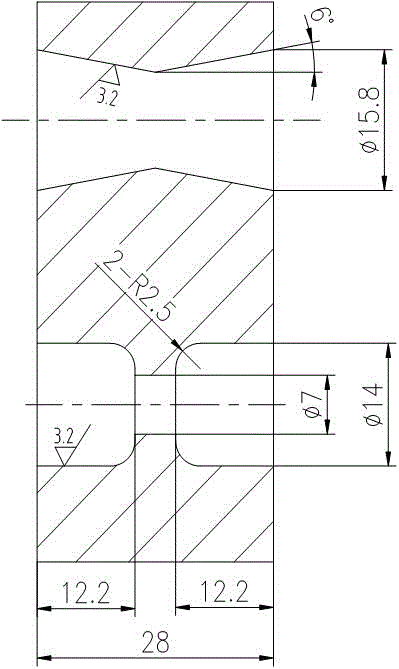

[0024] aFirst of all, the material is prepared. The base material of the claw 101 is made of 00Cr18Ni10N austenitic stainless steel. The welding material is Stellite-6. The chemical composition of the welding wire meets the requirements of the corresponding standards. The specification is φ2.7mm. figure 2 the size and shape of;

[0025] b Welding torch, gas and pressure reducing valve flowmeters are all connected as required, ignite and adjust the flame to the requirement, the flame type is carbonization flame, the ratio is 1:2-2.5;

[0026] c The hook and claw parts are ready and preheated according to the process. After preheating, surfacing welding is carried out alternately from both sides on the special rotary tooling. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com