Method for preparing graphene nano-belt through sealed oxidation

A graphene nanobelt, oxidation method, applied in nanotechnology, pressure vessels used in chemical processes, pressure vessels/vacuum vessels, etc., can solve the problems of less product structural defects, time-consuming and energy-consuming, cumbersome steps, etc. Good shape, shortened reaction time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

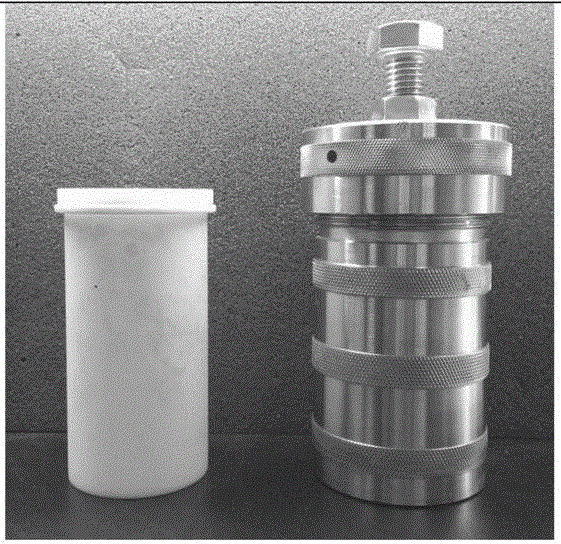

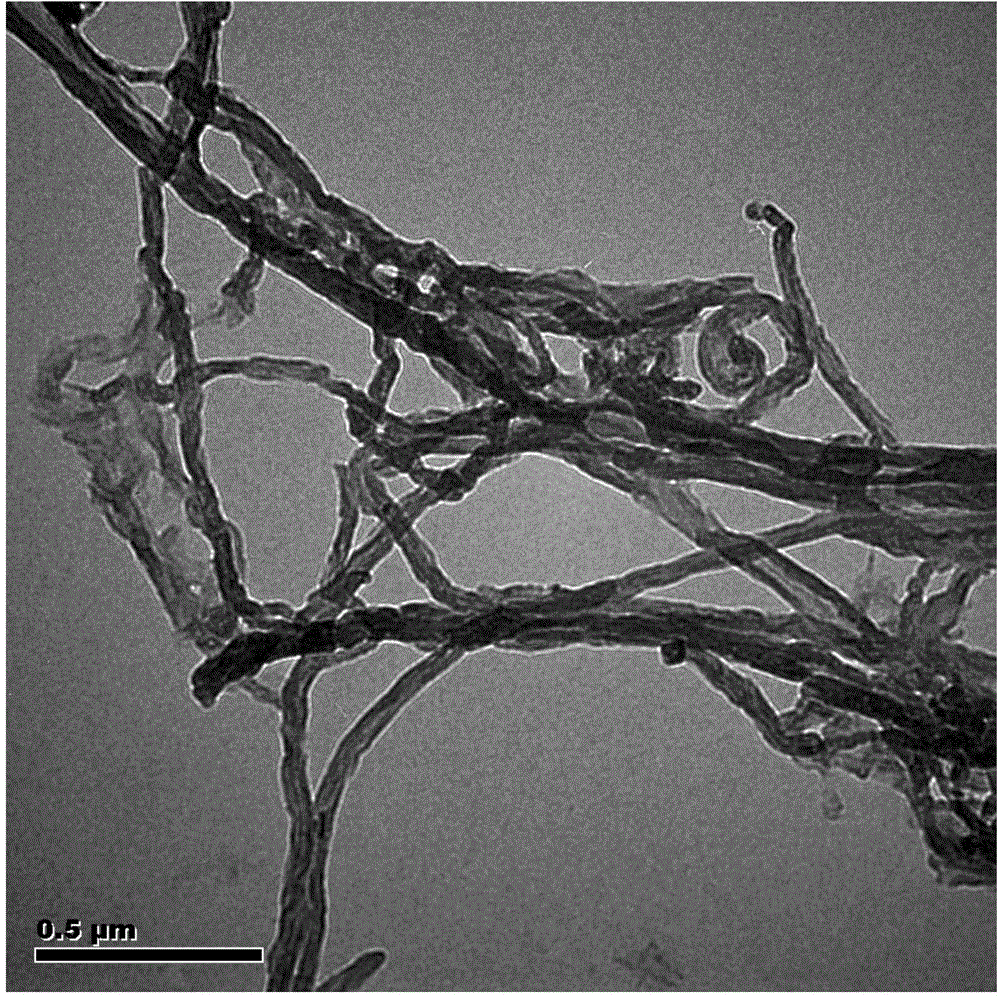

[0032] Take 375mg of potassium permanganate, 75mg of multi-walled carbon nanotubes (OD>50nm), and 75mL of 98% sulfuric acid into a 100mL polytetrafluoroethylene-lined reactor in turn, shake to make the dispersion even, seal it, and heat it to 70°C for 3 hours at a constant temperature; Cool to room temperature, add ice cubes (200mL deionized water to freeze), add 5mL of 30% hydrogen peroxide while stirring, wash with 1 liter of 1M hydrochloric acid, and finally filter and wash with deionized water until neutral; ultrasonic 20min, natural at room temperature After drying, 90.5 mg of graphene nanoribbons were obtained with a yield of 120.67%.

[0033] figure 1 It is a TEM image of the graphene nanobelt prepared in Example 1 of the present invention. from figure 1 It can be seen that graphene nanoribbons have been successfully prepared, and the prepared graphene nanoribbons have uniform morphology. The graphene nanoribbons prepared in this example have a width of 80-90nm and a...

Embodiment 2

[0035] Take 375mg of potassium permanganate, 75mg of multi-walled carbon nanotubes (OD>50nm), and 75mL of 98% sulfuric acid into a 100mL polytetrafluoroethylene-lined reactor in turn, shake to make the dispersion even, airtight, and heat to 60°C for 3 hours. Cool to room temperature, add ice cubes (200mL deionized water to freeze), add 5mL of 30% hydrogen peroxide while stirring, filter and wash with deionized water until neutral, and dry naturally at room temperature to obtain graphene nanobelts.

[0036] figure 2 It is a TEM image of the graphene nanobelt prepared in Example 2 of the present invention. The graphene nanobelts made in this example have a bandwidth of 70-80nm and a length>1um.

Embodiment 3

[0038] Take 375mg of potassium permanganate, 75mg of multi-walled carbon nanotubes (OD>50nm), and 75mL of 98% sulfuric acid into a 100mL polytetrafluoroethylene-lined reactor in turn, shake to make the dispersion even, airtight, and heat to 60°C for 3 hours; cool To room temperature, add ice cubes (200mL deionized water to freeze), add 5mL of 30% hydrogen peroxide while stirring, filter and wash with deionized water until neutral; ultrasonic for 40min, and dry naturally at room temperature to obtain graphene nanobelts.

[0039] image 3 It is a TEM image of the graphene nanobelt prepared in Example 3 of the present invention. The graphene nanoribbon prepared in this example is 70-80nm, and the length is <1um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com