Nixing pottery dedicated matt light brown raw glaze and preparation method thereof

A technology of Nixing pottery and raw material, applied to a glaze of Nixing pottery and its preparation field, can solve the problems of contradicting product concept, covering surface effect, low firing temperature, etc., and achieving easy large-scale production and preparation Simple method and easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

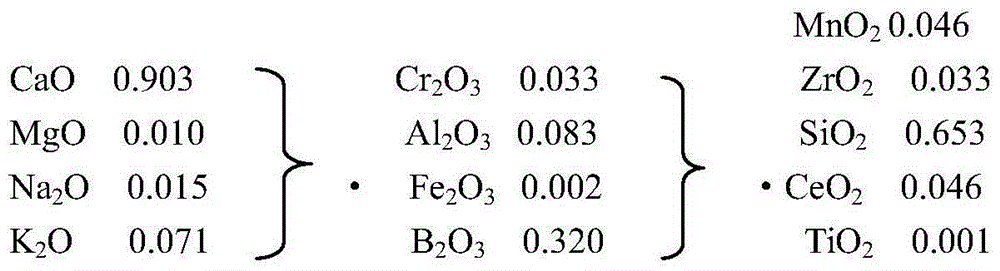

[0022] The preparation method of the matte light brown raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0023] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 6.8 parts of zirconium silicate, 7.8 parts of cerium oxide, 20 parts of feldspar, 8 parts of quartz, 14 parts of calcite, 9 parts of verosite, 3 parts of chromium oxide, 3 parts of manganese dioxide, 5.5 parts of talc, and 8 parts of calcium borate are uniformly mixed to form a mixed solid raw material;

[0024] Step 2, according to the ratio of mixed solid ball stone: raw material: water = 2:1:0.8, add ball mill to mix ball mill respectively, and the time of mixing ball mill is 6h / kg to form slurry;

[0025] Step 3, detecting the fineness of the slurry;

[0026] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0027] Step five, age the...

Embodiment 2

[0031] The preparation method of the matte light brown raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0032] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 7.2 parts of zirconium silicate, 8.3 parts of cerium oxide, 26 parts of feldspar, 12 parts of quartz, 17 parts of calcite, 12 parts of verosite, 6 parts of chromium oxide, 6 parts of manganese dioxide, 7.6 parts of talc, and 10.6 parts of calcium borate are uniformly mixed to form a mixed solid raw material;

[0033] Step 2, according to the ratio of mixed solid ball stone: raw material: water = 2: 1: 0.8, respectively add ball mill to mix ball mill, and the time of mixing ball mill is 8h / kg to form slurry;

[0034] Step 3, detecting the fineness of the slurry;

[0035] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0036] Step five, ...

Embodiment 3

[0040] The preparation method of the matte light brown raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0041] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 7 parts of zirconium silicate, 8 parts of cerium oxide, 25 parts of feldspar, 10 parts of quartz, 15 parts of calcite, 10 parts of verosite, 5 parts of chromium oxide, 4 parts of manganese dioxide, 6 parts of talc, and 10 parts of calcium borate are uniformly mixed to form a mixed solid raw material;

[0042] Step 2, according to the ratio of mixing solid ball stone: raw material: water = 2:1:0.8, add the ball mill to mix ball milling, and the time of mixing ball milling is 7h / kg to form a slurry;

[0043] Step 3, detecting the fineness of the slurry;

[0044] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0045] Step five, age the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com