Metal-organic frameworks based on cu(i) and their preparation methods and applications

A metal-organic framework and organic ligand technology, applied in the direction of 1/11 organic compounds without C-metal bonds, organic chemistry, copper organic compounds, etc., to achieve high selectivity, ensure accuracy, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Preparation of organic ligand L

[0061] To 3.48g of 2,4,6-triethyl-1,3,5-trimellitic acid chloride, 4.41g of 5-(3-pyridyl)tetrazole and 10ml of anhydrous pyridine were added to react at 120°C for 2h. After the system was cooled, 100 ml of water was added, and the dark crude product was obtained by suction filtration, dried, and column chromatography (ethyl acetate) to obtain 3.1 g of light yellow powder, with a yield of 53%. We passed 1 H NMR and IR characterize the compound, and the results are shown in Figure 4 with Figure 5 . 2,4,6-Triethyl-1,3,5-trimellitic acid chloride References C.-W.Zhao,J.-P.Ma,Q.-K.Liu,Y.Yu,P.Wang ,Y.-A.Li,K.Wang and Y.-B.Dong,Green Chem.,2013,15,3150-3154.

[0062]

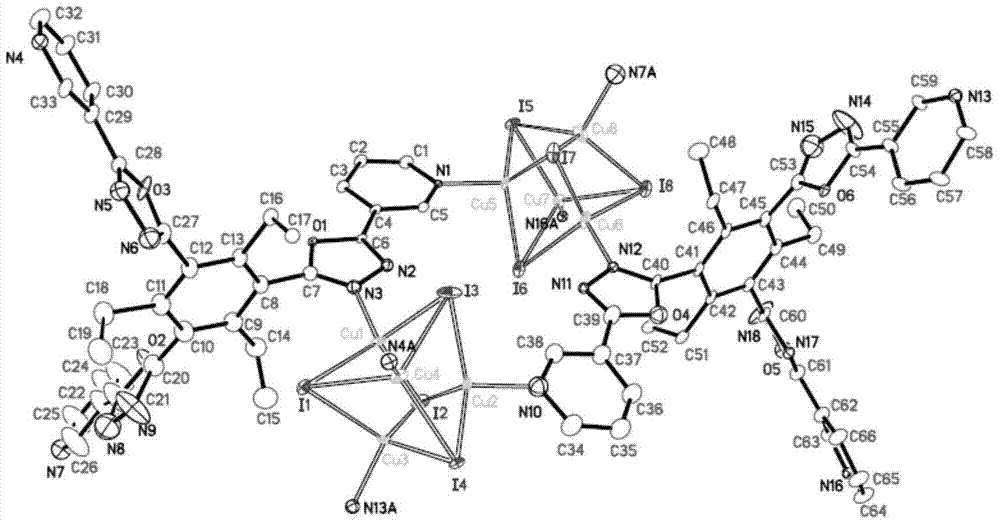

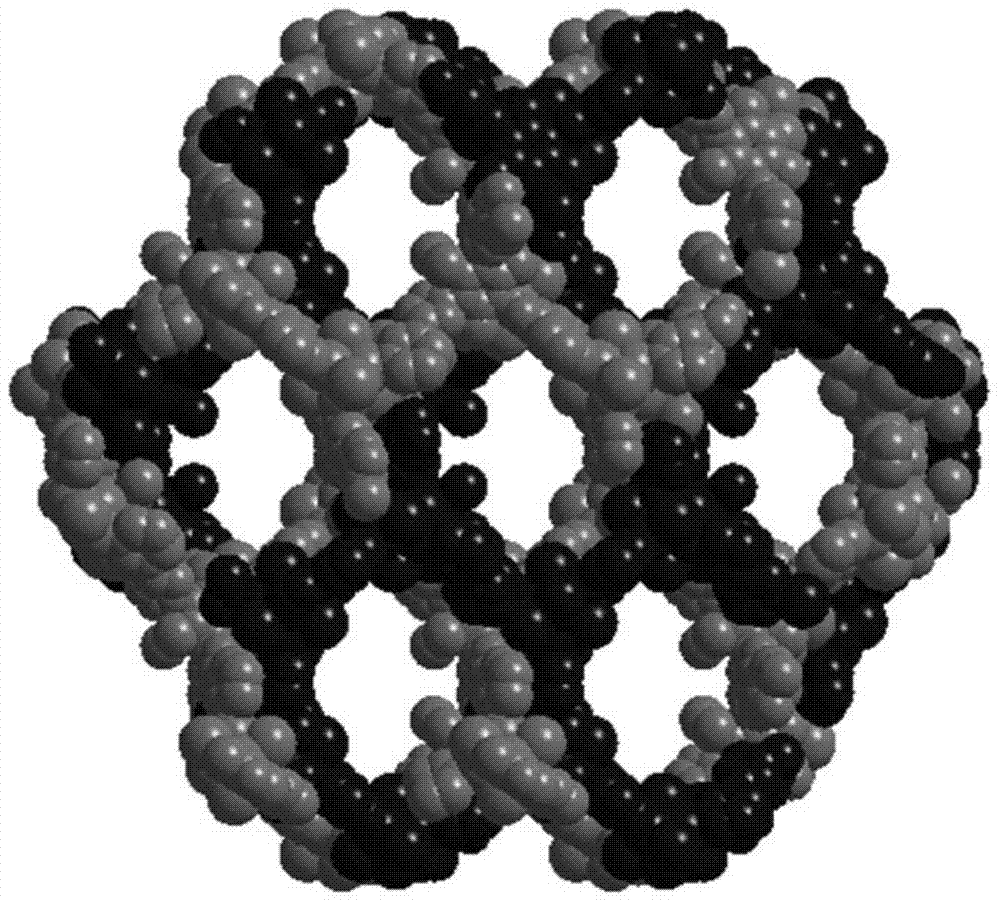

[0063] 2. Synthesis of CuI-MOF

[0064] 30 mg of organic ligand L and 40 mg of CuI were respectively dissolved in 10 mL of acetonitrile, the two were mixed uniformly, and allowed to stand at 10°C for 15 hours to obtain 53 mg of metal organic framework CuI-MOF, with a yield of 7...

Embodiment 2

[0082] 1. Preparation of organic ligand L

[0083] Add 3.88 g of 5-(3-pyridyl)tetrazole and 9.5 mL of anhydrous pyridine to 2.80 g of 2,4,6-triethyl-1,3,5- trimesoyl chloride, and react at 110°C for 3.5 h. After the system was cooled, 100 mL of water was added, the dark crude product was obtained by suction filtration, dried, and column chromatography (ethyl acetate) was used to obtain 3.0 g of light yellow powder, with a yield of 52%.

[0084] 2. Synthesis of CuI-MOF

[0085] Dissolve 27 mg of organic ligand L and 30 mg of CuI in 9 mL of acetonitrile respectively, mix the two uniformly, and stand at 30°C for 12 hours to obtain 51 mg of metal organic framework CuI-MOF, with a yield of 76% (based on L).

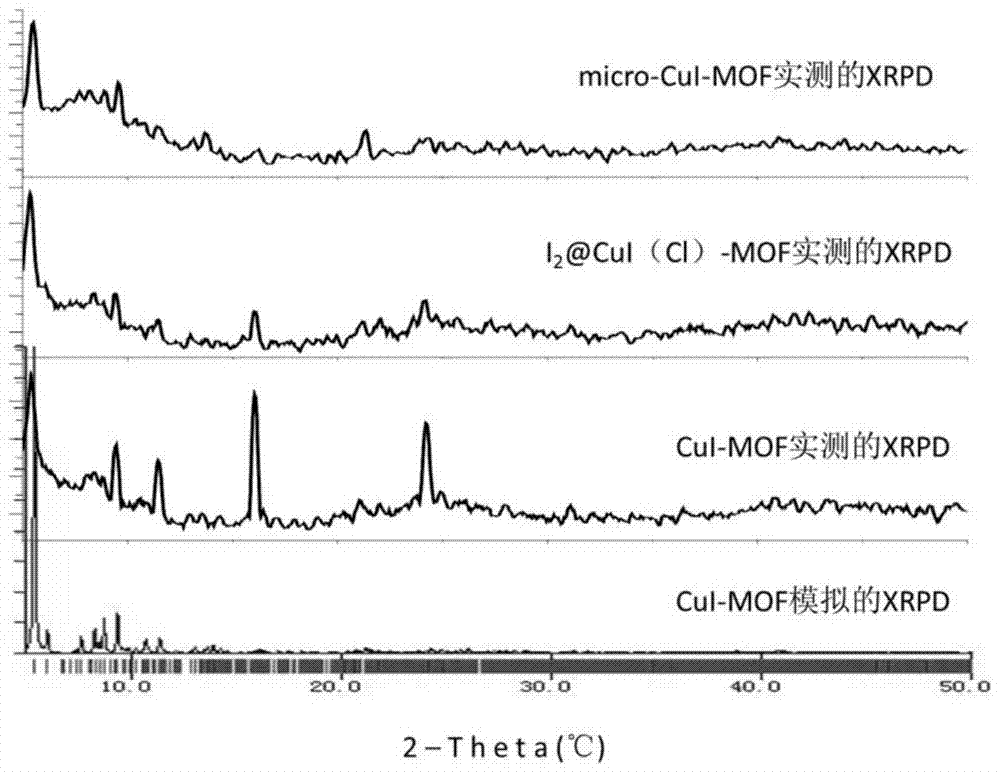

[0086] 3. I 2 Synthesis of @CuI(Cl)-MOF

[0087] The CuI-MOF crystals prepared in Example 2 were placed in a 50 mL container with a concentration of HCl (g) of 200 ppm at 25°C, taken out for 14 minutes, and allowed to stand in the air for 150 minutes to obtain I 2 @CuI(Cl)-MOF.

[0088]...

Embodiment 3

[0091] 1. Preparation of organic ligand L

[0092] To 3.80g of 2,4,6-triethyl-1,3,5-trimellitic acid chloride was added 5.51g of 5-(3-pyridyl)tetrazole, 11mL of anhydrous pyridine, and reacted at 130°C for 1.5h. After the system was cooled, 100 mL of water was added, and the dark crude product was obtained by suction filtration, dried, and column chromatography (ethyl acetate) to obtain 3.2 g of pale yellow powder, with a yield of 55%.

[0093] 2. Synthesis of CuI-MOF

[0094] 35 mg of organic ligand L and 42 mg of CuI were respectively dissolved in 12 mL of acetonitrile, and the two were mixed uniformly, and allowed to stand for 15 hours at 10° C. to obtain 55 mg of metal organic framework CuI-MOF with a yield of 78% (based on L).

[0095] 3. I 2 Synthesis of @CuI(Cl)-MOF

[0096] The CuI-MOF crystal prepared in Example 2 was placed in a 50 mL container with a HCl (g) concentration of 150 ppm at 25° C., taken out for 10 minutes, and allowed to stand in the air for 100 minutes to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com