Ionized backbone polymer capable of removing particulate pollution and preparation method thereof

An ionization, polymer material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as inability to cope with extremely small pollutants, high cost of use, waste of energy, etc., to achieve harmonious coexistence and curb costs. , the effect of problem simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

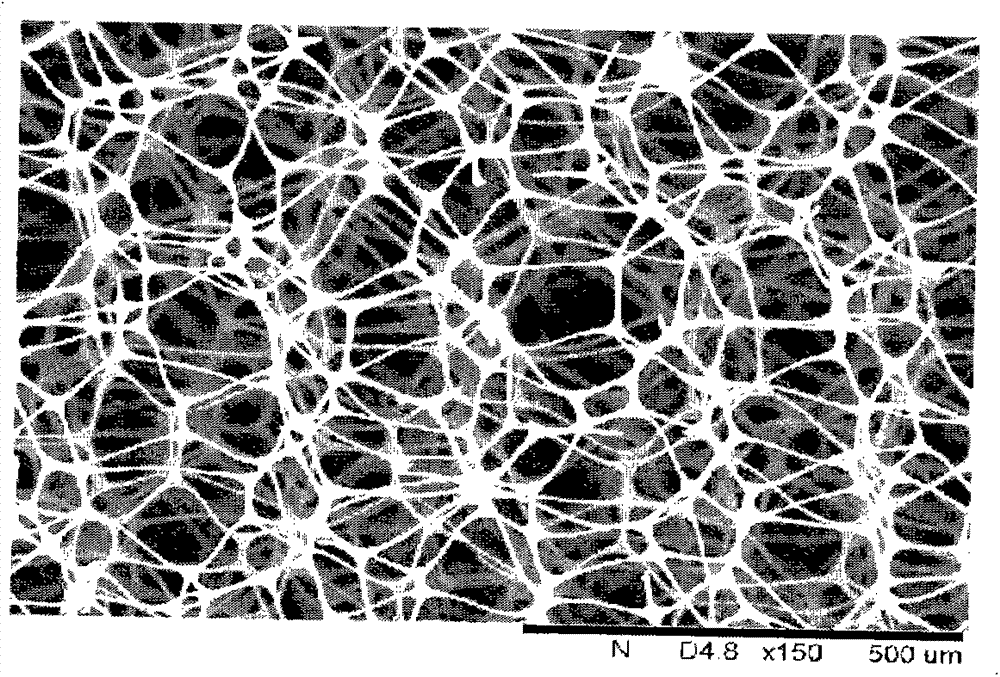

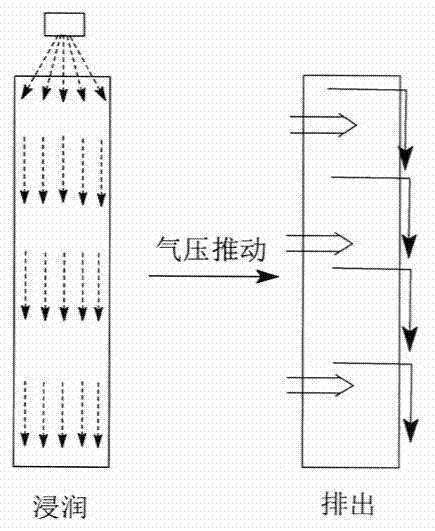

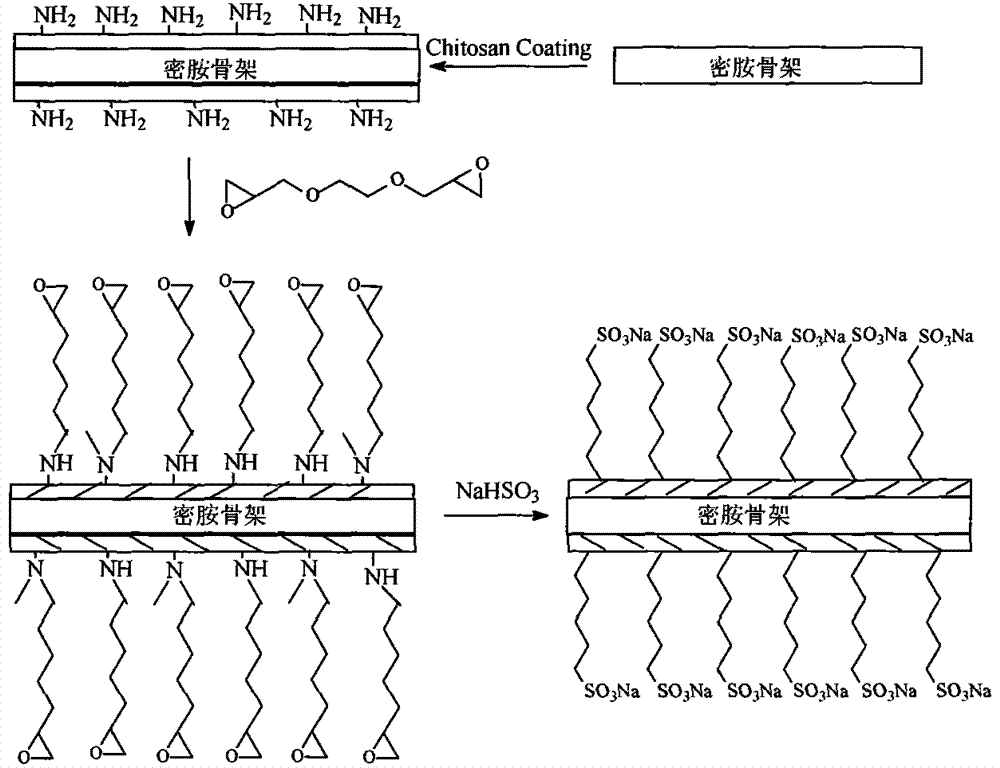

[0020] Material preparation: first, dissolve commercial chitosan in dilute acetic acid aqueous solution (concentration of 1-2wt.% for viscosity greater than 400mpa; concentration of 2-3wt.% for viscosity in the range of 200-400mpa) and add A small amount of cationic surfactant (such as dodecyltrimethylammonium chloride, the content in the solution is 0.1 ~ 0.2wt. %), then, commercially available melamine sponge (melamine and formaldehyde cross-linking reaction made foam material, now commercialized) soaked in the solution, after taking it out, suck off the excess solution with a vacuum to ensure that there is no solution flowing out under standing, dry it in an oven at 60°C for 2 to 3 hours, soak it in Treat in sodium carbonate solution with pH = 9-10 for 20-30 minutes, after deprotonation of chitosan, an insoluble film will be formed to cover the surface of the framework, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com