A superporous cationic polymer capable of removing bacteria in the air and its preparation method

A cationic polymer and ultra-large pore technology, which is applied in the fields of alkali metal compounds, chemical instruments and methods, deodorization, etc., can solve problems such as microbial pollution, and achieve the effect of simple operation, reasonable operating cost and ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

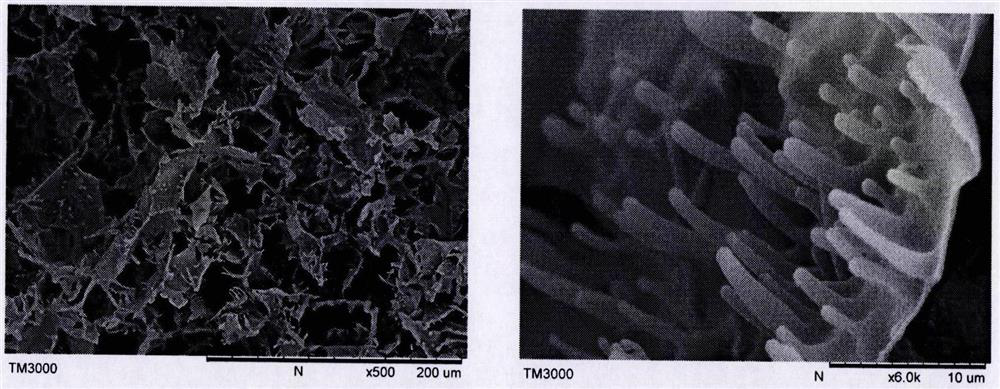

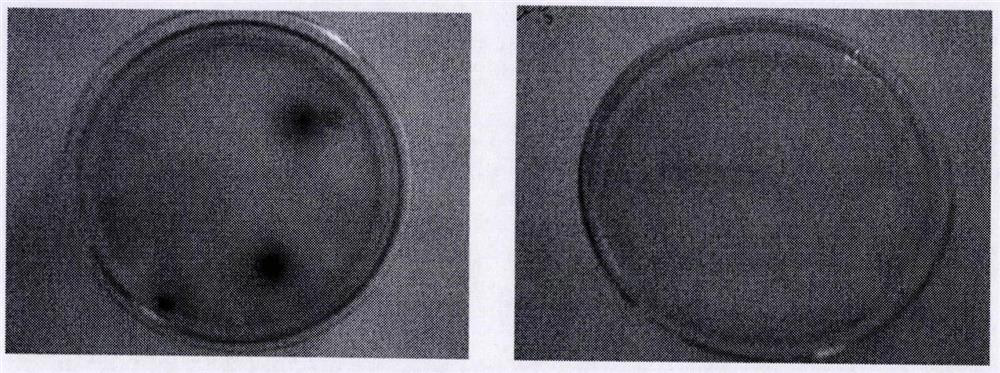

Embodiment 1

[0020] 60.0g of trimethylolpropane was heated and melted until it became a transparent and flowable liquid, and 3.0g of epoxy resin E-51 was added to stir and disperse, and 0.44g of diethylenetriamine was added, cooled with ice water and vigorously stirred to make the exotherm uniform, and viscous Thick semi-solid, which contains a large number of tiny crystals, poured into a plastic mold, after being completely solidified, placed in the refrigerator for further cooling and crystallization for 3 hours, after freezing, a hard white solid was obtained, solidified at 45°C for 12 hours, soaked in water repeatedly After the trimethylolpropane is completely removed, dry at room temperature in a vacuum to obtain a white foamy material, put the polymer material into an ethanol solution of benzyl bromide, keep the concentration of the solution at 4wt.%, soak and react at 50°C for 2 hours, and then soaked in water for 5 to 6 hours, the treated material has obvious expansion and softening...

Embodiment 2

[0022] Heat and melt 90.0g trimethylolpropane until it becomes a transparent and flowing liquid, add 3.0g epoxy resin E-51 and stir to disperse, then add 0.50g diethylenetriamine, keep stirring to obtain a good dispersion, cool with ice water and vigorously Stir to make it release heat evenly to obtain a viscous semi-solid, which contains a large number of tiny crystals, pour it into a plastic mold, and place it in the refrigerator for further cooling and crystallization for 4 hours after being completely solidified. After freezing, a hard white solid is obtained. Cure at ℃ for 14 hours, soak in water repeatedly until the trimethylolpropane is completely removed, dry in vacuum at room temperature to obtain a white foam material, put the polymer material into the ethanol solution of benzyl bromide, and keep the concentration of the solution at 2wt .%, soaked at 50°C for 3 hours, and then soaked in water for 5 to 6 hours. The treated material has obvious swelling and softening ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com