Pericarpium citri reticulatae viride extract for cigarettes and application of extract

A technology of extract and green skin, applied in the fields of application, tobacco, food science, etc., can solve the problems of poor smoking experience of low-tar cigarettes, simple utilization of green skin, etc., and achieve important market development and application prospects, low cost, and technology. Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

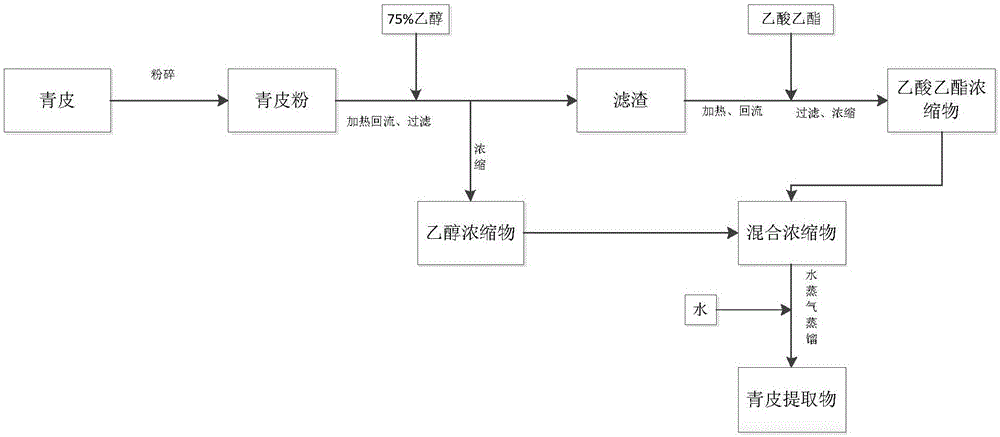

[0029] Grind 500g of sun-dried green bark through a 20-mesh sieve, add 75% ethanol according to a solid-liquid ratio of 1:5 (g:mL), heat and reflux for extraction for 5 hours, filter to obtain the filtrate and filter residue, and distill the filtrate to remove the solvent under reduced pressure , to obtain the first concentrate; filter the obtained filter residue, add ethyl acetate according to a solid-liquid ratio of 1:3 (g:mL), heat and reflux for extraction for 1 h, filter, and distill off the solvent under reduced pressure to obtain the second concentrate; combine The obtained first concentrate and second concentrate are mixed concentrates; add deionized water to the mixed concentrate according to the ratio of solid to liquid of 1:1 (g:mL), heat to collect fractions, and collect them into the mixed concentrate When the weight reached 40%, stop collecting, and obtain the extract A15g of the bark bark of tobacco.

Embodiment 2

[0031] Grind 500g of sun-dried green bark through a 40-mesh sieve, add 75% ethanol according to a solid-liquid ratio of 1:10 (g:mL), heat and reflux for extraction for 10 hours, filter to obtain the filtrate and filter residue, and distill the filtrate to remove the solvent under reduced pressure , to obtain the first concentrate; filter the obtained filter residue, add ethyl acetate according to a solid-liquid ratio of 1:5 (g:mL), heat and reflux for extraction for 4h, filter, and distill off the solvent under reduced pressure to obtain the second concentrate; combine The obtained first concentrate and second concentrate are mixed concentrates; add deionized water to the mixed concentrate according to the solid-liquid ratio of 1:3 (g:mL), heat to collect fractions, and collect them into the mixed concentrate When the weight reaches 60%, the collection is stopped, and the extract B24g of the bark bark for tobacco is obtained.

Embodiment 3

[0033] Grind 500g of sun-dried green bark through a 60-mesh sieve, add 75% ethanol according to a solid-liquid ratio of 1:7.5 (g:mL), heat and reflux for extraction for 8 hours, and filter to obtain the filtrate and filter residue, wherein the filtrate is distilled off under reduced pressure to remove the solvent , to obtain the first concentrate; filter the obtained filter residue, add ethyl acetate according to the solid-liquid ratio of 1:4 (g:mL), heat and reflux for extraction for 2h, filter, and distill off the solvent under reduced pressure to obtain the second concentrate; combine The obtained first concentrate and second concentrate are mixed concentrates; add deionized water to the mixed concentrate according to the solid-liquid ratio of 1:2 (g:mL), heat to collect fractions, and collect them into the mixed concentrate Stop collecting at 50% of the weight, and get the green bark extract C19g for tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com