A simple and quick test method for rotatability

A test method and fast technology, applied in the field of machinery, can solve the problems of little practical test reference significance of rotatability, great impact on test results, high test cost, etc., to avoid the influence factor of the pass, and to achieve high accuracy of test results , the effect of high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

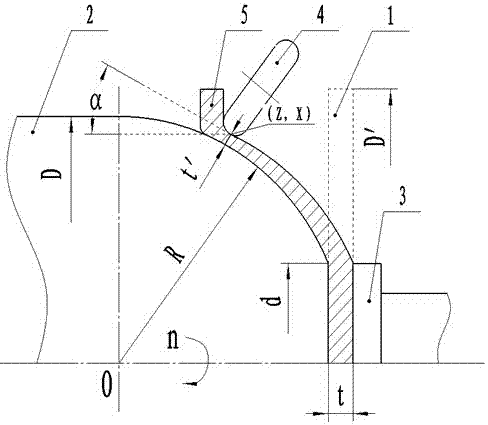

[0027] see figure 1 , this embodiment takes the spinability test of Q345B material under certain heat treatment conditions as an example,

[0028] In this embodiment, the material that needs to be tested for spinability is Q345B flat blank 1 with a wall thickness t of 26.9mm. The diameter D of the core mold 2 used in the test is φ493.2mm, and the diameter d of the plane end of the core mold 2 is φ60mm. The shape of the wheel 4 is SR type (wherein, the diameter is φ300mm, and the fillet radius is 40mm);

[0029] According to the diameter D of the mandrel 2, the blanking size is determined to be 550mm×550mm, and the blanking work is completed by using a shearing machine; the flat blank 1 is pressed and fixed on the mandrel 2 by using the tail top 3, and driven by the main shaft, The flat blank 1 will rotate together with the mandrel 2;

[0030] In the machine tool coordinate system, use a 0.05mm feeler gauge to measure the gap between the rotary wheel 4 and the mandrel 2, comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com