Material partial pressure gas-release rate test device and method

A testing device and the technology of outgassing rate, applied in the field of material partial pressure outgassing rate testing device, can solve the problems of inaccurate measurement results, complex testing process, incomparability of partial pressure outgassing rate, etc., and achieve simple experimental operation steps. , The measurement device has a simple structure and improves the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

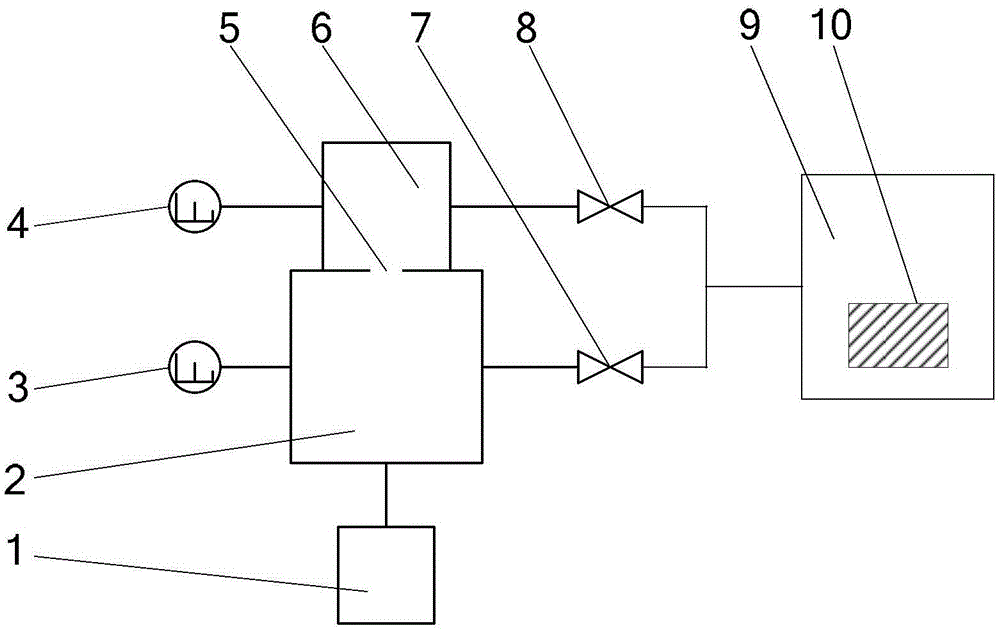

[0036] The invention provides a device and method for testing material partial pressure outgassing rate. The device comprises a measuring chamber, a vacuum pump group and a flow-limiting small hole. The vacuum pump unit is connected to the measurement chamber through a plug-in valve, the front end of the flow-limiting small hole is connected to the measurement chamber through an angle valve, and the rear end is directly connected to the vacuum pump unit.

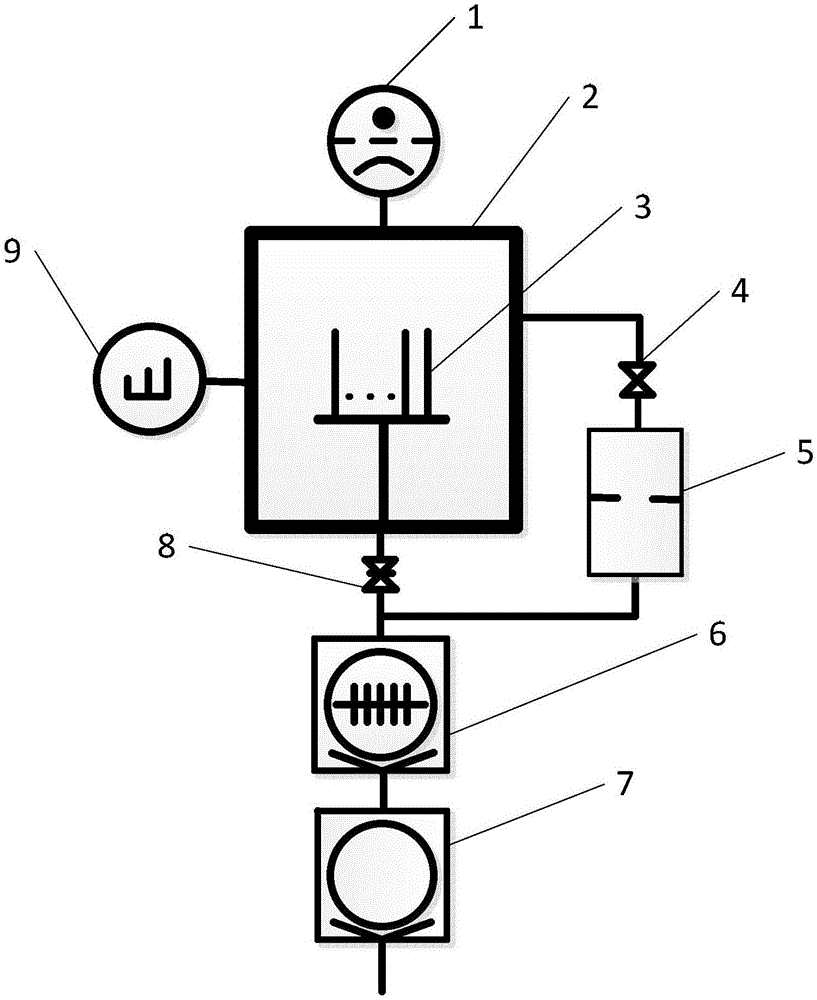

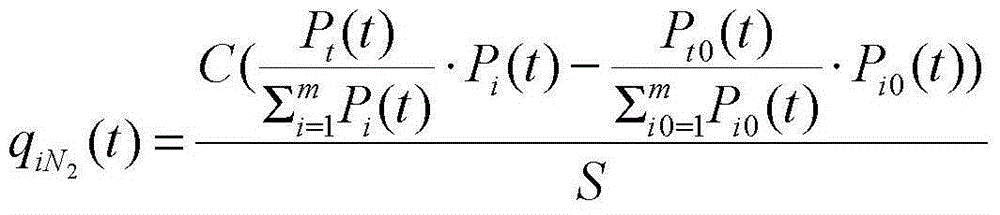

[0037] The measuring instrument of the present invention is a quadrupole mass spectrometer and a separation gauge, which respectively measure the background partial pressure and the background nitrogen equivalent total pressure of different gases when the measurement chamber is empty and contains samples, and then obtain the partial pressure release of the nitrogen equivalent of the sample. Gas rate.

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com