Making method for dried fig

A production method and technology of figs, which are applied in food preparation, application, food science, etc., can solve the problems of poor production and controlled temperature cleaning and washing, poor taste of dried figs, and affecting people's consumption, etc., to achieve good taste and color. Golden yellow without browning, uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

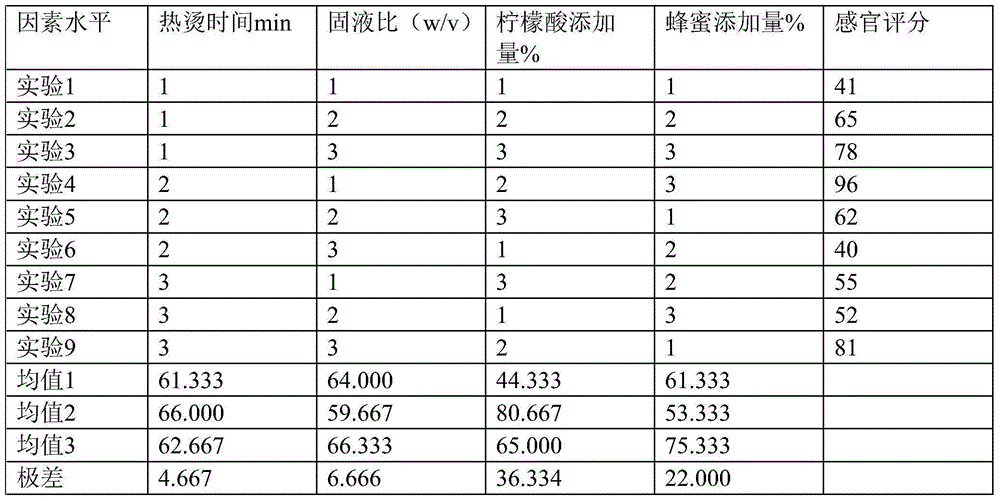

[0026] A method for making dried figs, comprising the following steps:

[0027] (1) Raw material selection: select the mature figs with a round shape and full grains as the raw material;

[0028] (2) Washing and blanching: the figs selected in step (1) are washed in hot water and blanched, the mass volume ratio of the figs to water is 1:5, the washing temperature is controlled at 100°C, and the blanching time is 1min , adding citric acid and honey in the blanching process, the mass fraction of the citric acid is 0.1%, and the mass fraction of the honey is 3%;

[0029] (3) Ventilation and dehumidification: dehumidification and drying are carried out under ventilation, without absolute drying, and dried to a moisture content of 25%;

[0030] (4) Reverse baking: bake the figs obtained in step (3) in a roasting machine, the baking temperature is controlled at 200°C, and the method of reversing baking is used for baking; Dried fruit, the specific steps are as follows: After the f...

Embodiment 2

[0035] A method for making dried figs, comprising the following steps:

[0036] (1) Raw material selection: choose ripe figs with rounded shape and full grains as the main raw material for making;

[0037] (2) Washing and blanching: the figs selected in step (1) are washed in hot water and blanched, the mass volume ratio of the figs to water is 1:30, the washing temperature is controlled at 120°C, and the blanching time is 3min , adding citric acid and honey in the blanching process, the mass fraction of the citric acid is 0.6%, and the mass fraction of the honey is 8%;

[0038] (3) Ventilation and dehumidification: dehumidification and drying are carried out under ventilation, without absolute drying, and dried to a moisture content of 30%;

[0039] (4) Reverse baking: bake the figs obtained in step (3) in a roasting machine, the baking temperature is controlled at 300°C, and the method of reversing baking is used for baking; during this period, kneading and pressing Dried fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com