Processing method of rice wine radix salviae miltiorrhizae slices

The technology of wine Salvia and Salvia miltiorrhiza is applied in the field of preparation of traditional Chinese medicine pieces, can solve the problems of frying, high frying temperature, long frying time, etc., and achieves the effects of stable product quality, low frying temperature and short frying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 The frying container that the present invention adopts:

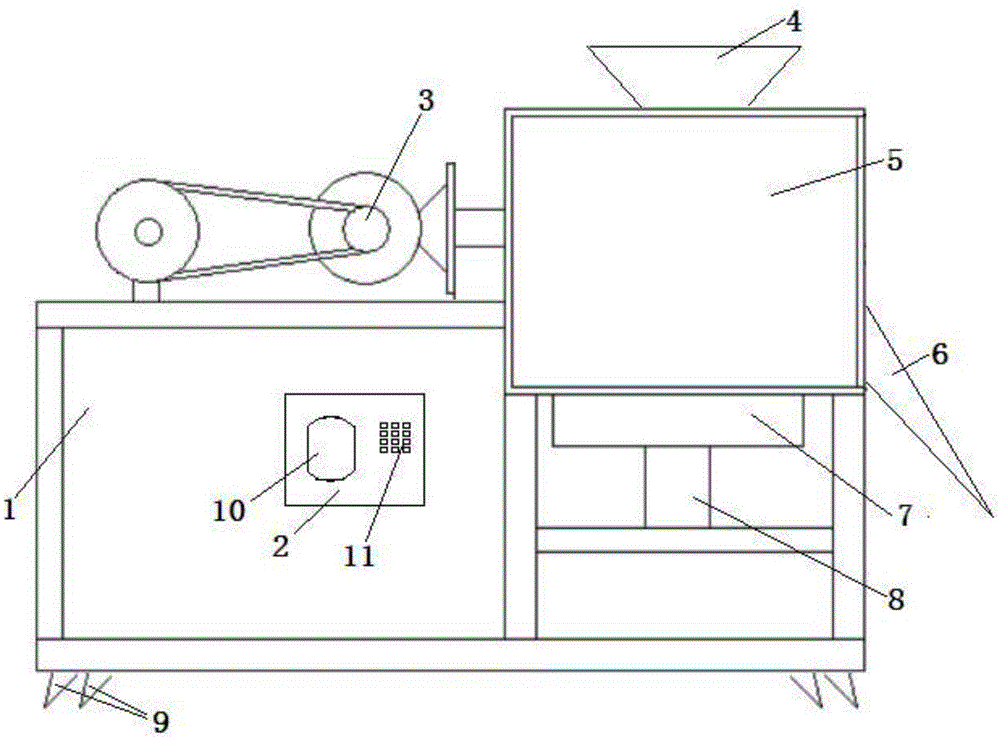

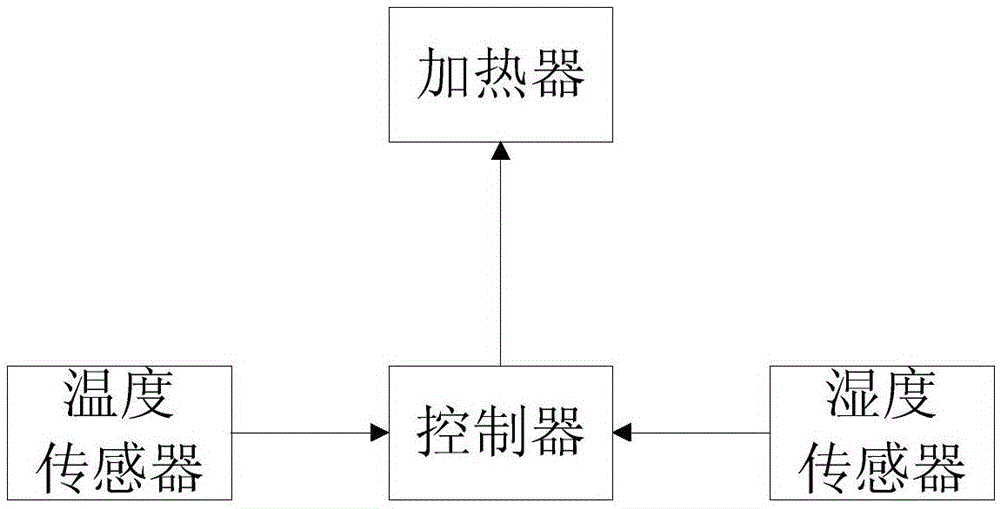

[0050] Such as figure 1 , 2 As shown, including: controller 2, temperature sensor, humidity sensor, heater 7 and boiler 5;

[0051]The medicinal materials to be fried are placed inside the boiler 5, and the boiler 5 is equipped with a temperature sensor and a humidity sensor. The signal output end of the temperature sensor is connected to the temperature signal receiving end of the controller 2, and the signal output end of the humidity sensor is connected to the humidity signal receiving end of the controller 2. The control end of the controller 2 is connected to the temperature adjustment control end of the heater 7. The temperature sensor and the humidity sensor obtain the internal temperature and humidity data of the boiler 5, and the heater 7 is controlled by the controller 2 to perform heating and frying.

[0052] The beneficial effect of the above technical solution is: the temperature and h...

Embodiment 2

[0070] The selection of the amount of water added and the soaking time of the medicinal material soaking process:

[0071] 1. Investigation of water absorption of medicinal materials

[0072] Weigh about 100g of Danshen medicinal material, put it in a beaker, measure 1000mL of distilled water, add it to the beaker, seal it, soak for 24 hours, and use the difference in distilled water volume change as an index to investigate the maximum water absorption of Danshen medicinal material within 24 hours. Results After infiltration of Scrophulariaceae for 24 hours, the remaining volume of distilled water was 895 mL, and the volume change was 105 mL. The maximum water absorption of Salvia miltiorrhiza within 24 hours is 1.05mL per 1g of medicinal material.

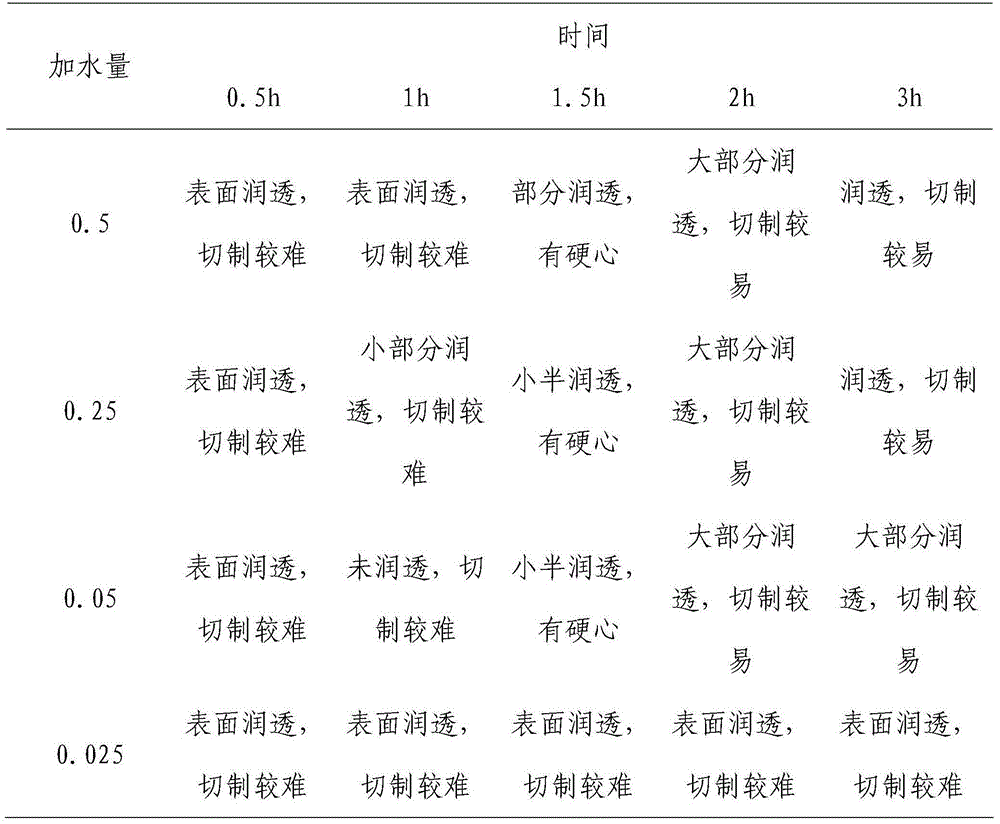

[0073] On the basis of the water absorption test of the salvia miltiorrhiza, take appropriate amount of the medicinal material, measure distilled water equivalent to 0.5, 0.25, 0.05, and 0.025 times the mass of the medicinal mate...

Embodiment 3

[0078] Take the medicinal material of Danshen, remove impurities and residual stems, and wash; considering the energy consumption of drying and the factors of processing time, choose to add water with 0.05 times the weight of the medicinal material of Danshen, and soak for 2 hours.

[0079] Cut the infiltrated Danshen medicinal material into thin slices of 1-2mm thickness, 2-4mm thin slices or short sections of 5-8mm, and then dry to obtain Danshen slices or short sections of Danshen, and then add rice wine with a mass of 10% of the mass of Danshen Aqueous solution, the mass concentration of yellow rice wine aqueous solution is 10%. Mix well, simmer for 3 hours, then place in the frying container of Example 1, fry at 150°C for 6 minutes, take it out, let it cool, and measure the amount of salvianolic acid B in decoction pieces with different thicknesses and the content of alcohol extracts respectively. amount, the results are shown in Table 2

[0080] The investigation result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com