Ultrafine wall-breaking grinding method for salviae miltiorrhizae

A technology of ultra-fine wall-breaking crushing and salvia miltiorrhiza, which is applied in the field of medicine, can solve the problems of long crushing time, low powder yield of tanshinone, high loss rate of salvianolic acid B, etc., and achieve the effect of short processing time and high powder yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

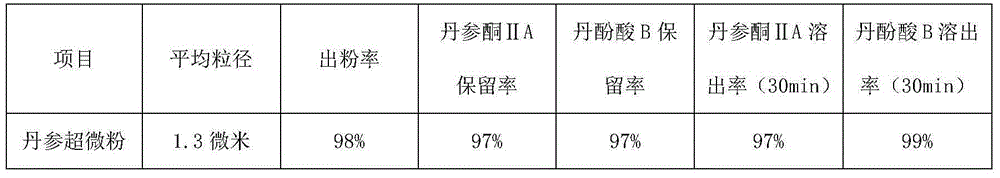

[0016] 1kg of Salvia miltiorrhiza is routinely pulverized and passed through a 80-100 mesh sieve to obtain fine powder of Salvia miltiorrhiza; mix 5g of sorbitol and 5g of phenylalanine evenly to obtain a mixed powder of sorbitol-phenylalanine; mix the fine powder of salvia miltiorrhiza with sorbitol-benzene The alanine mixed powder was mixed evenly, and pulverized by WZJ12J vibrating ultrafine pulverizer for 1 hour, and the obtained powder was measured for average particle size, powder yield, retention rate of tanshinone ⅡA and salvianolic acid B, and dissolution rate of tanshinone ⅡA and salvianolic acid B , the results are shown in Table 1.

[0017] The relevant data of the salvia miltiorrhiza superfine powder of table 1 embodiment 1

[0018]

Embodiment 2

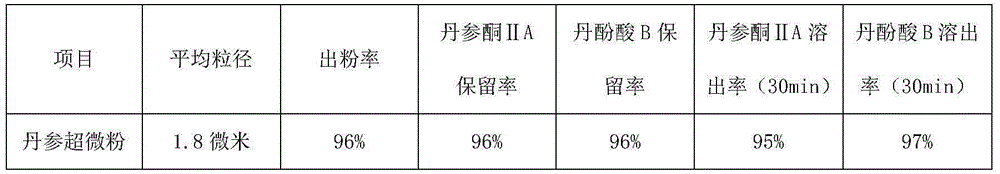

[0020] 1 kg of Salvia Miltiorrhiza is conventionally pulverized, and passed through a 80-100 mesh sieve to obtain fine powder of Salvia Miltiorrhiza; 2.5 g of sorbitol and 2.5 g of phenylalanine are uniformly mixed to obtain a mixed powder of sorbitol-phenylalanine; -Phenylalanine mixed powder is mixed evenly, and pulverized by WZJ12J vibrating ultrafine pulverizer for 1 hour, and the obtained powder is measured for average particle size, powder yield, retention rate of tanshinone ⅡA and salvianolic acid B, and tanshinone ⅡA and salvianolic acid B Dissolution rate, the results are shown in Table 2.

[0021] The relevant data of the salvia miltiorrhiza superfine powder of table 2 embodiment 2

[0022]

Embodiment 3

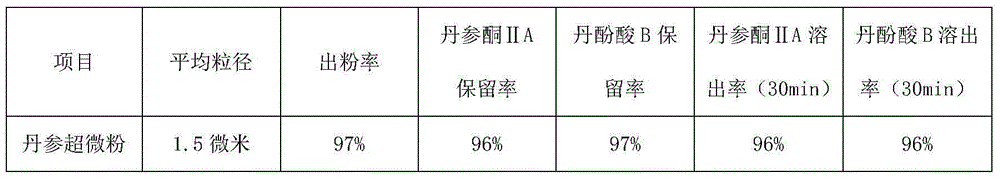

[0024] 1kg of Salvia miltiorrhiza is conventionally pulverized and passed through a 80-100 mesh sieve to obtain fine powder of Salvia miltiorrhiza; mix 4g of sorbitol and 4g of phenylalanine evenly to obtain a mixed powder of sorbitol-phenylalanine; mix the fine powder of salvia miltiorrhiza with sorbitol-benzene The alanine mixed powder was mixed evenly, and pulverized by WZJ12J vibrating ultrafine pulverizer for 1 hour, and the obtained powder was measured for average particle size, powder yield, retention rate of tanshinone ⅡA and salvianolic acid B, and dissolution rate of tanshinone ⅡA and salvianolic acid B , the results are shown in Table 3.

[0025] The relevant data of the superfine powder of salvia miltiorrhiza in table 3 embodiment 3

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com