Micro-fluidic chip heat dissipation device, and manufacturing method thereof

A technology of microfluidic chips and cooling devices, applied in the field of microfluidics, can solve the problems that cannot be realized, limit the application range and effect of chip materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

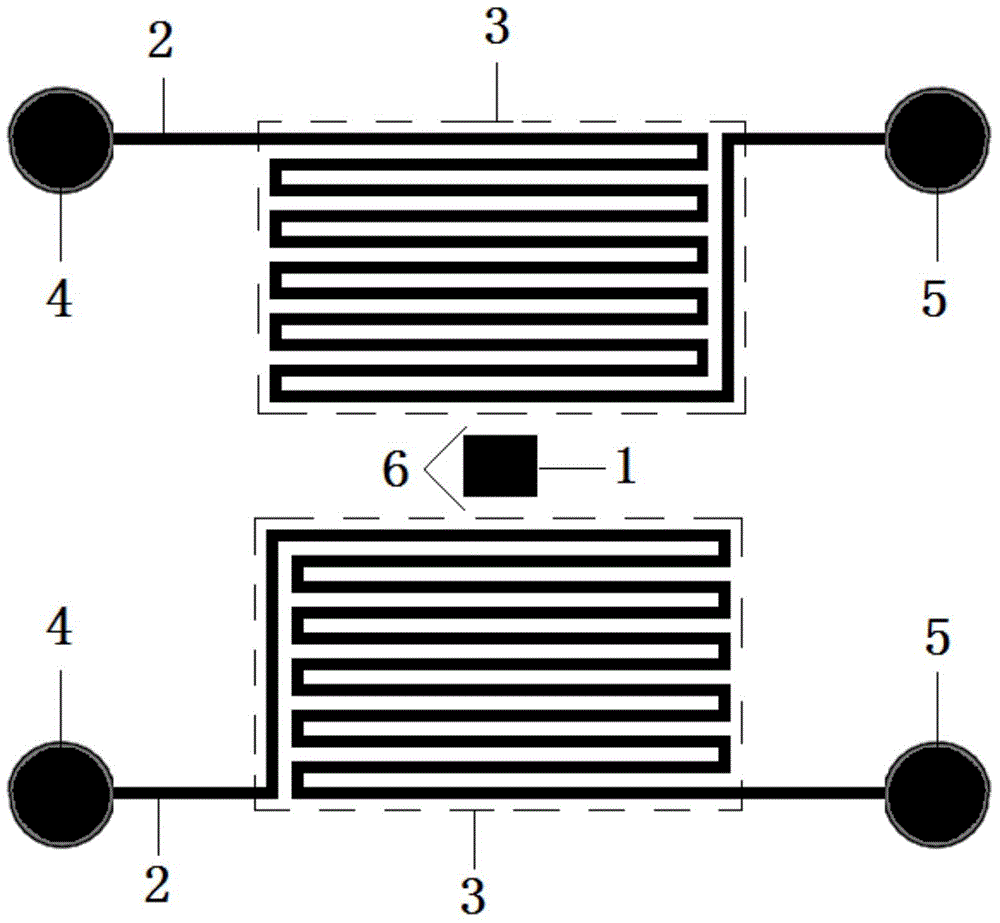

[0047] Such as figure 1 As shown, the present embodiment provides a cooling device for a microfluidic chip, including a heat generating region 1 and a microfluidic channel 2 with high thermal conductivity. In this embodiment, the heat generating region 1 is rectangular when viewed from top to bottom. High thermal conductivity micro-channels 2 are horizontally arranged in parallel in series (end-to-end connection of sub-channels), forming an enhanced heat transfer area 3 (first heat transfer area). The two enhanced heat transfer regions 3 are arranged symmetrically on both sides of the heat generating region 1. The enhanced heat transfer region 3 and the heat generating region 1 are at the same level and at the same height. The size is not greater than the width of the high thermal conductivity micro flow channel 2 . The heat dissipation device for the microfluidic chip provided in this embodiment facilitates conduction and diffusion of heat in the heat generating region 1 al...

Embodiment 2

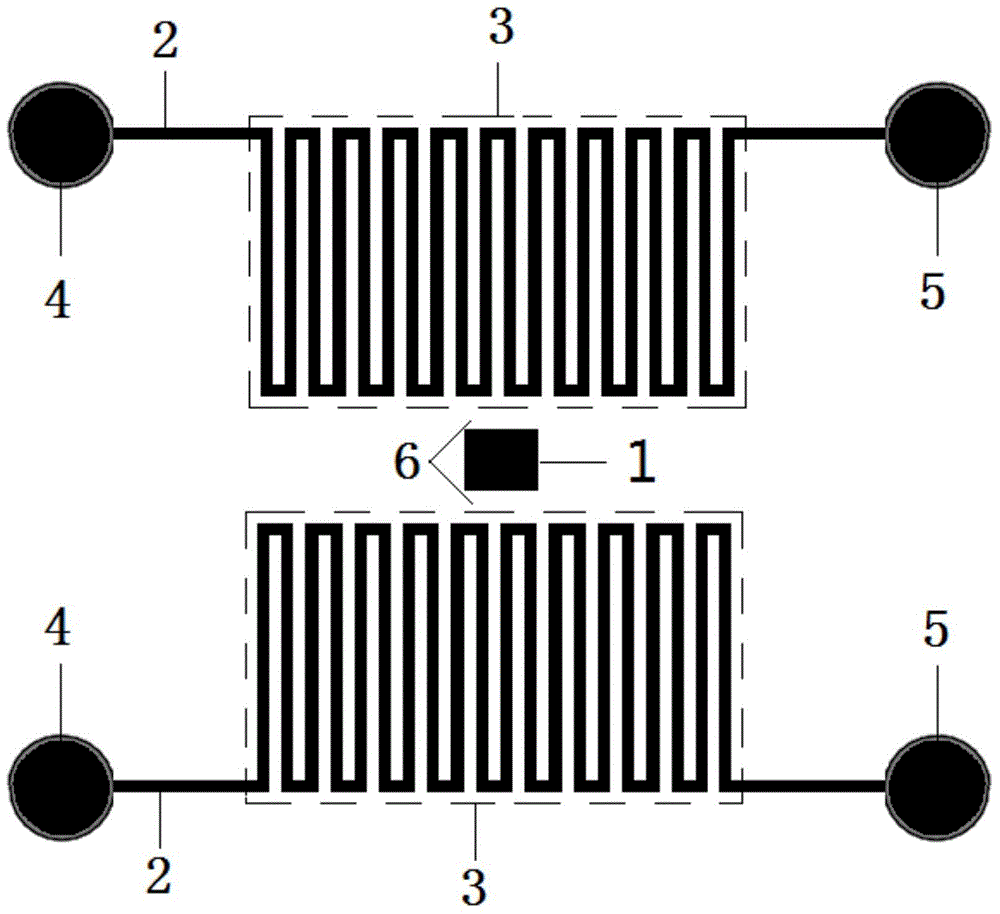

[0055] Such as figure 2 As shown, the microfluidic chip cooling device provided in this embodiment includes a heat generating region 1 and a high thermal conductivity microchannel 2 . In this embodiment, the heat generating region 1 is rectangular when viewed from top to bottom. The high thermal conductivity micro-channels 2 are vertically arranged in parallel and in series to form an enhanced heat transfer area 3 (first heat transfer area). The two enhanced heat transfer regions 3 are arranged symmetrically on both sides of the heat generating region 1, and the enhanced heat transfer region 3 is at the same level and at the same height as the heat generating region 1. ), the size of the gap is not greater than the width of the high thermal conductivity micro-channel 2 . The microfluidic chip cooling device provided in this embodiment facilitates the conduction and diffusion of heat in the heat generating region 1 along the vertical and horizontal directions. It should be ...

Embodiment 3

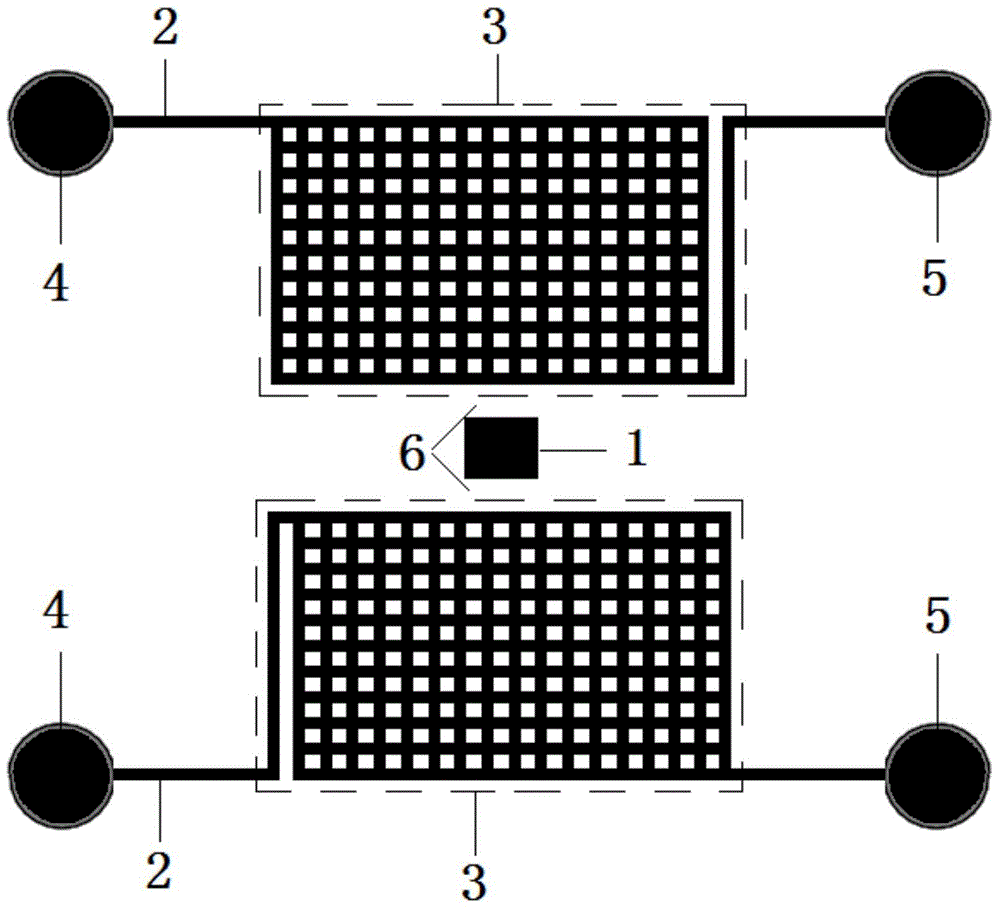

[0063] Such as image 3 As shown, the microfluidic chip cooling device provided in this embodiment includes a heat generating region 1 and a high thermal conductivity microchannel 2 . In this embodiment, the heat generating region 1 is rectangular when viewed from top to bottom. High thermal conductivity micro-channels 2 are vertically arranged in a staggered manner to form an enhanced heat transfer area 3 (third heat transfer area). Two enhanced heat transfer regions 3 are arranged symmetrically on both sides of the heat generating region 1, the enhanced heat transfer region 3 is at the same level and at the same height as the heat generating region 1, and at the same time, the two are separated by a gap formed by a micro-scale film 6. The size of the gap is not larger than the width of the high thermal conductivity micro flow channel 2 . It should be understood that image 3 The enhanced heat transfer area 3 can also be set to maintain a certain inclination angle (0-90°) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com