Method for removing sodium carbonate in solution

A sodium carbonate and solution technology, which is applied in the direction of hydrazine, nitrogen and non-metallic compounds, can solve the problems of high economic cost and complicated process, and achieve the effect of improving economic benefits, simple process operation and easy treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

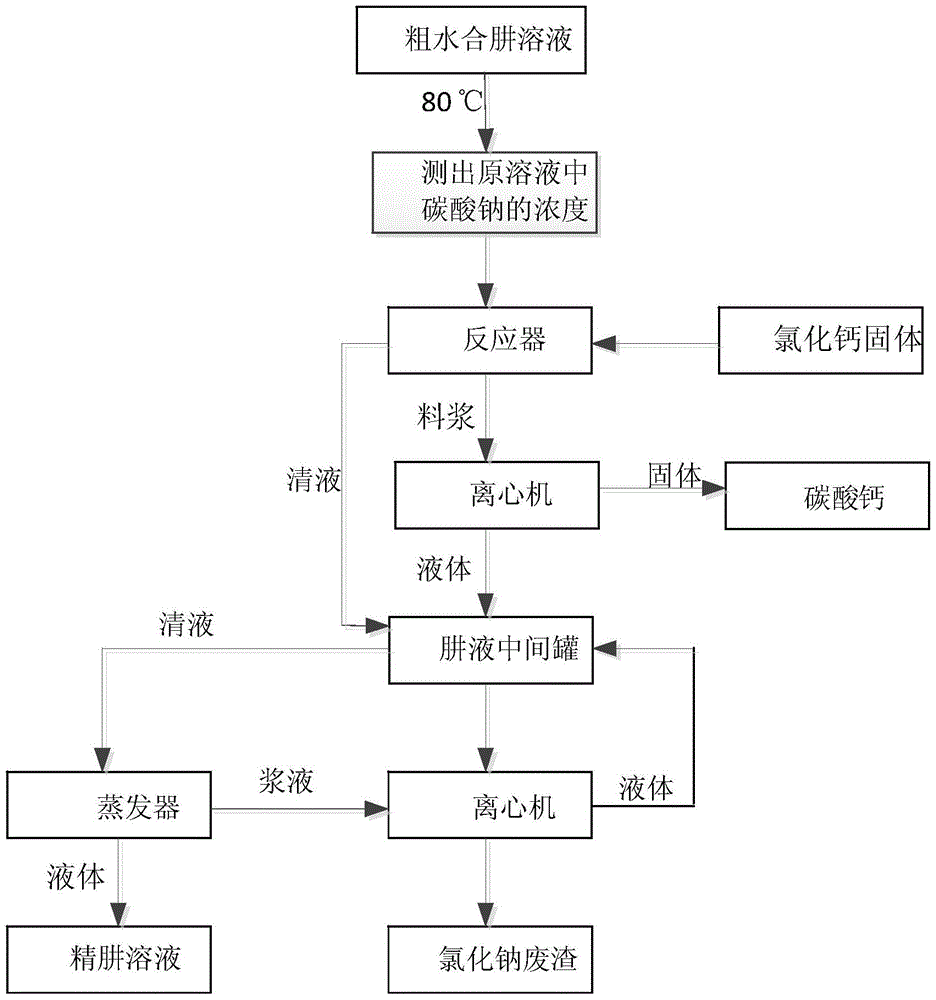

Method used

Image

Examples

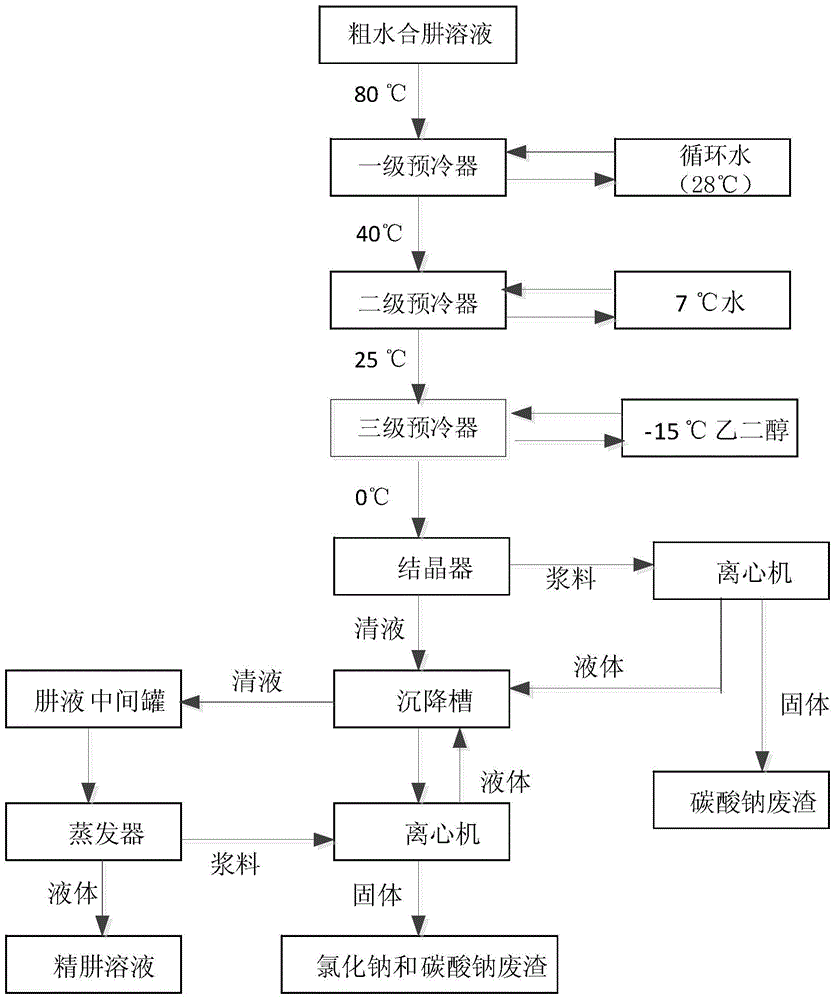

Embodiment 2

[0076] see figure 2 , take a sample from the former thick hydrazine hydrate solution, and calculate the total amount of sodium carbonate in the former thick hydrazine hydrate solution, the volume of the clear liquid that this stage unit time (1 hour) is processed is 150 * 10 3 L, according to the molar ratio of calcium chloride content and sodium carbonate content is 1~1.2:1, add calcium chloride solid to the original crude hydrazine hydrate solution, and make calcium chloride and sodium carbonate fully react, then react the The product is subjected to solid-liquid separation where a centrifuge is used to reduce mother liquor entrained on the solids. The obtained serum is measured to be 60°C at this time. Since the process is a natural cooling without resorting to the loss of external heat, this process does not consume external energy, that is, Q 外2 = 0KJ. Compared with the cooling process in embodiment one, save altogether:

[0077] Q 降温节省 =Q 外1 -Q 外2 =7.94×10 10 -0=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com