A kind of nanometer boron phosphate catalyzes charcoal flame retardant epoxy resin and preparation method thereof

A technology of epoxy resin and boron phosphate, which is applied in the field of flame retardant materials to achieve the effects of high flame retardant efficiency, low price and adjustable chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0038] E44 84.5%,

[0039] m-PDA 10.5%,

[0040] nano-BP 1.27 (The atomic molar ratio of boron to phosphorus is 1.27) 5.0%,

[0041] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

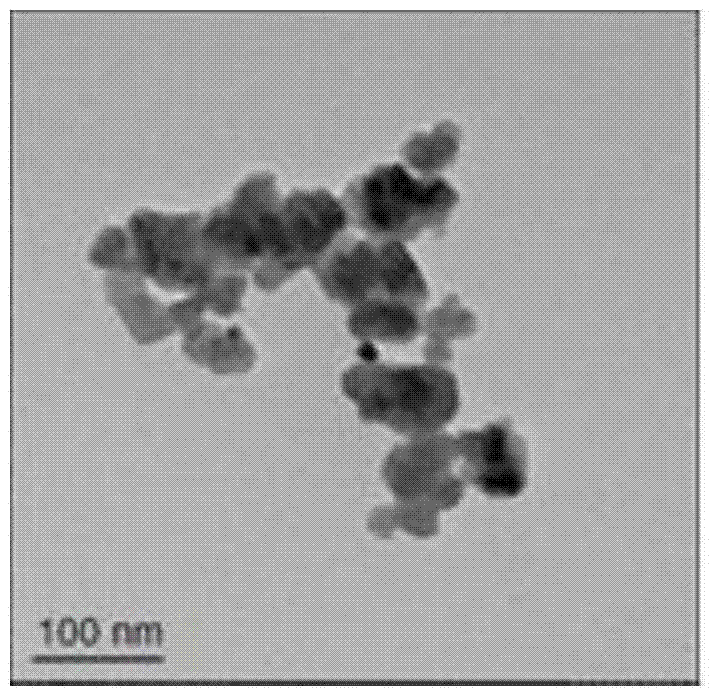

[0042] (1) Add boric acid (1.25mol) and phosphoric acid (1mol) into a beaker, stir at 110°C for 25min, and keep warm for 4h to obtain white solid 1; put white solid 1 in a tube furnace, and adjust the heating rate to 5°C / min, heated up to 500°C, calcined for 8h, cooled with the furnace, washed 3 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 40-60nm (such as figure 1 Shown), the actual at...

Embodiment 2

[0048] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0049] E44 84.5%,

[0050] m-PDA 10.5%,

[0051] nano-BP 1.06 (The atomic molar ratio of boron to phosphorus is 1.06) 5.0%,

[0052] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

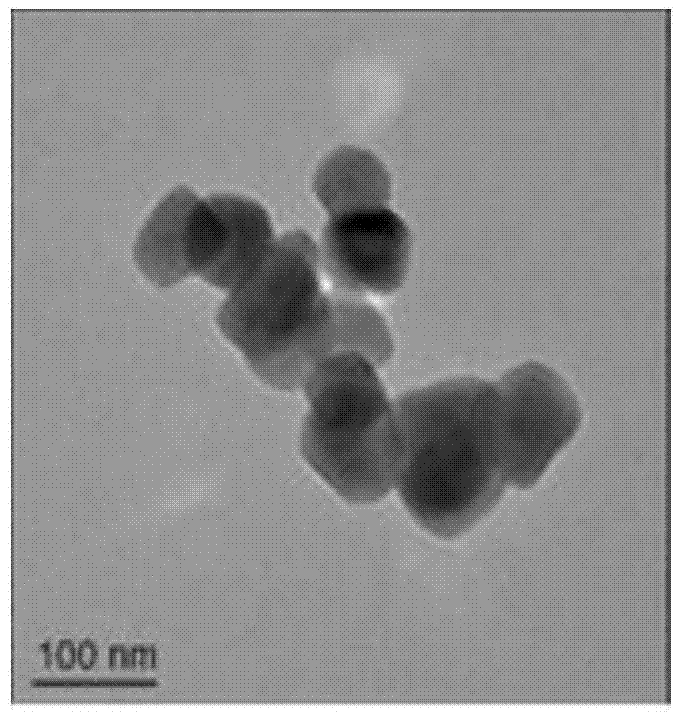

[0053] (1) Add boric acid (1mol) and phosphoric acid (1mol) into a beaker, stir at 120°C for 35min, and keep warm for 5h to obtain a white solid 1; put the white solid 1 in a tube furnace, and adjust the heating rate to 8°C / min, heated up to 700°C, calcined for 12 hours, cooled with the furnace, washed 5 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 60-80nm (such as figure 2 Shown), the...

Embodiment 3

[0059] A kind of nanometer boron phosphate is catalyzed into charcoal flame-retardant epoxy resin, taking described epoxy resin total mass (300g) as 100%, each component and its mass percentage are as follows:

[0060] E44 84.5%,

[0061] m-PDA 10.5%,

[0062] nano-BP 0.84 (The atomic molar ratio of boron to phosphorus is 0.84) 5.0%,

[0063] A preparation method of nano-boron phosphate catalyzed into charcoal and flame-retardant epoxy resin as described in this embodiment, the specific steps of the method are as follows:

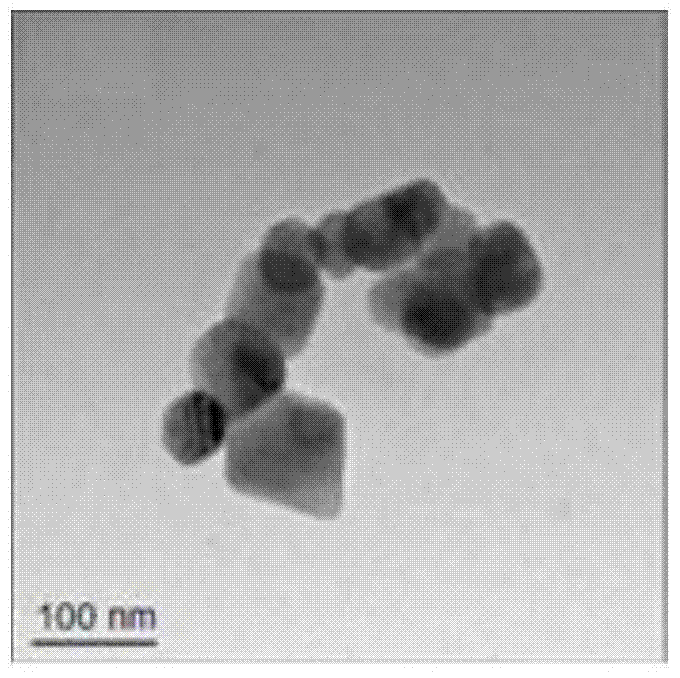

[0064] (1) Add boric acid (0.8mol) and phosphoric acid (1mol) into a beaker, stir at 115°C for 30min, and keep warm for 4.5h to obtain a white solid 1; put the white solid 1 in a tube furnace, and adjust the heating rate to 7 °C / min, heat up to 600 °C, calcined for 10 h, cooled with the furnace, washed 4 times, and dried in vacuum to obtain solid acid nano boron phosphate white powder with a particle size of about 40-80 nm (such as image 3 Shown), the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com