Environment-friendly cement fence coating

An environmentally friendly, cement-based technology, applied in anti-corrosion coatings, coatings, etc., can solve problems that affect performance and pollute the environment, achieve long service life, wide absorption range, and improve decorative performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

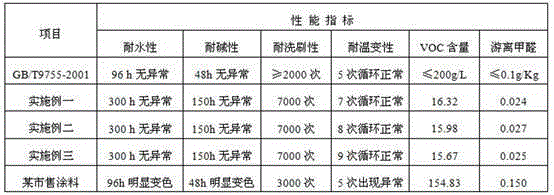

Examples

Embodiment 1

[0012] An environment-friendly cement fence coating of the present invention comprises the following raw materials in parts by weight: pure acrylic emulsion 20g, pigment 10g, filler 20g, deionized water 10g, Tween-801g, Span-801g, substituted acrylate 1g, hydroxyl Ethyl cellulose 1g, sodium silicate 1g, magnesium oxide 1g.

Embodiment 2

[0014] An environment-friendly cement fence coating of the present invention comprises the following raw materials in parts by weight: pure acrylic emulsion 30g, pigment 10g, filler 20g, deionized water 20g, Tween-8010g, Span-8010g, substituted acrylate 5g, hydroxyl Ethyl cellulose 5g, sodium silicate 5g, magnesium oxide 5g.

Embodiment 3

[0016] An environment-friendly cement fence coating of the present invention comprises the following raw materials in parts by weight: pure acrylic emulsion 25g, pigment 15g, filler 25g, deionized water 15g, Tween-807g, Span-807g, substituted acrylate 3g, hydroxyl Ethyl cellulose 3g, sodium silicate 3g, magnesium oxide 3g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com