Method for improving concentration of alcohol substances in fermented product of anaerobic gas-feeding microbes

A microbial fermentation and microbial technology, applied in the direction of fermentation, bacteria, etc., can solve the problems of secondary environmental pollution and complex process, and achieve the effect of increasing value and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

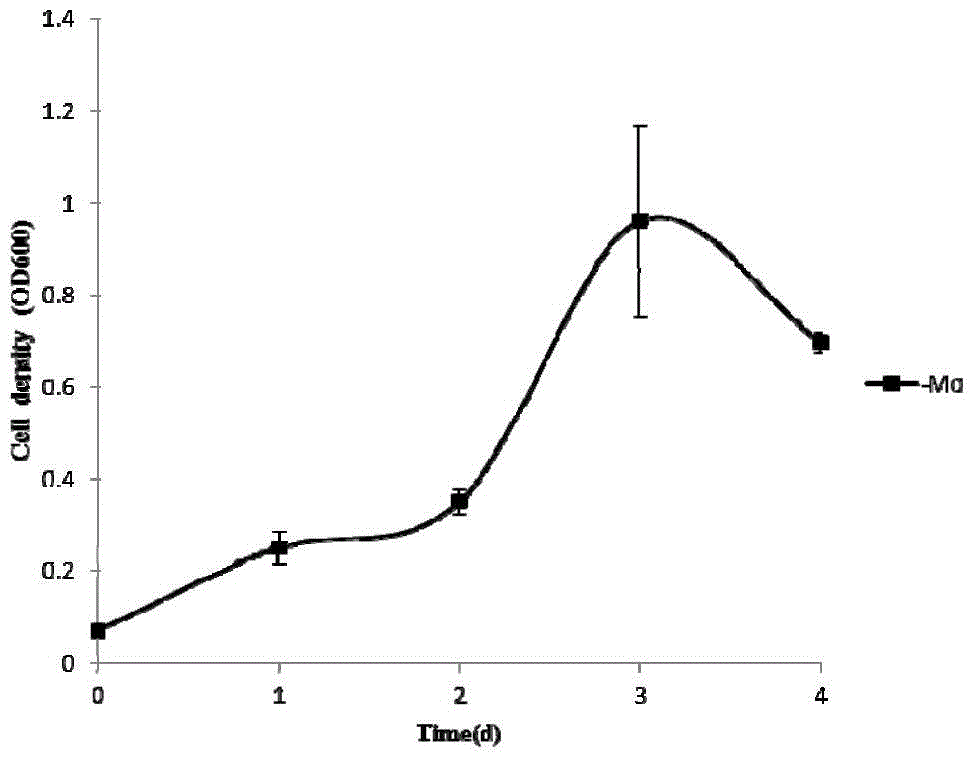

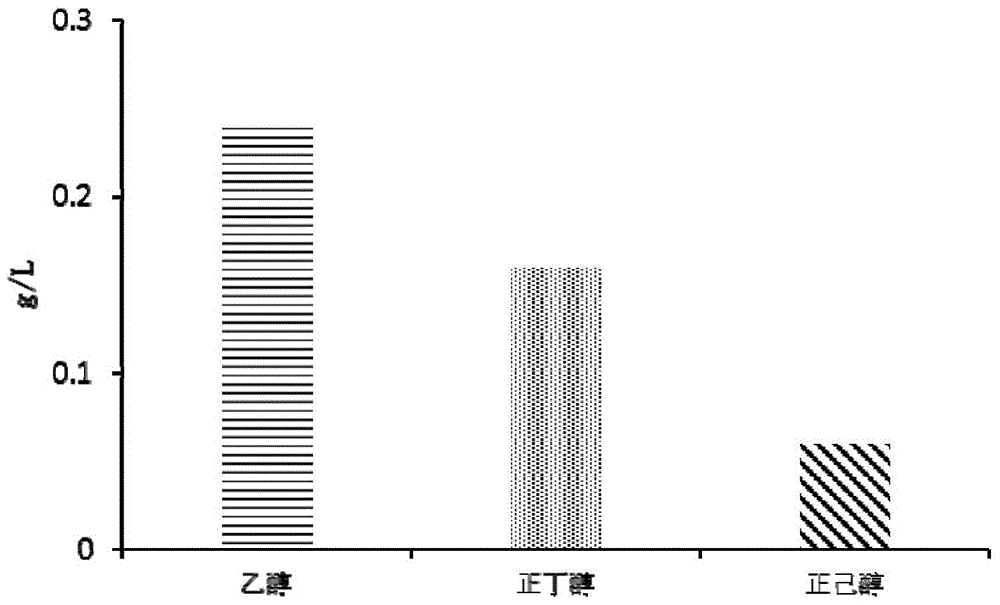

[0031] In the basal culture medium, molybdate ions were not added. After 4 days of constant temperature shaking culture, samples were taken every 24 hours to detect the growth of microorganisms; samples taken on the fourth day were used to detect the concentrations of ethanol, n-butanol and n-hexanol in the fermentation broth by gas chromatography. Strain reached 0.96 in OD600 on the fourth day, and began to enter the decline period on the fourth day ( figure 1 ). On the fourth day, the product concentrations of ethanol, n-butanol and n-hexanol were 0.24, 0.16 and 0.06 g / L ( figure 2 ).

Embodiment 2

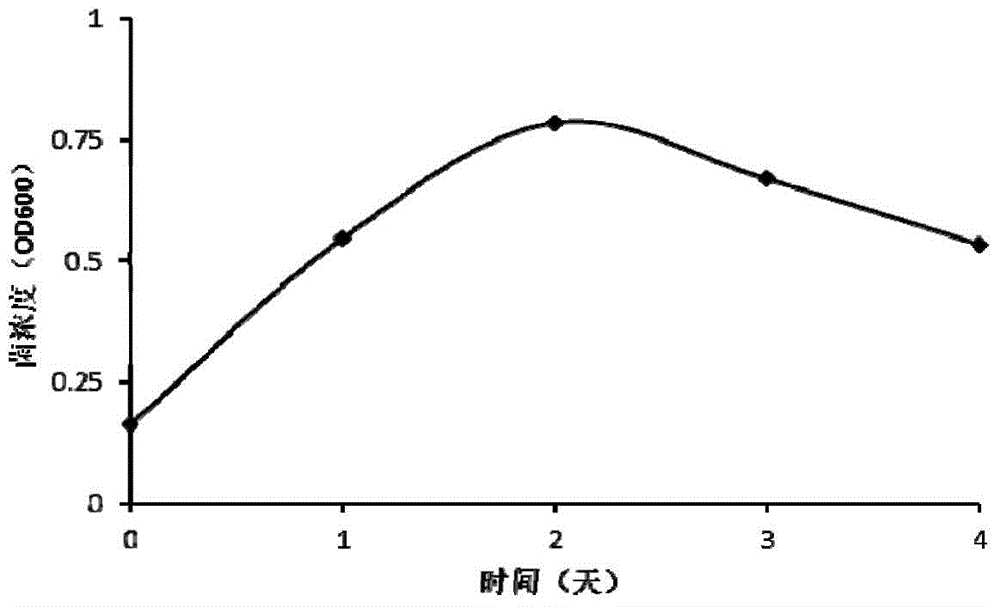

[0033] In the basal culture solution, add molybdate ions at a final concentration of 0.1 mg / L. After 4 days of constant temperature shaking culture, samples were taken every 24 hours to detect the growth of microorganisms; samples taken on the fourth day were used to detect the concentrations of ethanol, n-butanol and n-hexanol in the fermentation broth by gas chromatography. The bacterial strain reached 0.79 in OD600 on the third day, and began to enter the decline period on the fourth day ( image 3 ). On the fourth day, the ethanol production was 0.07g / L, n-butanol and n-hexanol could not be detected, and the growth of bacteria was also poor.

Embodiment 3

[0035] In the basal culture solution, add molybdate ions at a final concentration of 1 mg / L. After 4 days of constant temperature shaking culture, samples were taken every 24 hours to detect the growth of microorganisms; samples taken on the fourth day were used to detect the concentrations of ethanol, n-butanol and n-hexanol in the fermentation broth by gas chromatography. The highest concentration of bacterial strain can only reach OD600=0.35 ( Figure 4 ). No alcohols could be detected in the fermentation product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com