Oxide dispersion strengthened ferrite/martensitic steel and preparation method thereof

A technology of dispersion strengthening and martensitic steel, which is applied in the field of oxide dispersion strengthening ferrite/martensitic steel and its preparation, can solve the problems of high requirements in the preparation and packaging process, phase transformation of encased samples, etc., and achieve enhanced resistance Corrosion ability, reducing oxygen content, and ensuring the effect of creep strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare 8.5%Cr, 1.2%W, 0.2%V, 0.2%Mn, 3.5%Al, 0.5%Zr, 0.35%Y 2 o 3 The purity of the above raw materials is 99.9%, the content of C and N is less than 0.1%, and the rest is Fe, and the above are mass percentages;

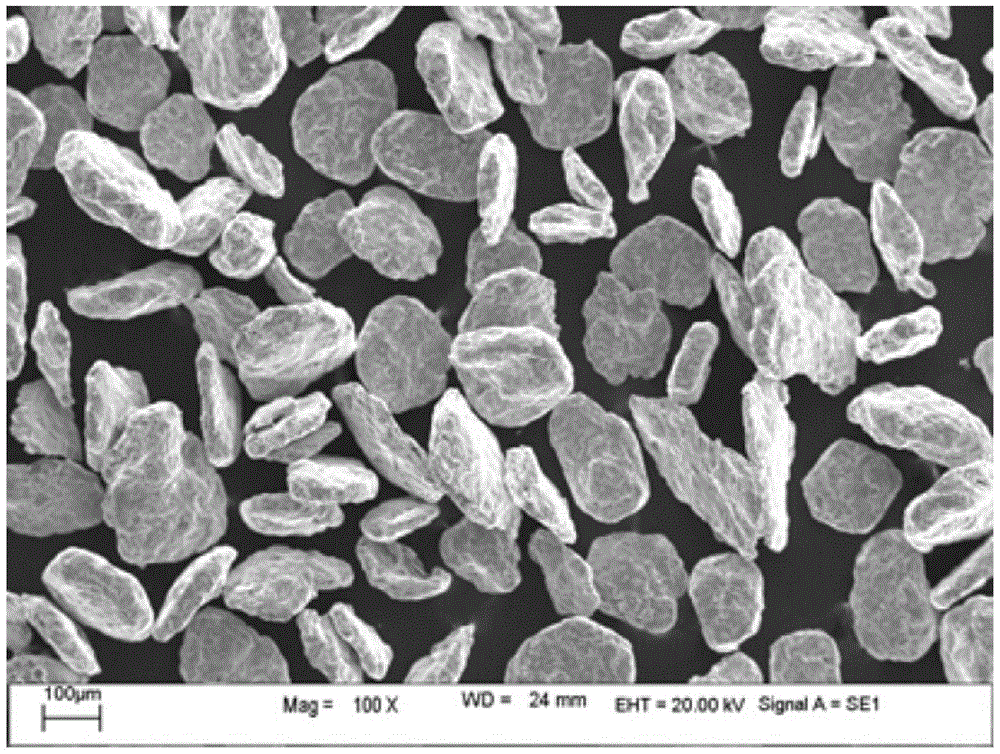

[0027] (2) will divide Y 2 o 3 All elements except , Zr, Al, etc. are prepared by Ar gas atomization method according to the mass percentage in step (1), the oxygen content is controlled below 0.04wt.%, and the particles with a particle size of 50-200 mesh are screened as mechanical powders. alloying spare powder;

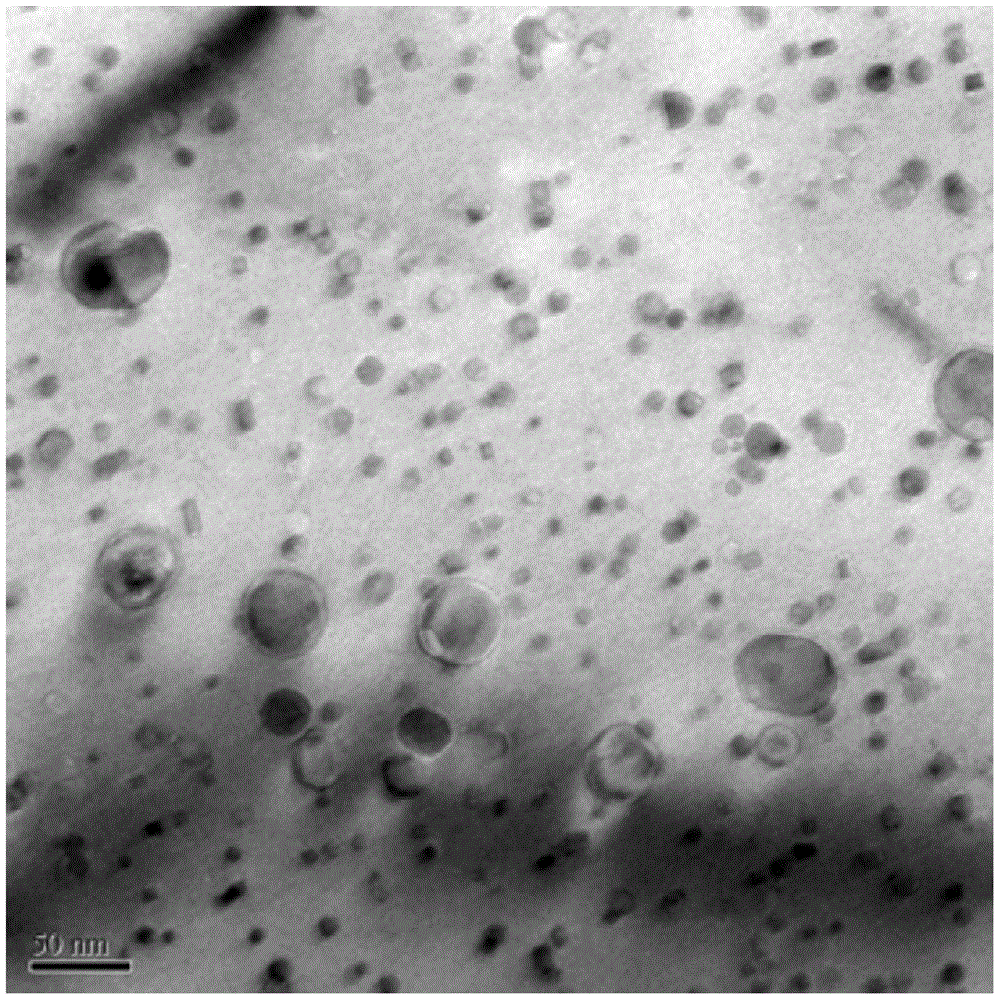

[0028] (3) Combine the above mechanically alloyed spare powder with Y in step (1) 2 o 3 , Zr, and Al are installed in the ball mill tank under the protection of Ar gas in the whole process in the hand box. The mechanical alloying parameters are: the ball-material ratio is 6:1, the ball mill medium is stainless steel balls, the speed is 300r / min, and the ball mill is cooled for 1 hour for 4 hours. Ball milling was carried out several time...

Embodiment 2

[0031] (1) Prepare 9%Cr, 1.8%W, 0.3%V, 0.2%Mn, 4.5%Al, 0.2%Hf, 0.4%Y 2 o 3 , the purity of the above raw materials is 99.9%, the content of C and N is less than 0.1%, and the rest is Fe, and the above are mass percentages;

[0032] (2) will divide Y 2 o 3 All elements except , Hf, Al, etc. are prepared by Ar gas atomization method according to the mass percentage in step (1), the oxygen content is controlled below 0.035wt.%, and the particles with a particle size of 50-200 mesh are screened as mechanical powders. alloying spare powder;

[0033] (3) Combine the above mechanically alloyed spare powder with Y in step (1) 2 o 3 , Hf, and Al are installed in the hand box under the protection of Ar gas throughout the whole process. The mechanical alloying parameters are: the ball-to-material ratio is 8:1, the ball-milling medium is stainless steel balls, the speed is 330r / min, and the ball mill is cooled for 1 hour for 2 hours Ball milling was carried out several times in hour...

Embodiment 3

[0036] (1) Prepare 10%Cr, 1.5%W, 0.2%V, 0.3%Mn, 5%Al, 0.3%Zr, 0.2%Hf, 0.45%Y 2 o 3 , the purity of the above raw materials is 99.9%, the content of C and N is less than 0.1%, and the rest is Fe, and the above are mass percentages;

[0037] (2) will divide Y 2 o 3 All elements except , Hf, Al, etc. are prepared by Ar gas atomization method according to the mass percentage in step (1), the oxygen content is controlled below 0.04wt.%, and the particles with a particle size of 50-200 mesh are screened as mechanical powders. alloying spare powder;

[0038] (3) Combine the above mechanically alloyed spare powder with Y in step (1) 2 o 3 , Zr, Hf, and Al are placed in the ball mill tank under the protection of Ar gas in the whole process in the hand-held box. The mechanical alloying parameters are: the ball-to-material ratio is 7:1, the ball-milling medium is stainless steel balls, and the speed is 380r / min. The method of cooling for 1 hour was carried out multiple times for ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com