Nano-copper-titanium alloy and preparation method thereof

A titanium alloy and nano-copper technology, which is applied in the field of nano-copper-titanium alloy and its preparation, can solve the problems of lack of high-temperature thermal stability of copper-titanium alloy, no very outstanding comprehensive effect has been achieved, and the high-temperature stability of the alloy needs to be improved. The effect of short cycle, short smelting time and less precipitation of titanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

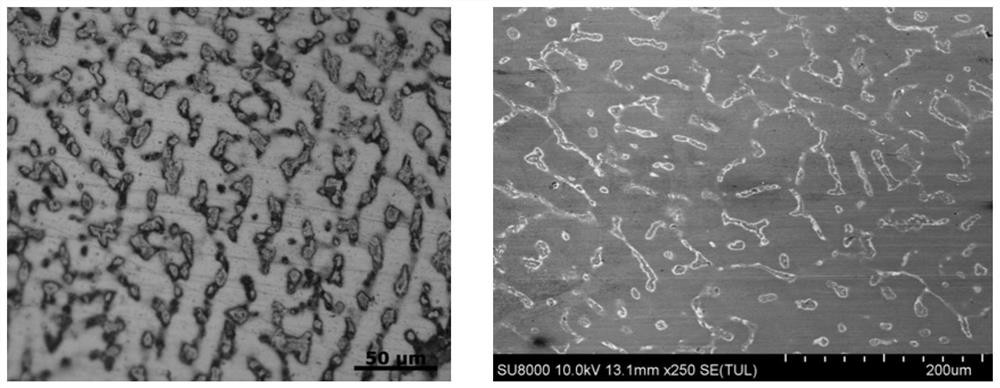

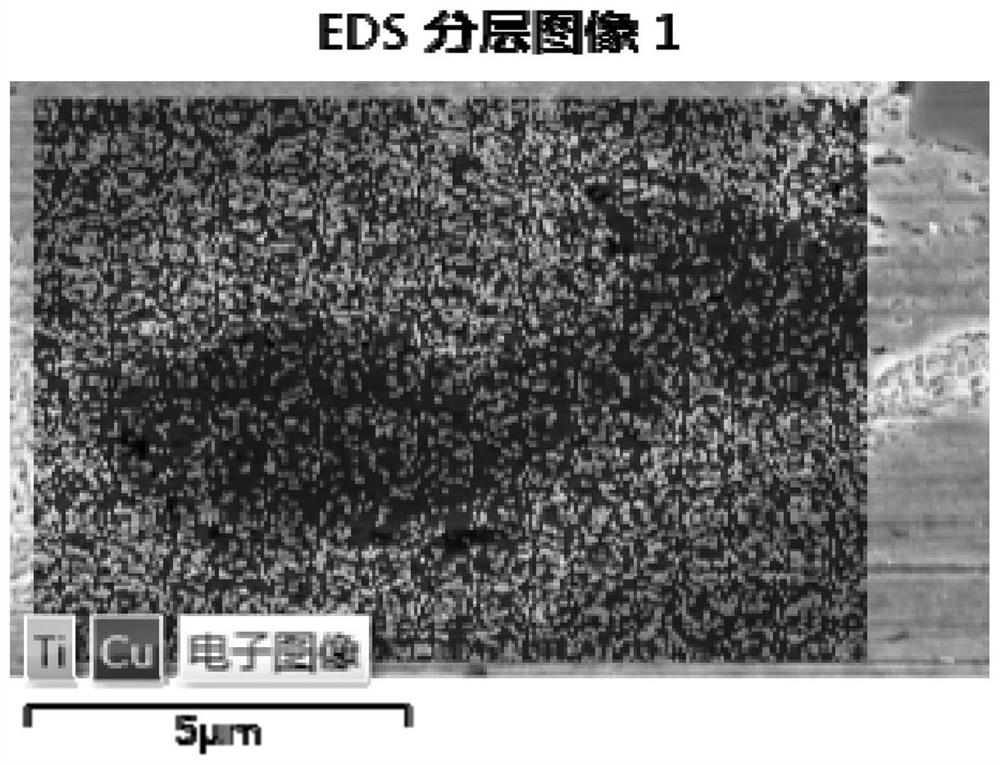

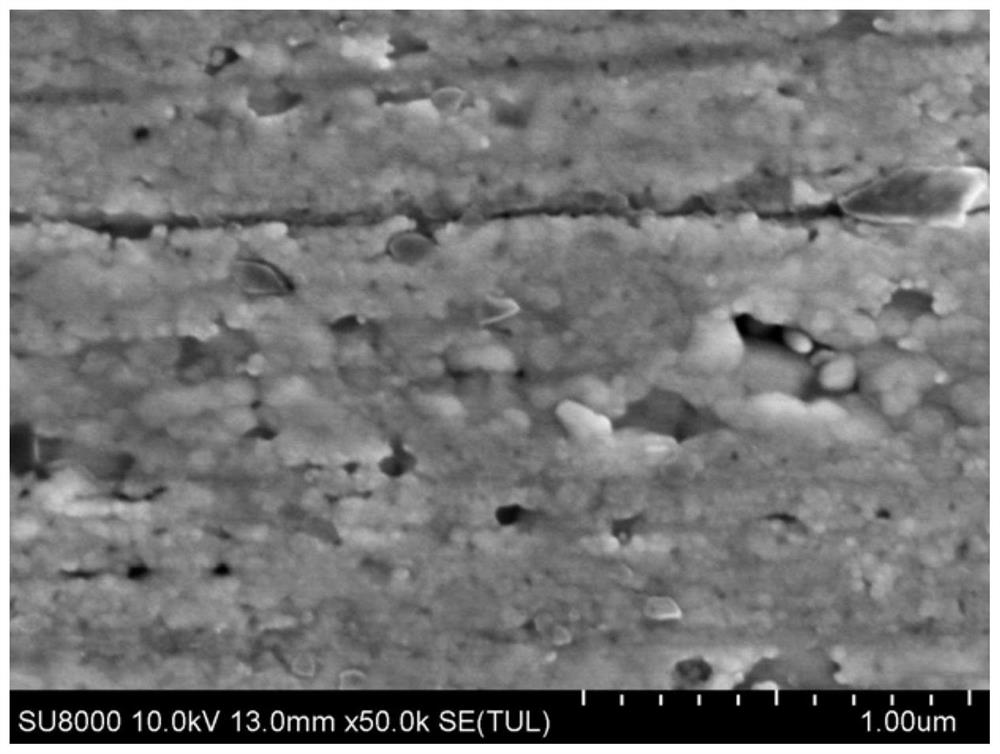

Image

Examples

preparation example Construction

[0029] The preparation method of nano-copper-titanium alloy of the present invention comprises the following steps:

[0030] a. Put copper and titanium into the same copper crucible of the electric arc melting furnace, and then seal it to remove oxygen in the electric arc melting furnace;

[0031] b. Adjust the current to melt both copper and titanium, then stir and smelt for 40-60 seconds, then turn off the current to cool;

[0032] c. Repeat step b at least once to obtain a nano-copper-titanium alloy.

[0033] The method of the invention can obtain the nano-copper-titanium alloy at one time, the steps are simple, the required equipment is simple, the operation is fast, the preparation cycle is short and the cost is low, and the preparation of the alloy can be realized within a few minutes. Moreover, the prepared nano-copper-titanium alloy has good high temperature stability, better plastic deformation ability at room temperature, and wider application range.

[0034] For l...

Embodiment 1

[0050] Binary Cu-4Ti alloy, its composition is Ti 4wt%, the rest is copper and unavoidable impurities. The concrete steps of its preparation are:

[0051] Step 1: placing a zirconium block in one of the crucibles in the cavity of the electric arc melting furnace;

[0052] Step 2: Put the copper block and the titanium block into one of the copper crucibles in the electric arc melting furnace with a mass fraction ratio of 96:4; then clean the cavity to reduce impurities such as oxygen and nitrogen. The cleaning method is: vacuum to 10 -1 Pa, and then filled with high-purity argon to make the pressure in the chamber at 0.05MPa.

[0053] Step 3: Start the arc to melt the zirconium ingot in one of the crucibles, in order to remove oxygen again and reduce impurities.

[0054] Step 4: After the above step 3 is completed, adjust the current to melt the copper and titanium blocks in the crucible, and at the same time turn on the magnetic stirring device to make the two mix more even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com