Method for preparing calcium sulfate whiskers with oyster shells

A calcium sulfate whisker and oyster shell technology, applied in the field of calcium sulfate whisker preparation, can solve the problems of undesired crystal form, general product quality, high energy consumption and high cost, and achieve large aspect ratio and control effect Excellent, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

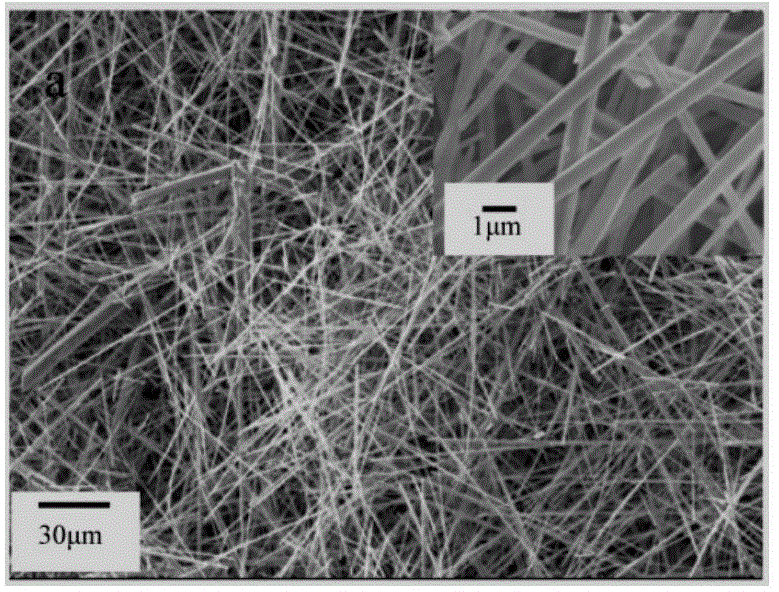

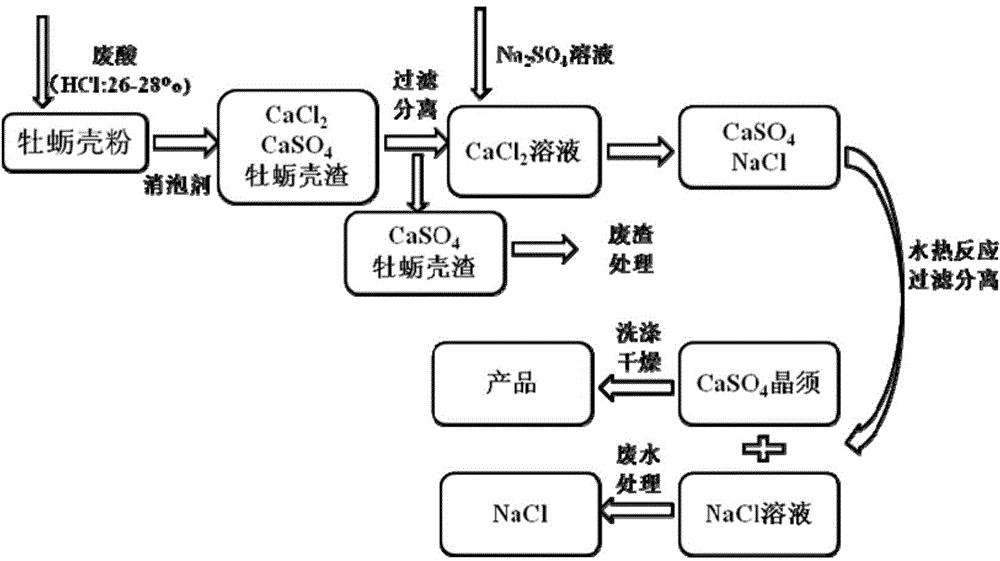

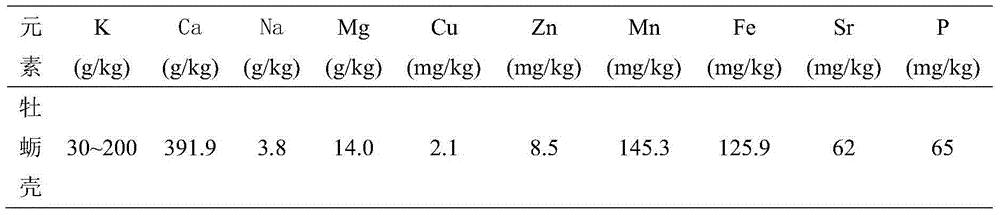

[0036] The oyster shells are soaked in dilute hydrochloric acid, washed and dried, and the dried oyster shells are crushed into powder by a high-speed universal grinder for later use. The prepared oyster shell powder was reacted with industrial waste hydrochloric acid to prepare a calcium chloride solution with a concentration of 2.2 mol / L. At a temperature of 60°C, add a sodium sulfate solution with a concentration of 0.1 to 3.0 mol / L into the prepared calcium chloride solution while stirring, and continue to react for 60 minutes after the addition is complete to obtain a calcium sulfate material with a concentration of 20%. pulp. Put the slurry into a hydrothermal reaction kettle, and conduct hydrothermal treatment at a temperature of 150° C. for 5 hours. Filter the suspension after the hydrothermal reaction, and dry the obtained product at 100°C for 8 hours to obtain calcium sulfate hemihydrate whiskers with an average length of 120 μm and an average diameter of 0.5 μm. Th...

Embodiment 2

[0038] The oyster shells are soaked in dilute hydrochloric acid, washed and dried, and the dried oyster shells are crushed into powder by a high-speed universal grinder for later use. The prepared oyster shell powder was reacted with industrial waste hydrochloric acid to prepare a calcium chloride solution with a concentration of 2.4mol / L. At a temperature of 55°C, add a sodium sulfate solution with a concentration of 0.1 to 3.0 mol / L into the prepared calcium chloride solution while stirring, and continue the reaction for 55 minutes after the addition is complete to obtain a calcium sulfate material with a concentration of 22%. pulp. The slurry was put into a hydrothermal reactor, and hydrothermally treated at a temperature of 185° C. for 6 hours. Filter the suspension after the hydrothermal reaction, and dry the obtained product at 100°C for 7 hours to obtain calcium sulfate hemihydrate whiskers with an average length of 150 μm and an average diameter of 0.7 μm. The product...

Embodiment 3

[0040]The oyster shells are soaked in dilute hydrochloric acid, washed and dried, and the dried oyster shells are crushed into powder by a high-speed universal grinder for later use. The prepared oyster shell powder was reacted with industrial waste hydrochloric acid to prepare a calcium chloride solution with a concentration of 2.9 mol / L. At a temperature of 75°C, add a sodium sulfate solution with a concentration of 0.1 to 3.0 mol / L into the prepared calcium chloride solution while stirring, and continue the reaction for 80 minutes after the addition is complete to obtain a calcium sulfate material with a concentration of 26%. pulp. The slurry was put into a hydrothermal reaction kettle, and hydrothermally treated at a temperature of 145° C. for 4 hours. Filter the suspension after the hydrothermal reaction, and dry the obtained product at 100°C for 5 hours to obtain calcium sulfate hemihydrate whiskers with an average length of 180 μm and an average diameter of 1.6 μm. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com