Nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, batteries, etc., can solve the problems of battery safety reduction, thermal instability, battery heating, etc., and achieve the goal of suppressing the increase of internal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

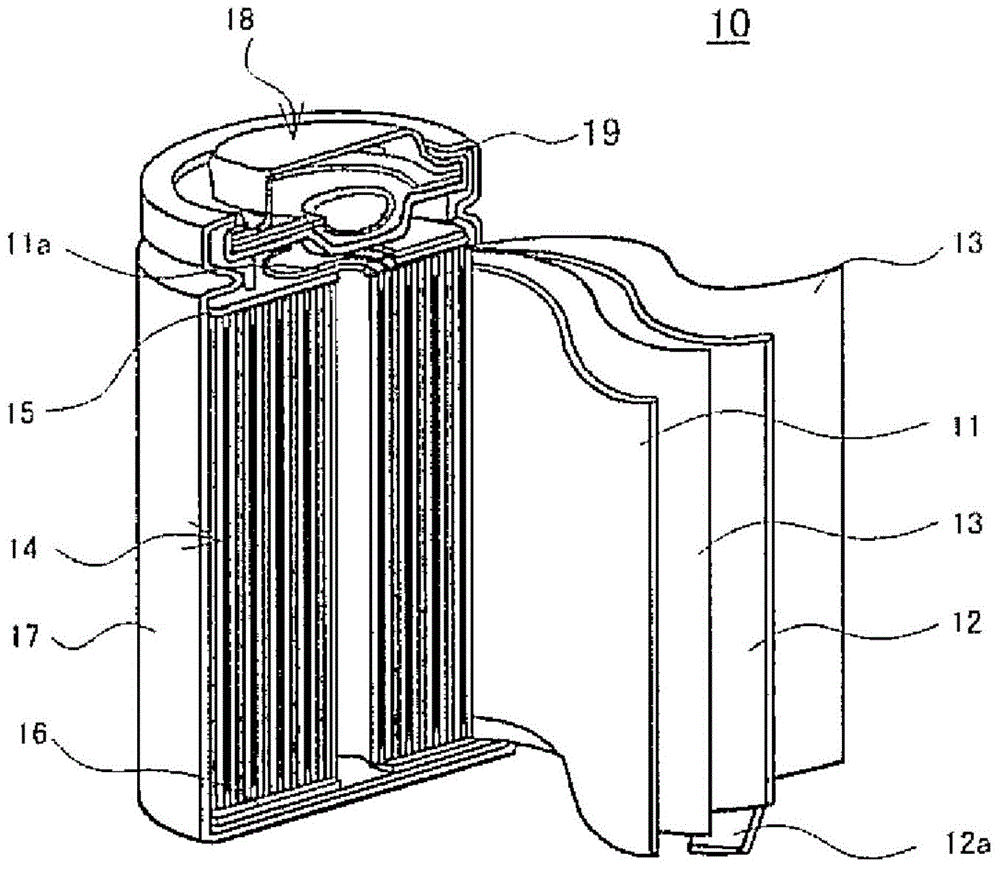

Image

Examples

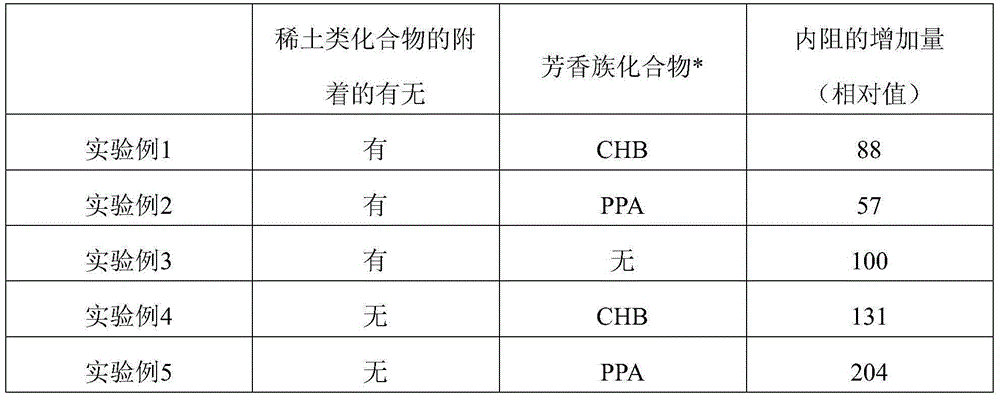

experiment example 1

[0021] A specific method of manufacturing the nonaqueous electrolyte secondary battery of Experimental Example 1 of the present invention will be described below.

[0022] 〔Production of positive electrode plate〕

[0023] Li 2 CO 3 and [Ni 0.35 mn 0.30 co 0.35 ](OH) 2 Mixed and then obtained by heating at 900 °C from Li 1.06 Ni 0.33 mn 0.28 co 0.33 o 2 The lithium nickel cobalt manganese composite oxide shown. 1000 g of the lithium-nickel-cobalt-manganese composite oxide particles were poured into 3 liters of pure water and stirred. Next, a solution in which 4.58 g of erbium nitrate pentahydrate was dissolved was added thereto. At this time, an appropriate amount of 10 mass % sodium hydroxide aqueous solution was added to adjust the pH of the solution containing the lithium nickel cobalt manganese composite oxide to 9. Next, after suction filtration and water washing, the powder obtained after heat treatment at 300° C. for 5 hours in the air was dried to obtain a ...

experiment example 2

[0032] In Experimental Example 2, for the nonaqueous electrolytic solution of Experimental Example 1, instead of CHB, 3-phenylpropyl acetate (PPA) was added as an aromatic compound, and the nonaqueous electrolytic solution was produced in the same manner as in Experimental Example 1 except that liquid. In addition, a potential sweep test was performed in the same manner as in Experimental Example 1, and it was confirmed that the oxidation decomposition potential of PPA was about 4.8Vvs.Li / Li + . Moreover, the nonaqueous electrolyte secondary battery of Experimental Example 2 was produced similarly to Experimental Example 1 except having used the said electrolytic solution.

experiment example 3

[0034] In Experimental Example 3, a nonaqueous electrolyte secondary battery of Experimental Example 3 was produced in the same manner as in Experimental Example 1 except that no aromatic compound was added to the nonaqueous electrolyte solution of Experimental Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com