Shell powder, preparation method thereof, modification method thereof and application thereof

A technology of shell powder and shell powder, applied in the direction of botanical equipment and methods, applications, chemicals for biological control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

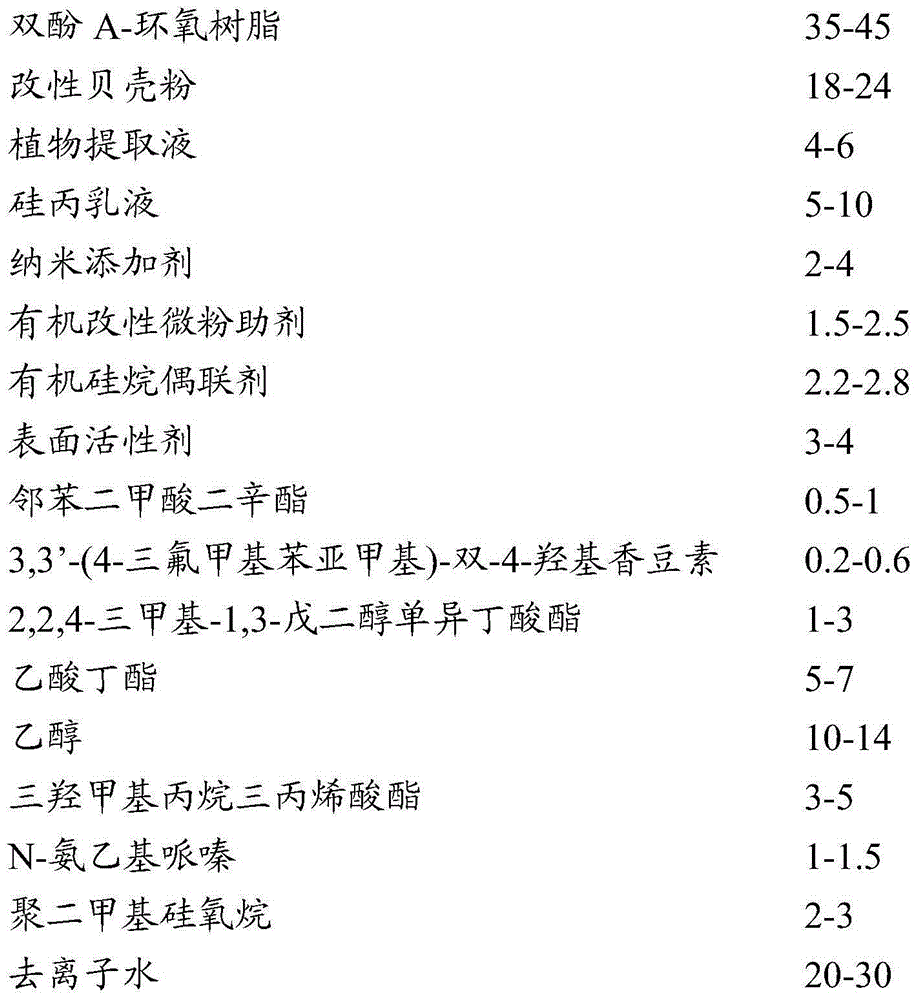

Examples

preparation example 0

[0102] Preparation Example 0: Preparation of Shell Powder

[0103] (1) The washed shells are sequentially calcined in a three-stage gradient, and the specific calcination operation is as follows:

[0104] A1: Calcining at 400°C for 12 minutes;

[0105] A2: Raise the temperature to 500°C at a heating rate of 10°C / min, and keep the temperature for calcination for 22 minutes;

[0106] A3: Raise the temperature to 700°C at a heating rate of 5°C / min, and keep it for calcination at this temperature for 35 minutes. After the calcination is completed, cool it down to room temperature naturally to obtain the calcined shell;

[0107] (2) Pulverize and grind the calcined shells, and pass through a 300-mesh sieve to obtain the shell powder, which is named as BKF.

preparation example 1

[0108] Preparation Example 1: Preparation of Modified Shell Powder

[0109] B1: Obtain shell powder BKF according to the same method as above-mentioned preparation example 0, namely implement the following steps:

[0110] (1) The washed shells are sequentially calcined in a three-stage gradient, and the specific calcination operation is as follows:

[0111] A1: Calcining at 400°C for 12 minutes;

[0112] A2: Raise the temperature to 500°C at a heating rate of 10°C / min, and keep the temperature for calcination for 22 minutes;

[0113] A3: Raise the temperature to 700°C at a heating rate of 5°C / min, and keep it for calcination at this temperature for 35 minutes. After the calcination is completed, cool it down to room temperature naturally to obtain the calcined shell;

[0114] (2) crushing and grinding the calcined shells, and passing through a 300-mesh sieve to obtain the shell powder;

[0115] B2: Add diethanolamine and absolute ethanol to n-butyl titanate (wherein the mol...

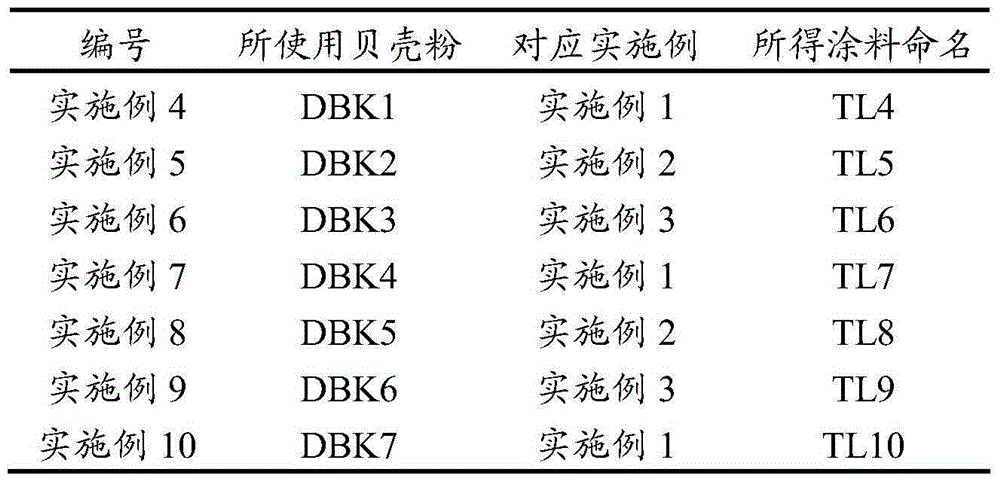

preparation example 11-17

[0117] Preparation Example 1.1-1.7: Preparation of Modified Shell Powder

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com