Hydrogen peroxide low-temperature vaporization sterilization device and method

A hydrogen peroxide and sterilization device technology, which is applied in the field of hydrogen peroxide low-temperature vaporization sterilization device, can solve the problems of complex control system of the device, long disinfection and sterilization cycle, and reduced sterilization efficiency, and achieve good air mass diffusivity, Effect of small increase in temperature and relative humidity and reduced corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

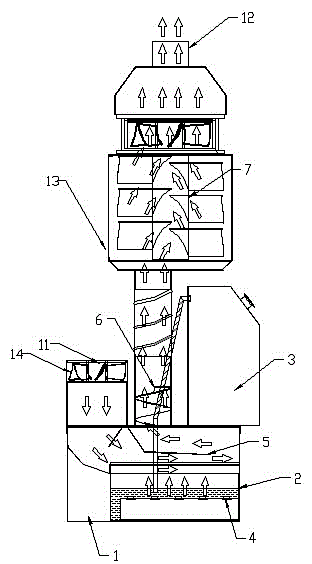

[0021] see figure 1 As shown, a hydrogen peroxide low-temperature vaporization sterilization device includes a main box body 1, and a hydrogen peroxide supply device is arranged in the main box body 1, and the hydrogen peroxide supply device includes a The hydrogen peroxide vaporization tank 2 inside 1 and the hydrogen peroxide liquid storage bottle 3 arranged outside the main box body 1 use the principle of the connector to make the hydrogen peroxide liquid storage bottle 3 flow to the hydrogen peroxide vaporization tank inside the main box body 1 2. Replenish hydrogen peroxide in real time and keep the liquid level constant to ensure the constant vaporization rate; the hydrogen peroxide vaporization tank of the hydrogen peroxide supply device is provided with a blasting water column device, and the blasting water column device is a high High-frequency resonant vibrating piece 4, high-frequency resonant vibrating piece 4 makes the hydrogen peroxide solution produce a 1-20 μm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com