MoFs adsorbent and application thereof

An adsorbent and adsorption tower technology, applied in the field of new porous adsorption materials, can solve the problems of limited separation capacity and low adsorption capacity of n-isoparaffin mixture, and achieve improved adsorption separation performance, increase adsorption capacity, and reduce desorption temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

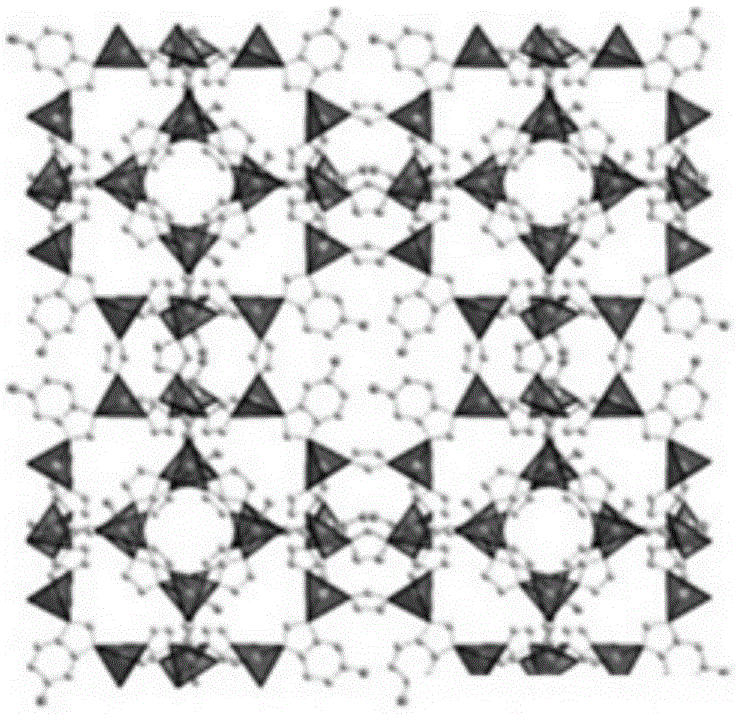

[0025] With 100gZIF-76 powder (its cage-like skeleton structure is as figure 1 Shown), 5g of kaolin and 3g of fennel powder were mixed well, slowly added 30g of water and kneaded evenly, extruded into strips, dried at 80°C, and calcined at 200°C for 3h to obtain shaped ZIF-76 adsorbent. Fill the shaped ZIF-76 adsorbent in the adsorption tower, use the alkane mixture with n-heptane content of 95% as the raw material for adsorption and separation, and the remaining components in the mixture are C6 and C7 isoparaffins. After the alkane mixture is vaporized at 120°C, in 35h -1 The space velocity enters the adsorption tower, the adsorption temperature is 150°C, and the adsorption pressure is 0.1MPa in gauge pressure. After the adsorption is completed, carbon dioxide gas is used to purge and desorb. The preheating temperature of the purge gas is 120°C and the space velocity is 600h. -1 , The desorption temperature of the adsorption tower is 120°C, and the desorption pressure is 0....

Embodiment 2

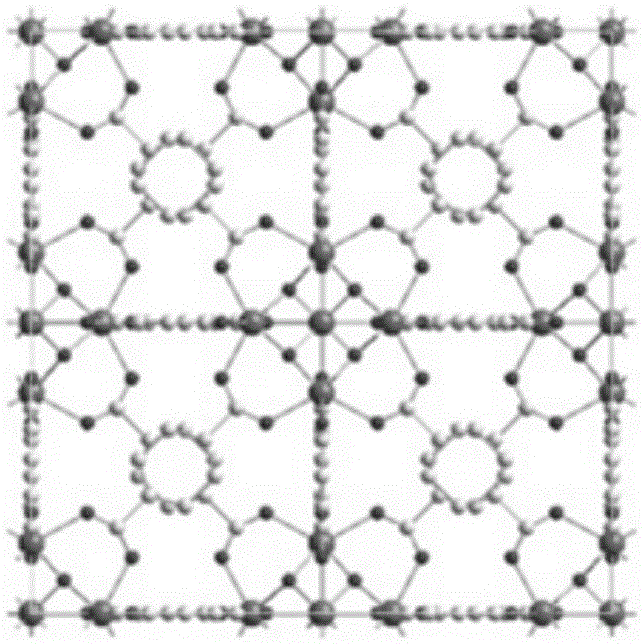

[0027] With 100gUiO-66 powder (its cage-like skeleton structure is as figure 2 shown), 50g of pseudo-boehmite and 60g of carboxymethyl cellulose were mixed well, slowly added 20g of distilled water and kneaded evenly, extruded into strips, dried at 100°C, and roasted at 350°C for 0.5h to obtain a shaped UiO-66 adsorbent. Fill the formed UiO-66 adsorbent in the adsorption column, use the alkane mixture with n-hexane content of 80% as the raw material for adsorption and separation, and the remaining components in the mixture are C5 and C6 isoparaffins. After the alkane mixture is vaporized at 100°C, it takes 480h -1 The space velocity enters the adsorption tower, the adsorption temperature is 280°C, and the adsorption pressure is 1.5MPa in gauge pressure. After the adsorption is completed, nitrogen purging is used for desorption, the preheating temperature of the purging gas is 220°C, and the space velocity is 50h -1 , The desorption temperature of the adsorption tower is 30...

Embodiment 3

[0029] According to the method and steps described in Example 2, 20g of polyethylene glycol and 30g of pseudoboehmite were added to the binder to obtain a shaped UiO-66 adsorbent, and the shaped UiO-66 adsorbent was applied to a compound containing 85% n-hexane The alkane mixture is separated, the adsorption and desorption pressures are both 0 MPa, and the purity of n-hexane is above 99% within 2 to 45 minutes of adsorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com