Preparation method for silicon-aluminium composite oxide with controllable pore structure

A composite oxide and pore structure technology, which is applied in chemical instruments and methods, chemical/physical processes, catalyst supports, etc., can solve the problems of small pore size, uneven distribution of silicon and aluminum, and non-concentrated pore size distribution to achieve high selectivity , suitable activity, effective ingredients to improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

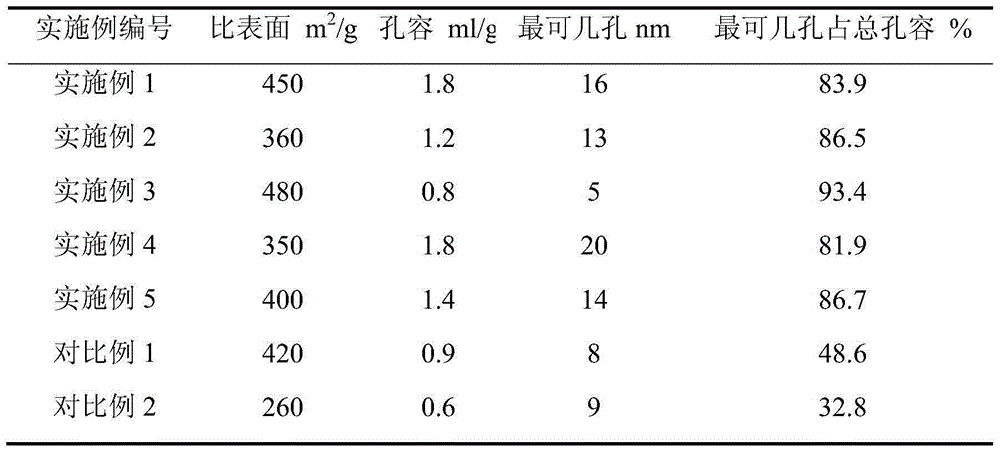

Examples

Embodiment 1

[0025] Take SiO 2 Put 1.5L of water glass solution with a content of 55-150g / L in the glue tank, add Al at a certain flow rate 2 o 3 The aluminum sulfate solution with a content of 50-90g / L stops feeding until the pH value is 8.0-9.0. After the gelation is completed, put the above slurry into the autoclave, raise the temperature to 120°C, and keep it for 2h. After the reaction, separate the solid from the liquid and wash , to obtain a product filter cake from which impurities are removed, the filter cake is dried and pulverized to obtain a silicon-aluminum composite oxide powder.

Embodiment 2

[0027] Take SiO 2 Put 1.5L of acidic silica sol solution with a content of 55-150g / L in the gel-forming tank, and add Al at a certain flow rate 2 o 3 The sodium metaaluminate solution with a content of 50-90g / L stops feeding until the pH value is 7.0-8.0. After the gelation is completed, put the above slurry into the autoclave, raise the temperature to 140°C, and keep it for 2h. After the reaction is finished, the solid-liquid is separated and washed to obtain a product filter cake from which impurities are removed. The filter cake is dried and pulverized to obtain a silicon-aluminum composite oxide powder.

Embodiment 3

[0029] Take SiO 2 Put 1.5L of alkaline silica sol solution with a content of 55-150g / L in the gel-forming tank, and add Al at a certain flow rate 2 o 3 The aluminum sulfate solution with a content of 50-90g / L stops feeding until the pH value is 6.0-7.0. After the gelation is completed, put the above slurry into the autoclave, raise the temperature to 160°C, and keep it for 10h. After the reaction is finished, the solid-liquid is separated and washed to obtain a product filter cake from which impurities are removed. The filter cake is dried and pulverized to obtain a silicon-aluminum composite oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com