Visible light responsive NaFeTi3O8 photocatalytic material, preparation method and application thereof

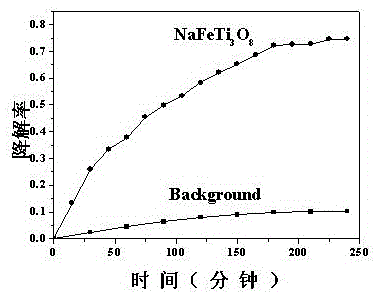

A photocatalytic material, sodium iron titanate technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, physical/chemical process catalysts, etc., can solve problems that are insufficient to guide large-scale industrial applications, quantum conversion problems such as low efficiency and low solar energy utilization, to achieve the effects of easy industrial production, low cost, and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

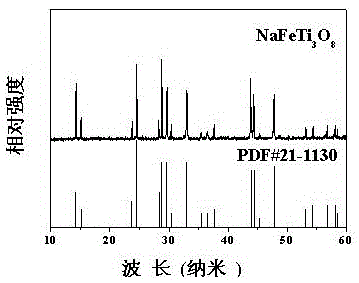

[0042] Preparation of NaFeTi by High Temperature Solid Phase Method 3 o 8 , That is, mix various oxides or carbonates as raw materials according to the target composition stoichiometric ratio, and then synthesize them in an air atmosphere under normal pressure.

[0043] According to the chemical formula NaFeTi 3 o 8 , respectively weighed sodium oxide Na 2 O: 0.62 g, Fe3O4 3 o 4 : 1.54 g, Titanium Dioxide TiO 2 : 4.79 grams, grind the raw materials in an agate mortar and mix them evenly, then perform the first calcination, the calcination temperature is 250°C, the calcination time is 5 hours, the atmosphere is air atmosphere, the sample is taken out and cooled naturally; the first calcined sample After grinding evenly, carry out the second calcination, the calcination temperature is 600°C, the calcination time is 10 hours, the atmosphere is air atmosphere, take out the sample and cool naturally; after the sample is ground evenly, carry out the third calcination in the ai...

Embodiment 2

[0050] Preparation of NaFeTi by High Temperature Solid Phase Method 3 o 8 , according to the chemical formula NaFeTi 3 o 8 , respectively weighed sodium carbonate Na 2 CO 3 : 1.06 g, Fe2O3 2 o 3 : 1.60 g, titanium dioxide TiO 2 : 4.79 grams, grind the raw materials in an agate mortar and mix them evenly, then perform the first calcining, the calcining temperature is 500°C, the calcining time is 2 hours, the atmosphere is air atmosphere, the sample is taken out and cooled naturally; the first calcined sample After grinding evenly, carry out the second calcination, the calcination temperature is 950°C, the calcination time is 17 hours, the atmosphere is air atmosphere, take out the sample and cool naturally; after the sample is ground evenly, carry out the third calcination in the air atmosphere, the calcination temperature is 1300°C , the calcination time is 12 hours, and NaFeTi is obtained 3 o 8 powder.

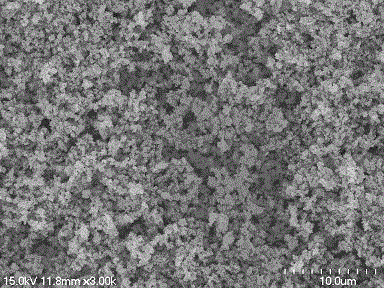

[0051] After observation, the NaFeTi prepared in Example 2 3 ...

Embodiment 3

[0053] Preparation of NaFeTi 3 o 8

[0054] Preparation of NaFeTi by High Temperature Solid Phase Method 3 o 8 , respectively weighed sodium chloride NaCl: 1.17 grams, ferric chloride FeCl 3 : 3.24 g, Titanium Dioxide TiO 2 : 4.79 grams, the raw materials are ground in an agate mortar and mixed evenly, and then calcined for the first time, the calcining temperature is 400 ° C, the calcining time is 6 hours, the atmosphere is air atmosphere, the sample is taken out and cooled naturally; the sample calcined for the first time After uniform grinding, the second calcination is carried out, the calcination temperature is 850°C, the calcination time is 8 hours, the atmosphere is air atmosphere, the sample is taken out and cooled naturally; after the sample is evenly ground, the third calcination is carried out in the air atmosphere, the calcination temperature is 1200°C , the calcination time is 18 hours, and the photocatalyst sodium ferric titanate NaFeTi is obtained 3 o 8 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com