Photocatalyst responsive to ultraviolet light and visible light and preparation method thereof

A photocatalyst and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low photon quantum efficiency, refractory quantity, and sunlight utilization rate Low-level problems, to achieve the effect of strong photocatalytic activity, environmental friendliness, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

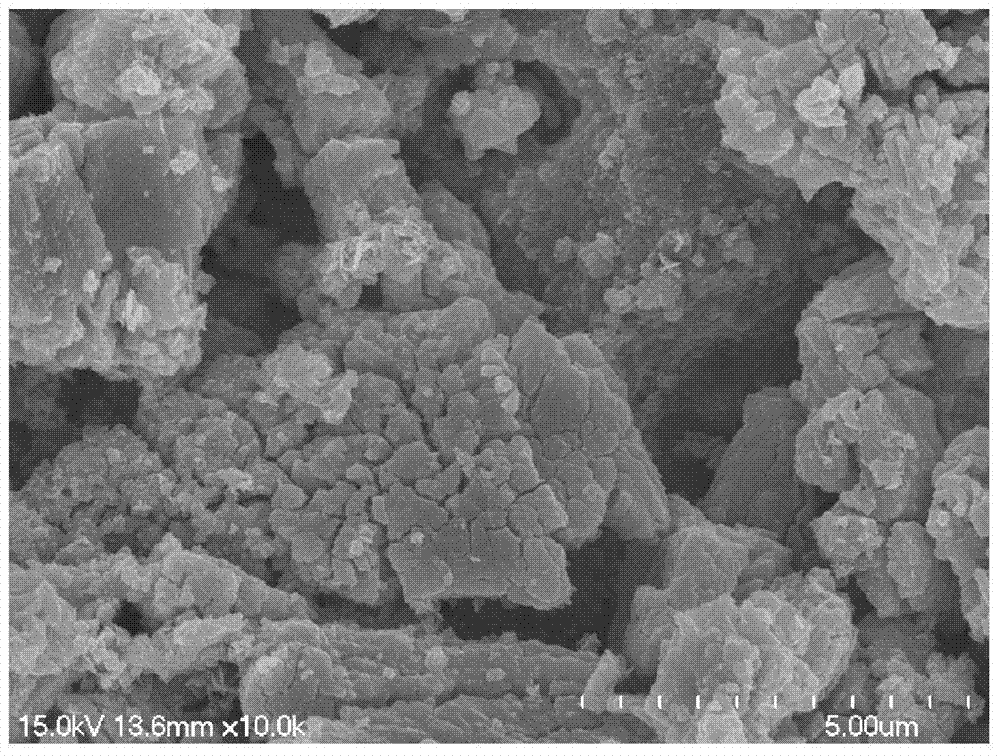

[0050] Preparation of Nd 5 FeTi 4 o 17 , according to the chemical formula Nd 5 FeTi 4 o 17 , respectively weigh neodymium oxide Nd 2 o 3 : 3.365 g, Fe2O3 2 o 3 : 0.320 g, titanium dioxide TiO 2 : 1.278g, after grinding and mixing the raw materials in an agate mortar, calcining for the first time in air atmosphere, the temperature of the first calcining is 400°C, the calcining time is 15 hours, after natural cooling, take out the sample, grind and mix uniformly Carry out the second calcination in the air atmosphere, the second calcination temperature is 900 ℃, the calcination time is 15 hours, after natural cooling, take out the sample, grind and mix evenly; carry out the final calcination under the air atmosphere, the final calcination temperature is 1250 ℃, the calcination time is 15 hours, and the photocatalyst powder is obtained.

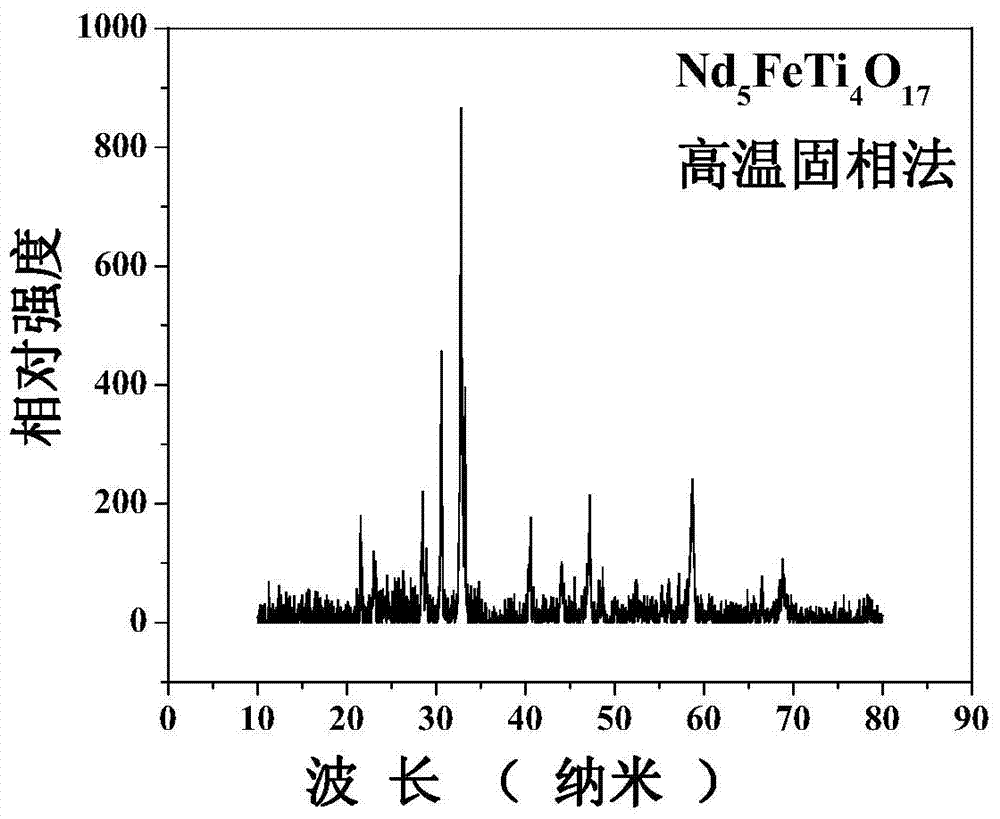

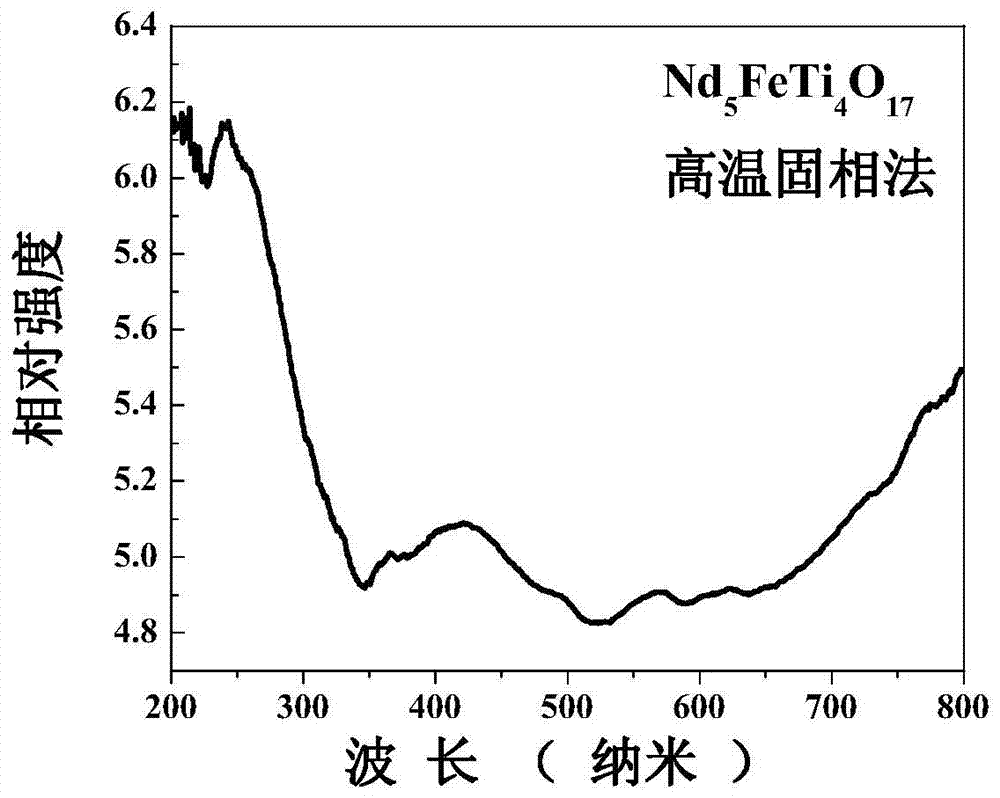

[0051] See attached figure 1 , it is the X-ray powder diffraction spectrum of the sample prepared according to the technical scheme ...

Embodiment 2

[0057] Preparation of Nd 5 FeTi 4 o 17 , according to the chemical formula Nd 5 FeTi 4 o 17 , respectively weigh neodymium carbonate Nd 2 (CO 3 )·H 2 O: 4.865 grams, ferric oxide Fe 3 o 4 : 0.309 g, titanium dioxide TiO 2 : 1.278g, after grinding and mixing the raw materials in an agate mortar, select the air atmosphere for the first calcination, the temperature for the first calcination is 300°C, and the calcination time is 16 hours. Carry out the second calcination in the air atmosphere, the second calcination temperature is 800 ℃, the calcination time is 16 hours, after natural cooling, take out the sample, grind and mix evenly; carry out the final calcination in the air atmosphere, the final calcination temperature is 1200 ℃, the calcination time is 16 hours, and the photocatalyst Nd is obtained 5 FeTi 4 o 17 powder.

[0058] The sample prepared in this embodiment, its main structural morphology, ultraviolet-visible diffuse reflectance spectrum, degradation r...

Embodiment 3

[0060] Preparation of Nd 5 FeTi 4 o 17 , according to the chemical formula Nd 5 FeTi 4 o 17 , respectively weigh neodymium chloride NdCl 3 : 5.012 g, iron hydroxide Fe(OH) 3 : 0.427 g, titanium dioxide TiO 2 : 1.278g, after grinding and mixing the raw materials in an agate mortar, select the air atmosphere for the first calcination, the first calcination temperature is 800°C, the calcination time is 3 hours, after natural cooling, take out the sample, grind and mix evenly Carry out the second calcination under the air atmosphere, the second calcination temperature is 1100 ℃, the calcination time is 6 hours, after natural cooling, take out the sample, grind and mix evenly; carry out the final calcination under the air atmosphere, the final calcination temperature is 1300 ℃, The calcination time is 6 hours, and the photocatalyst Nd is obtained 5 FeTi 4 o 17 powder.

[0061] The sample prepared in this embodiment, its main structural morphology, ultraviolet-visible dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com