Preparation method of regulable basic cupric carbonate micro-nano hierarchical structure

A hierarchical structure, copper carbonate technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of uncontrollable structure, inability to have both nanostructure and microstructure, cumbersome preparation methods and processes, etc., and achieve green The effect of energy consumption, simple method and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

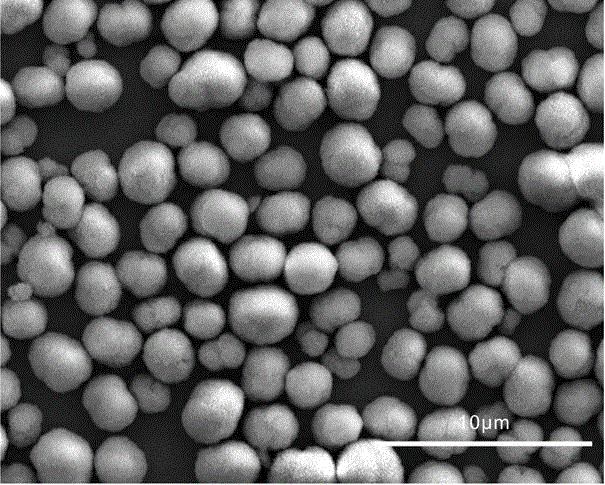

[0030] A kind of adjustable basic copper carbonate (Cu 2 (OH) 2 CO 3 ) The preparation method of micro-nano hierarchical structure includes the following steps:

[0031] (1) Under the action of magnetic stirring, add 1.2mmol copper acetate monohydrate (Cu(Ac) 2 ·H 2 O) Dissolve in an Erlenmeyer flask containing 30 mL of deionized water to form a blue transparent solution A;

[0032] (2) Under the action of magnetic stirring, put 1.4mmolNa 2 CO 3 Dissolve in a beaker containing 20 mL of deionized water to form a clear transparent colorless solution B;

[0033] (3) Under the action of magnetic stirring, quickly pour solution B into solution A, and continue stirring for 10 minutes to form mixed solution C;

[0034] (4) Seal the solution C in an Erlenmeyer flask, stand for 24 hours at room temperature, take out the precipitated product, and wash it with deionized water and absolute ethanol 3 times each to obtain a green solid powder;

[0035] (5) Dry the above-mentioned green solid powder i...

Embodiment 2

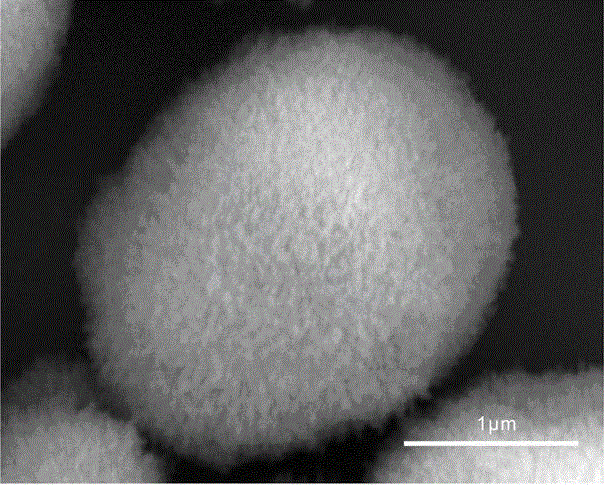

[0038] A kind of adjustable basic copper carbonate (Cu 2 (OH) 2 CO 3 ) The preparation method of micro-nano hierarchical structure includes the following steps:

[0039] (1) Under the action of magnetic stirring, add 1.2mmol copper acetate monohydrate (Cu(Ac) 2 ·H 2 O) Dissolve in an Erlenmeyer flask containing 30 mL of deionized water to form a blue transparent solution A;

[0040] (2) Under the action of magnetic stirring, put 1.4mmolK 2 CO 3 Dissolve in a beaker containing 20 mL of deionized water to form a clear transparent colorless solution B;

[0041] (3) Under the action of magnetic stirring, quickly pour solution B into solution A, and continue stirring for 10 minutes to form mixed solution C;

[0042] (4) Seal the solution C in an Erlenmeyer flask, stand for 24 hours at room temperature, take out the precipitated product, and wash it with deionized water and absolute ethanol 3 times each to obtain a green solid powder;

[0043] (5) Dry the above-mentioned green solid powder in...

Embodiment 3

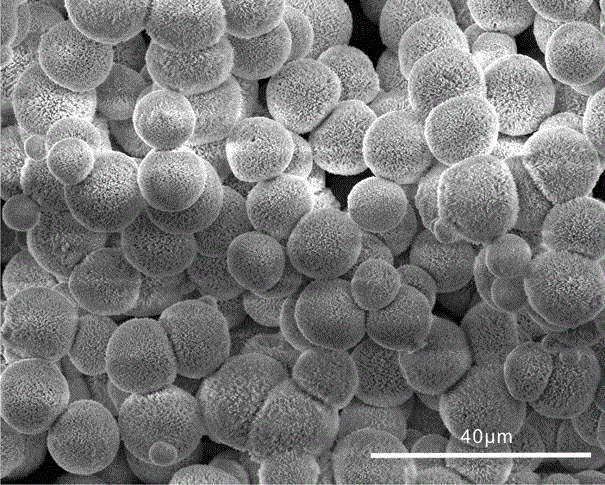

[0046] A kind of adjustable basic copper carbonate (Cu 2 (OH) 2 CO 3 ) The preparation method of micro-nano hierarchical structure includes the following steps:

[0047] (1) Under the action of magnetic stirring, add 1.2mmol copper chloride dihydrate (CuCl 2 ·2H 2 O) Dissolve in an Erlenmeyer flask containing 30 mL of deionized water to form a blue transparent solution A;

[0048] (2) Under the action of magnetic stirring, put 1.4mmolNa 2 CO 3 Dissolve in a beaker containing 20 mL of deionized water to form a clear transparent colorless solution B;

[0049] (3) Under the action of magnetic stirring, quickly pour solution B into solution A, and continue stirring for 10 minutes to form mixed solution C;

[0050] (4) Seal the solution C in an Erlenmeyer flask, stand for 24 hours at room temperature, take out the precipitated product, and wash it with deionized water and absolute ethanol 3 times each to obtain a green solid powder;

[0051] (5) Dry the above-mentioned green solid powder in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com