Industrial circulating water fish farming denitrification zero emission system

A technology for fish farming and circulating water, applied in fish farming, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of slow growth of vegetables, low efficiency, insufficient nutrition, etc., and achieves the elimination of ozone disinfection. The effect of the process and the high-efficiency process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

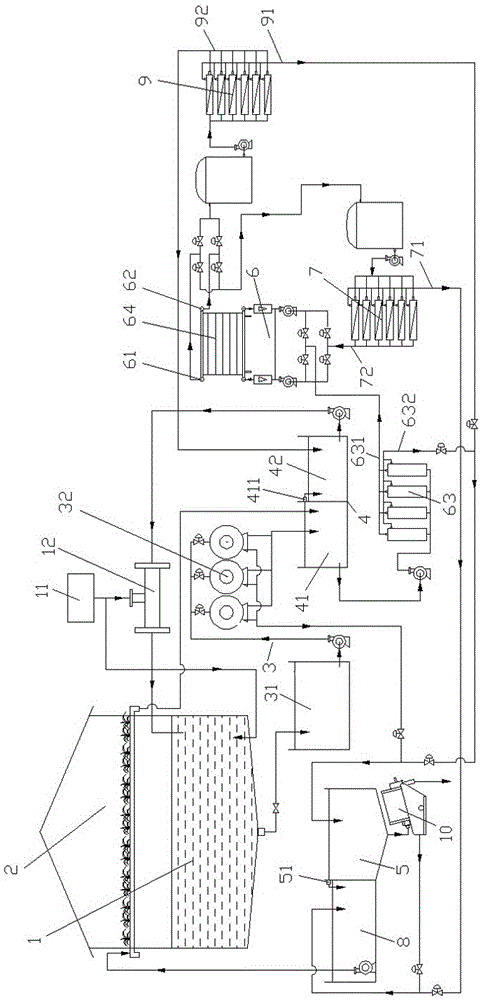

[0020] Such as figure 1 As shown, a factory-like circulating water fish culture denitrification and zero-emission system includes a culture pond 1 for high-density fish culture, and a PVC pipe-type soilless culture plant planting structure 2 is built above the culture pond 1, The culture pond 1 is connected to a preliminary filter device 3, one of the preliminary filter devices 3 is connected to the regulating pool 4, and the other path of the preliminary filter device 3 is connected to the sludge pond 5, and the treatment front end 41 of the regulating pool 4 is Connected to the electromigration device 6, the basic end 61 of the electromigration device 6 is connected to the front-end membrane concentration device 7, and the high-concentration end 71 of the front-end membrane concentration device 7 is connected to the plant culture solution storage tank 8, and the front end The low concentration end 72 of the membrane concentration device 7 returns to the acid end 62 of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com