Conjugated microporous polymer adopting ketone-enamine bond connection and preparation method thereof

A technology of conjugated polymers and conjugated micropores, applied in the field of conjugated microporous polymers, can solve the problems of high equipment requirements, high cost, and porous materials that cannot meet the needs, and achieve high specific surface area and high stability , equipment requirements simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

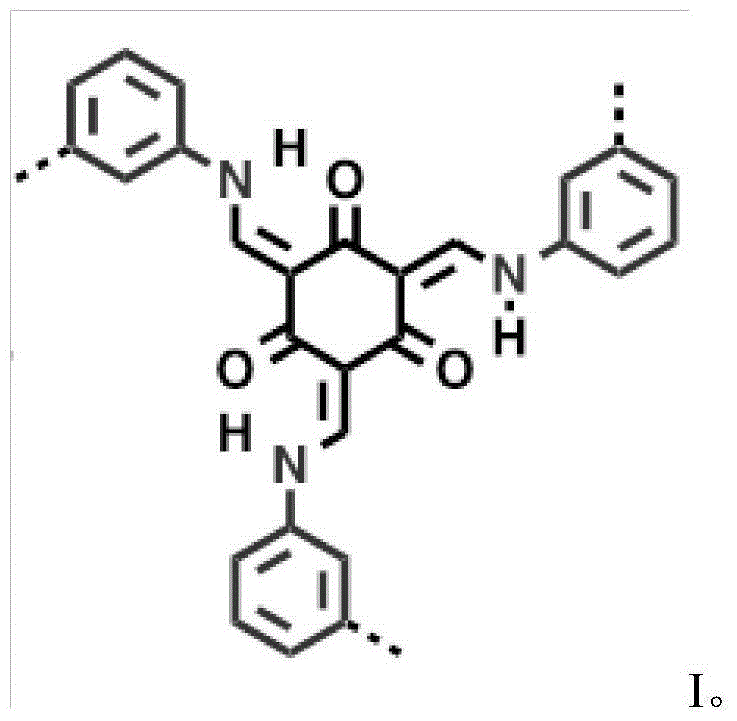

[0021] This embodiment provides a method for preparing a conjugated microporous polymer linked by ketone-enamine bonds, the steps are as follows:

[0022] Step 1, get 189mg of 2,4,6-trialdehyde phloroglucinol (C 9 h 6 o 6 ), 3mL of 3mol / L acetic acid, add 20ml of N,N-dimethylformamide, put it into a 50ml reaction bottle, and stir for 5 minutes under anaerobic conditions;

[0023] Step 2, get the m-phenylenediamine of 144mg (C 6 h 8 N 2 ) into a reaction flask, reacted at a temperature of 150° C. for 72 hours under anaerobic conditions, and filtered to obtain crude product A;

[0024] In step 3, the crude product A was successively washed three times with 30 ml of N,N-dimethylformamide, 30 ml of tetrahydrofuran and 30 ml of anhydrous acetone, and dried to obtain a conjugated microporous polymer linked by ketone-enamine bonds.

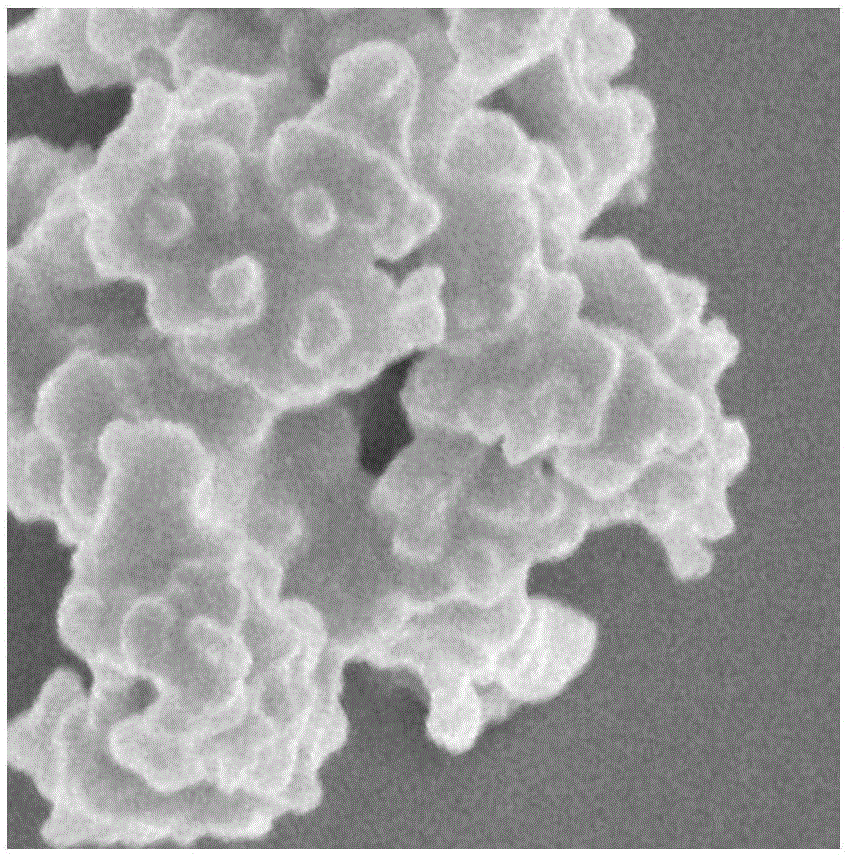

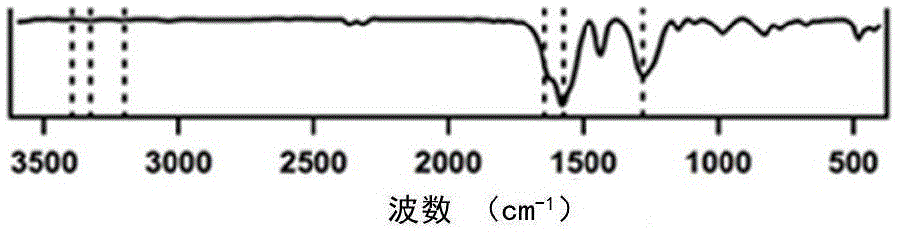

[0025] Implementation effect, the electron micrograph of the conjugated microporous polymer that the ketoenamine linkage of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com