Flame retardant coating composition

A technology for flame retardant coatings and compositions, applied in the field of coatings, can solve the problems of unsatisfactory rapid curing performance of flame retardant coating compositions, reduced environmental protection of water-based coatings, poor flame retardant effect of flame retardants, etc., and achieves excellent application value, The effect of low cost and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

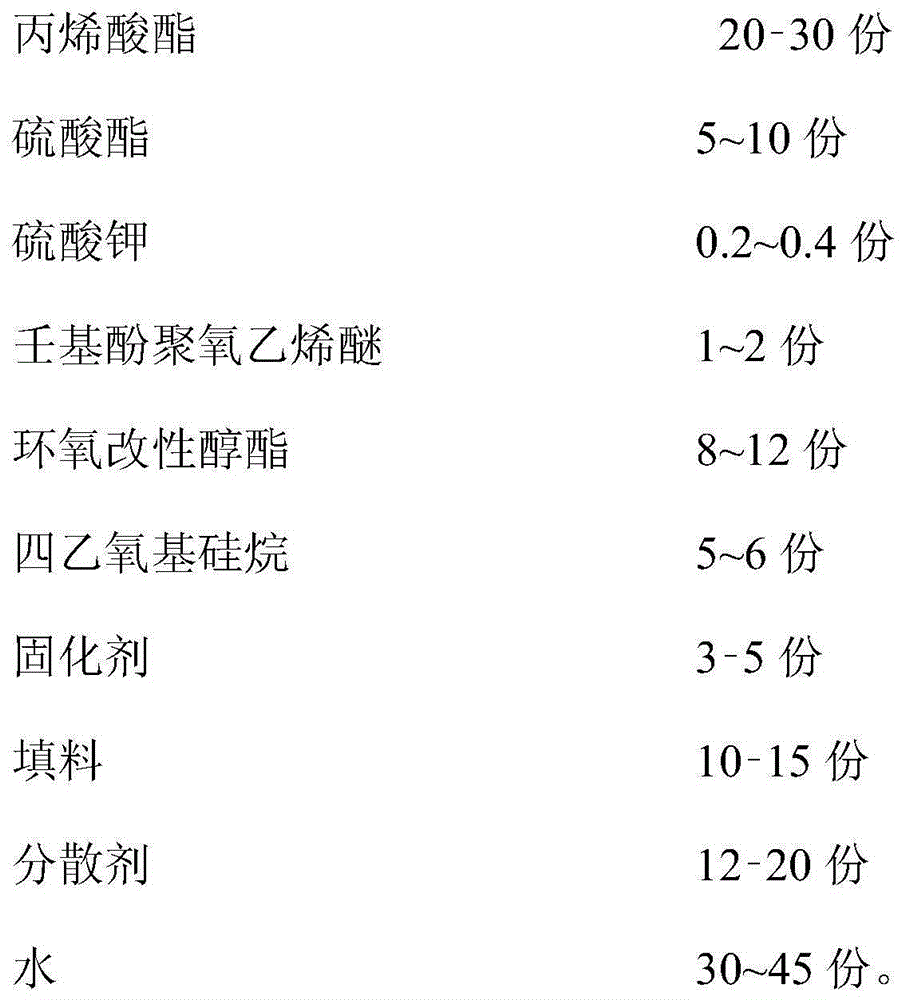

Method used

Image

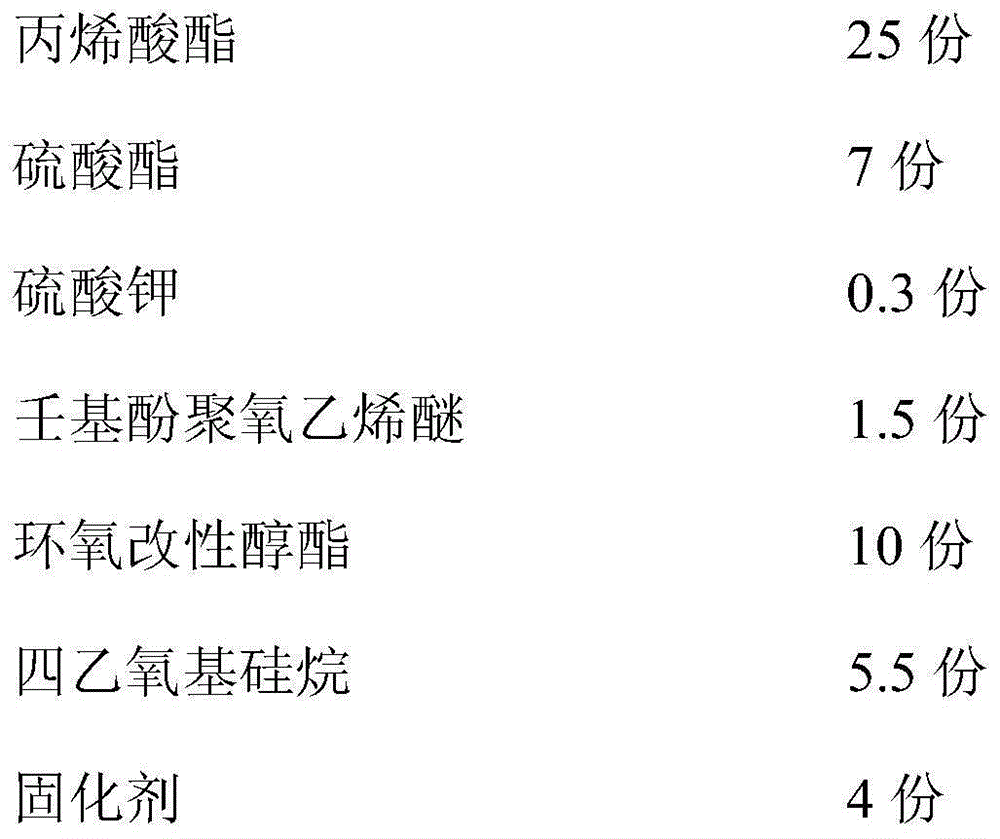

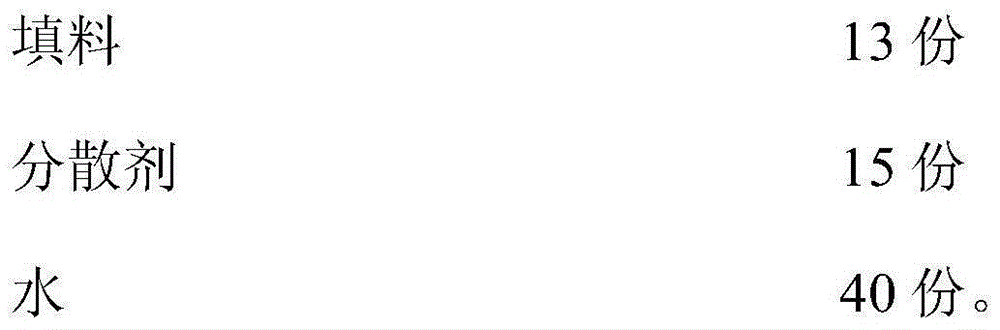

Examples

Embodiment 1

[0048] Embodiment 1: the preparation of epoxy modified alcohol ester

[0049] The ratio of raw materials used is as follows:

[0050] 0.7 parts of bisphenol A epoxy resin

[0051] 1.2 parts of maleic anhydride

[0052] 13 parts of ethylene glycol

[0053] In a nitrogen atmosphere, weigh the raw materials according to the above ratio and add them to the reactor, react at 110°C for 55 minutes, then add 8 drops of hydrochloric acid dropwise, and continue the reaction for 12 minutes to obtain epoxy-modified alcohol ester.

Embodiment 2

[0054] Embodiment 2: the preparation of epoxy modified alcohol ester

[0055] The ratio of raw materials used is as follows:

[0056] Bisphenol A epoxy resin 0.5 parts

[0057] 1 part maleic anhydride

[0058] 10 parts of ethylene glycol

[0059] In an argon atmosphere, weigh the raw materials according to the above ratio and add them to the reactor, react at 100°C for 50 minutes, then add 5 drops of hydrochloric acid dropwise, and continue the reaction for 10 minutes to obtain epoxy-modified alcohol ester.

Embodiment 3

[0061] Preparation of Epoxy Modified Alcohol Esters

[0062] The ratio of raw materials used is as follows:

[0063] 0.8 parts of bisphenol A epoxy resin

[0064] Maleic anhydride 1.5 parts

[0065] 15 parts of ethylene glycol

[0066] In an argon atmosphere, weigh the raw materials according to the above ratio and add them to the reactor, react at 120°C for 60 minutes, then add 10 drops of hydrochloric acid dropwise, and continue the reaction for 15 minutes to obtain epoxy-modified alcohol ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com