Method and device for preparing anti-corrosion protective layer on uranium surface by atmospheric laser passivation

An anti-corrosion and laser technology, which is applied in the field of material and metal surface passivation film preparation, can solve the problems of uranium nitride film corrosion, limited workpiece size, and difficulty in meeting industrial production applications, so as to reduce procedures, reduce production costs, The effect of simplifying equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The steps of preparing the passivation protection layer are as follows:

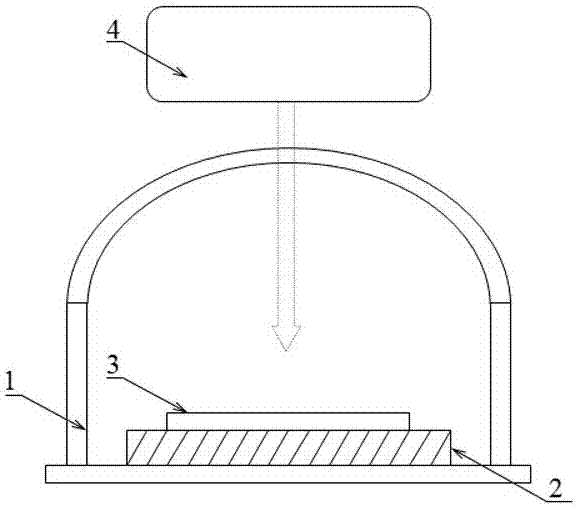

[0049] 1) Open the quartz glass cover 1, place the uranium workpiece 3 on the workbench 2, and close the quartz glass cover 1;

[0050] 2) Turn on the pulse laser scanning system 4 to scan the laser on the surface of the workpiece, and the laser energy density is 20J / cm 2 , the laser overlap rate is 95%;

[0051] 3) After the laser scans the entire surface of the workpiece, turn off the laser scanner, open the glass cover, and take out the workpiece to obtain a passivation protective layer on the surface of the workpiece.

[0052] As determined by XRD: the passivation protection layer prepared in this embodiment is mainly composed of uranium dioxide and UN, and the content of uranium dioxide is much higher than that of UN, that is, the passivation protection layer is a uranium nitrogen oxide passivation film.

Embodiment 2

[0054] 1) Open the quartz glass cover 1, place the uranium workpiece 3 on the workbench 2, and close the quartz glass cover 1;

[0055] 2) Turn on the pulse laser scanning system 4 to scan the laser on the surface of the workpiece, and the laser energy density is 50J / cm 2 , the laser overlap rate is 90%;

[0056] 3) After the laser scans the entire surface of the workpiece, turn off the laser scanner, open the glass cover, and take out the workpiece to obtain a passivation protective layer on the surface of the workpiece.

[0057] As determined by XRD: the passivation protection layer prepared in this embodiment is mainly composed of uranium dioxide and UN, and the content of uranium dioxide is much higher than that of UN, that is, the passivation protection layer is a uranium nitrogen oxide passivation film.

Embodiment 3

[0059] 1) Open the quartz glass cover 1, place the uranium workpiece 3 on the workbench 2, and close the quartz glass cover 1;

[0060] 2) Turn on the pulse laser scanning system 4 to scan the laser on the surface of the workpiece, and the laser energy density is 70J / cm 2 , the laser overlap rate is 80%;

[0061] 3) After the laser scans the entire surface of the workpiece, turn off the laser scanner, open the glass cover, and take out the workpiece to obtain a passivation protective layer on the surface of the workpiece.

[0062] As determined by XRD: the passivation protection layer prepared in this embodiment is mainly composed of uranium dioxide and UN, and the content of uranium dioxide is much higher than that of UN, that is, the passivation protection layer is a uranium nitrogen oxide passivation film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com