Ultrasonic nondestructive detection characteristic imaging system based on LabVIEW

A feature imaging, non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, special data processing applications, instruments, etc., to achieve the effects of easy function upgrade, good data format compatibility, and powerful imaging functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

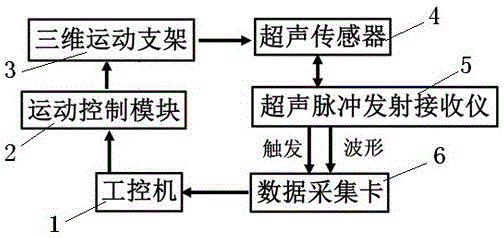

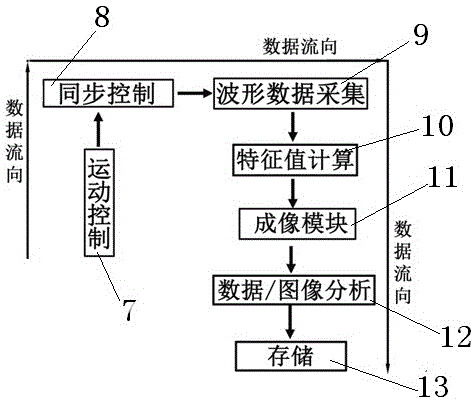

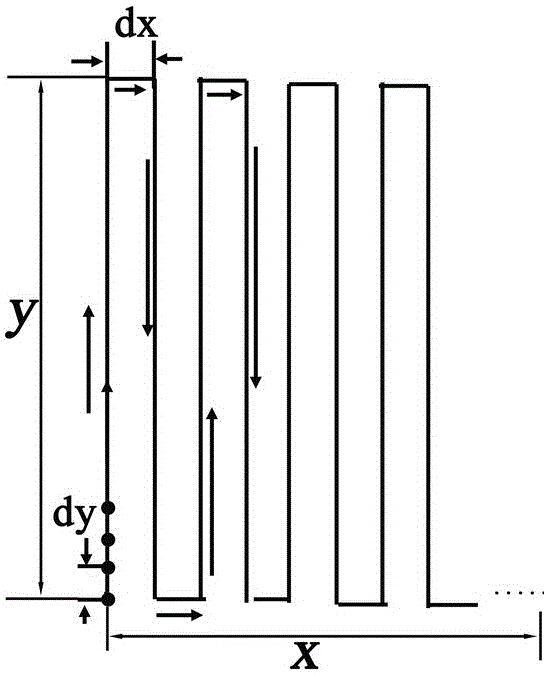

[0024] figure 1 Shows the schematic diagram of the hardware components of the LabVIEW-based ultrasonic nondestructive testing characteristic imaging system. The industrial computer sends motion control commands to the motion controller's single-chip computer through the serial port, so that the stepper motor driver sends driving pulses to drive the stepper motor on the three-dimensional motion bracket to rotate , The stepping motor cooperates with the screw to make the ultrasonic sensor mounted on the sliding table perform C-scan motion. The ultrasonic pulse transmitter receiver excites and receives the ultrasonic detection signal through the ultrasonic sensor, and also provides the trigger signal of digital-analog conversion for the data acquisition card; the data acquisition card receives the detection signal according to the trigger signal sent by the pulse transmitter receiver and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com