High voltage cable applied to power system

A technology for high-voltage cables and power systems, applied to power cables with shielding layers/conductive layers, insulated cables, cables, etc., to achieve the effects of easy mass production, low cable cost, and easy extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

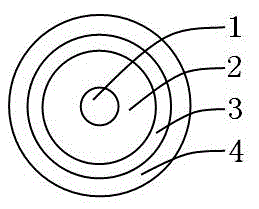

[0081] please see figure 1 , a high-voltage cable for power systems, with a conductor 1 located in the center, a shielding layer 3 located outside the conductor, and a sheath layer 4 located outside the shielding layer; it is characterized in that there is a high-voltage resistant layer 2 between the conductor and the shielding layer , the high pressure resistant layer is made of the following raw materials in parts by weight:

[0082] High-density polyethylene: 50-70 parts;

[0083] Linear low-density polyethylene: 15 to 30 parts;

[0084]Dysprosium oxide: 1 to 3 parts;

[0085] Polytetrafluoroethylene: 5 to 10 parts;

[0086] Tricobalt tetroxide: 1 to 3 parts;

[0087] Magnesium hydroxide: 10-15 parts;

[0088] Antioxidant 1010: 3 to 5 parts;

[0089] Silicon dioxide: 10-20 parts;

[0090] Calcium zirconate: 5-8 parts;

[0091] Zirconium dioxide: 5-10 parts;

[0092] Barium zirconate: 5-8 parts;

[0093] Polyethylene wax: 6-8 parts;

[0094] Manganese dioxide: 1 t...

Embodiment 2

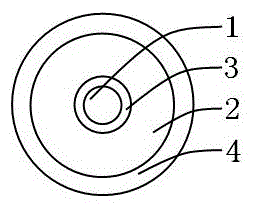

[0098] please see figure 2 , a high-voltage cable for power systems, has a conductor 1 located in the center, a shielding layer 3 located outside the conductor, and a sheath layer 4 located outside the shielding layer; it is characterized in that the shielding layer and the sheathing layer have a high-voltage resistant Layer 2, the high pressure resistant layer is made of the following raw materials in parts by weight:

[0099] High-density polyethylene: 50-70 parts;

[0100] Linear low-density polyethylene: 15 to 30 parts;

[0101] Dysprosium oxide: 1 to 3 parts;

[0102] Polytetrafluoroethylene: 5 to 10 parts;

[0103] Tricobalt tetroxide: 1 to 3 parts;

[0104] Magnesium hydroxide: 10-15 parts;

[0105] Antioxidant 1010: 3 to 5 parts;

[0106] Silicon dioxide: 10-20 parts;

[0107] Calcium zirconate: 5-8 parts;

[0108] Zirconium dioxide: 5-10 parts;

[0109] Barium zirconate: 5-8 parts;

[0110] Polyethylene wax: 6-8 parts;

[0111] Manganese dioxide: 1 to 3 pa...

Embodiment 3

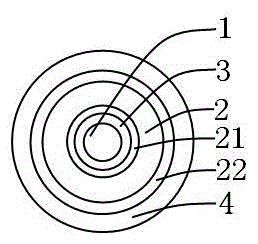

[0115] please see image 3 , a high-voltage cable for power systems, has a conductor 1 located in the center, a shielding layer 3 located outside the conductor, an inner sheath 21 located outside the shielding layer, a first armored layer 22 located outside the inner sheath, and a first The sheath layer 4 outside the armor layer; it is characterized in that there is a high-voltage resistant layer 2 between the inner sheath and the first armor layer, and the high-voltage resistant layer is made of the following raw materials in parts by weight:

[0116] High-density polyethylene: 50-70 parts;

[0117] Linear low-density polyethylene: 15 to 30 parts;

[0118] Dysprosium oxide: 1 to 3 parts;

[0119] Polytetrafluoroethylene: 5 to 10 parts;

[0120] Tricobalt tetroxide: 1 to 3 parts;

[0121] Magnesium hydroxide: 10-15 parts;

[0122] Antioxidant 1010: 3 to 5 parts;

[0123] Silicon dioxide: 10-20 parts;

[0124] Calcium zirconate: 5-8 parts;

[0125] Zirconium dioxide: 5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com