Manufacturing method of tft substrate and structure of tft substrate

A manufacturing method and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as difficulty in machine debugging, long time consumption, and strict requirements on mask accuracy, and achieve low production costs, Reduce production costs and make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0036] see figure 1 , the present invention at first provides a kind of manufacture method of TFT substrate, comprises the following steps:

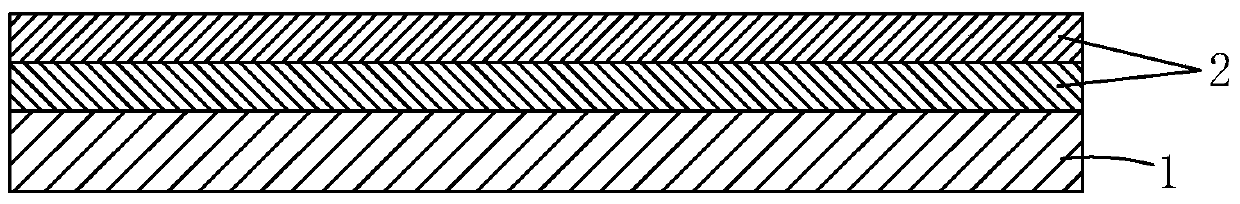

[0037] Step 1, such as figure 2 As shown, a substrate 1 is provided on which a buffer layer 2 is deposited.

[0038] Specifically, the substrate 1 may be a glass substrate or a plastic substrate.

[0039] Specifically, the buffer layer 2 may be a silicon oxide (SiOx) layer, a silicon nitride (SiNx) layer, or a composite layer of a silicon oxide layer and a silicon nitride layer. In this embodiment, the buffer layer 2 is a composite layer of a silicon oxide layer and a silicon nitride layer.

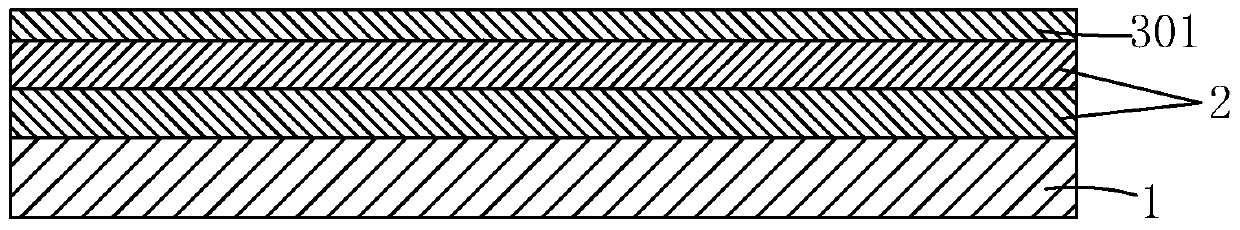

[0040] Step 2, such as image 3 As shown, an amorphous silicon (a-Si) thin film 301 is deposited on the buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com