Beta-cyfluthrin water-emulsion composition for preventing and controlling peach borer and preparation method thereof

A technology of high-efficiency cyfluthrin and peach borer, applied in botany equipment and methods, pesticides, applications, etc., can solve problems such as environmental pollution and economic waste, and achieve the effects of reducing costs, saving labor, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] S1. Dissolve 2.5 parts by mass of lambda-cyhalothrin in 10.0 parts by mass of ethanol to obtain solution A;

[0018] S2. The solution A obtained in step S1 is first added to a high-speed shearing machine, and at a speed of 500 rpm, 2.0 parts by mass of isotridecyl alcohol ethoxy compound and 6.0 parts by mass of phenethylphenol Vinyl ether, 0.2 parts by mass of xanthan gum, and 5.0 parts by mass of ethylene glycol were added to the high-speed shearing machine to obtain solution B (dispersed phase);

[0019] S3. Under the condition of rotating speed of 5000rpm, slowly add 74.3 parts by mass of deionized water (continuous phase) to the solution B obtained in step S2 (dispersed phase), after the addition, keep the rotating speed of 5000rpm for high-speed shearing, and the shearing time is not In less than 30 minutes, a Lambda-cyhalothrin aqueous emulsion is obtained.

Embodiment 2

[0021] S1. Dissolve 2.8 parts by mass of lambda-cyfluthrin in 11.0 parts by mass of ethanol to obtain solution A;

[0022] S2, S2, firstly add the solution A obtained in step S1 to the high-speed shearing machine, and slowly add 2.5 parts by mass of isotridecyl alcohol ethoxy compound and 6.5 parts by mass of phenethyl phenol under the condition of rotating speed of 800 rpm. Polyoxyethylene ether, 0.3 parts by mass of xanthan gum, and 6.0 parts by mass of ethylene glycol are added to the high-speed shearing machine to obtain solution B (dispersed phase);

[0023] S3. Under the condition of rotating speed of 8000rpm, slowly add 70.9 parts by mass of deionized water (continuous phase) to the solution B obtained in step S2 (dispersed phase). After the addition is completed, keep the rotating speed at 8000rpm for high-speed shearing. In less than 30 minutes, a Lambda-cyhalothrin aqueous emulsion is obtained.

Embodiment 3

[0025] S1. Dissolve 2.65 parts by mass of lambda-cyfluthrin in 10.5 parts by mass of ethanol to obtain solution A;

[0026] S2. The solution A obtained in step S1 is first added to a high-speed shearing machine, and 2.25 parts by mass of isotridecyl alcohol ethoxy compound and 6.25 parts by mass of phenethylphenol polyoxygen Vinyl ether, 0.25 parts by mass of xanthan gum, and 5.5 parts by mass of ethylene glycol were added to the high-speed shearing machine to obtain solution B (dispersed phase);

[0027] S3. Under the condition of rotating speed of 6500rpm, slowly add 72.6 parts by mass of deionized water (continuous phase) to the solution B obtained in step S2 (dispersed phase). After the addition is completed, keep the rotating speed at 6500rpm for high-speed shearing. In less than 30 minutes, a Lambda-cyhalothrin aqueous emulsion is obtained.

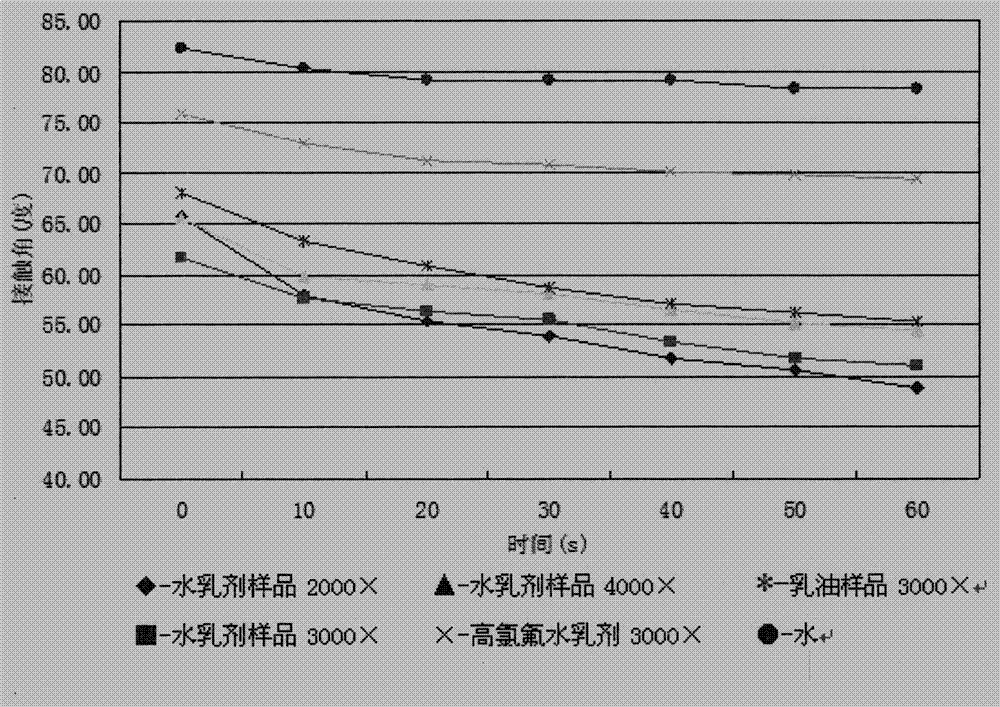

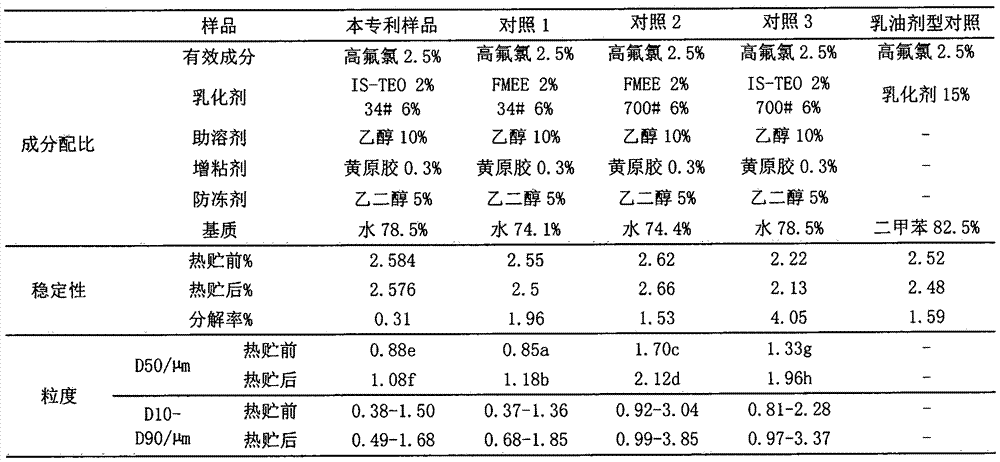

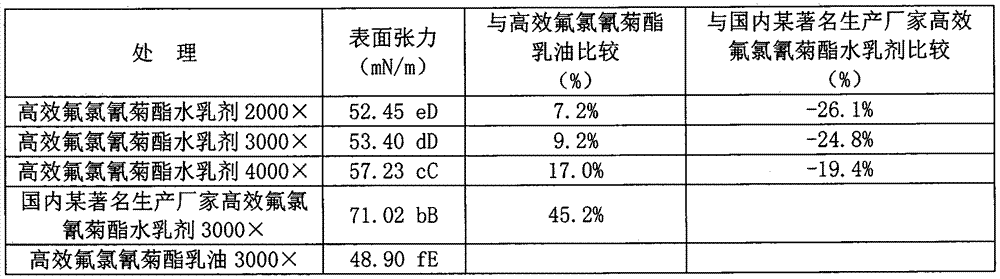

[0028] The composition, decomposition rate, liquid particle size, surface tension of the diluent, the static contact angle of the diluen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com