Method for extracting high-purity rice glutelin

An extraction method and glutenin technology, which is applied in the field of rice glutenin extraction, can solve the problems of dark brown substances and intensified Maillard reaction, and achieve the effect of avoiding Maillard reaction and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

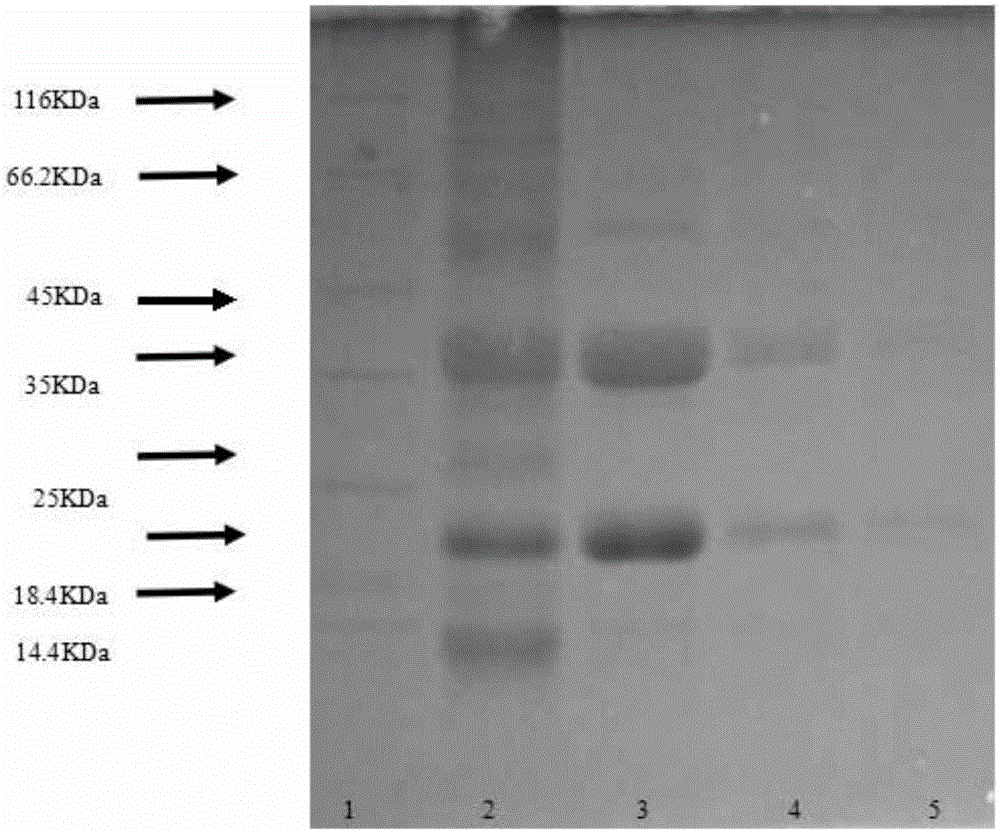

[0027] Specific embodiment one: the extraction method of the high-purity rice glutenin of the present embodiment is carried out according to the following steps:

[0028] 1. Grinding rice into rice flour;

[0029] 2. Degreasing the rice flour with n-hexane for 3 to 5 times to obtain defatted rice flour;

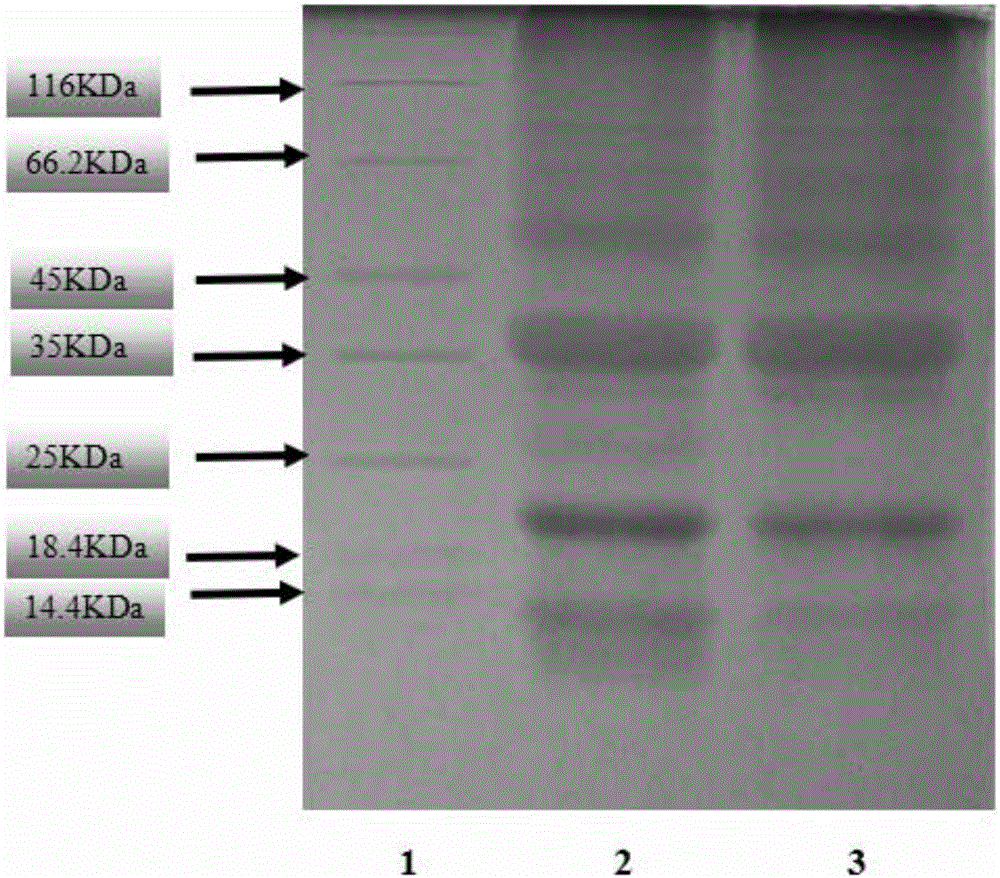

[0030] 3. Remove albumin, globulin and prolamin from defatted rice flour to obtain precipitation;

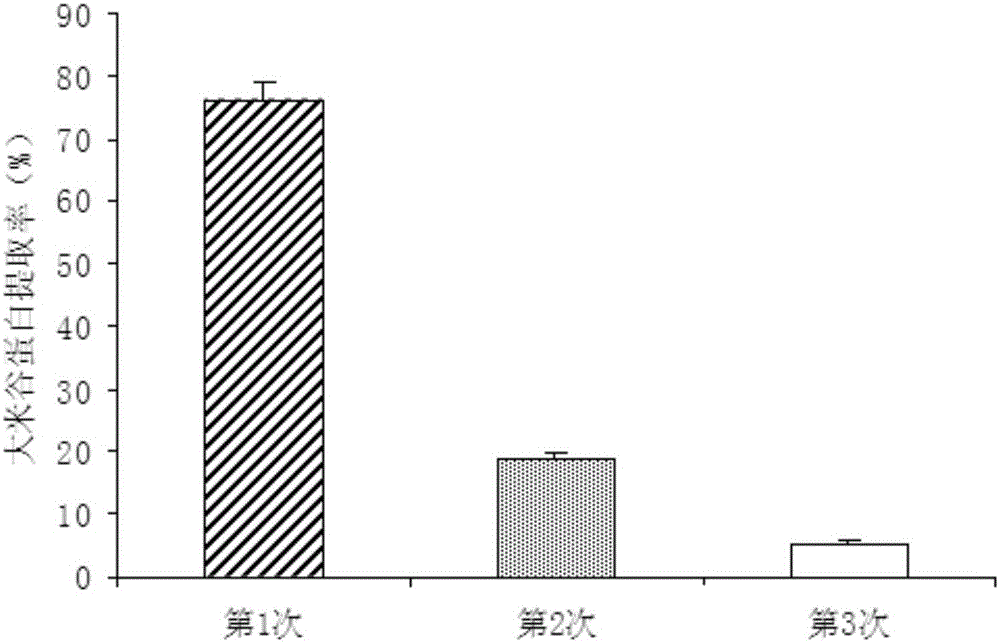

[0031] Four, the precipitation that step 3 obtains is that the concentration of 0.8%~1.2% (w / v) extracts gluten 3~5 times with lactic acid;

[0032] 5. Combine the supernatant collected by each extraction, and use the TCA solution with a concentration of 8% to 12% (w / v) to carry out protein precipitation on the supernatant;

[0033] 6. Washing the precipitate with PBS buffer solution for 3 to 5 times, vacuum freeze-drying the washed precipitate to obtain rice gluten.

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the specific method of grinding rice into rice flour in step 1 is: grind fresh rice with a pulverizer for 15-20 seconds each time, 30-40 times in total. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: what this embodiment is different from specific embodiment one is: in step 2, the concrete method that rice flour is degreased with n-hexane is:

[0036] A. Mix rice flour and n-hexane according to the ratio of 1g:4~6mL, stir at room temperature for 1h, let stand for 1h, and then centrifuge at 4000rpm for 20min to collect the precipitate;

[0037] B. Repeat step A for 2 to 4 times, and dry the collected precipitate in a water bath at 30° C. to obtain defatted rice flour. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com