A kind of highly emulsifying pure vegetable oat milk and its preparation method

An emulsifying, pure plant technology, applied in the field of high emulsifying pure plant oat milk and its preparation, can solve the problems of difficult to grasp the degree of proteolysis, easy thermal denaturation of proteins, poor substrate specificity, etc., and achieve functional properties. Improve, enhance nutritional value and taste, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A highly emulsifying pure vegetable oat milk, including the following raw materials in mass ratio: oat 20%, coconut oil 5%, inulin 1.5%, dipotassium hydrogen phosphate 0.4%, salt 0.1%, soybean lecithin 0.1%, natural Vitamin E 0.002% and the balance water.

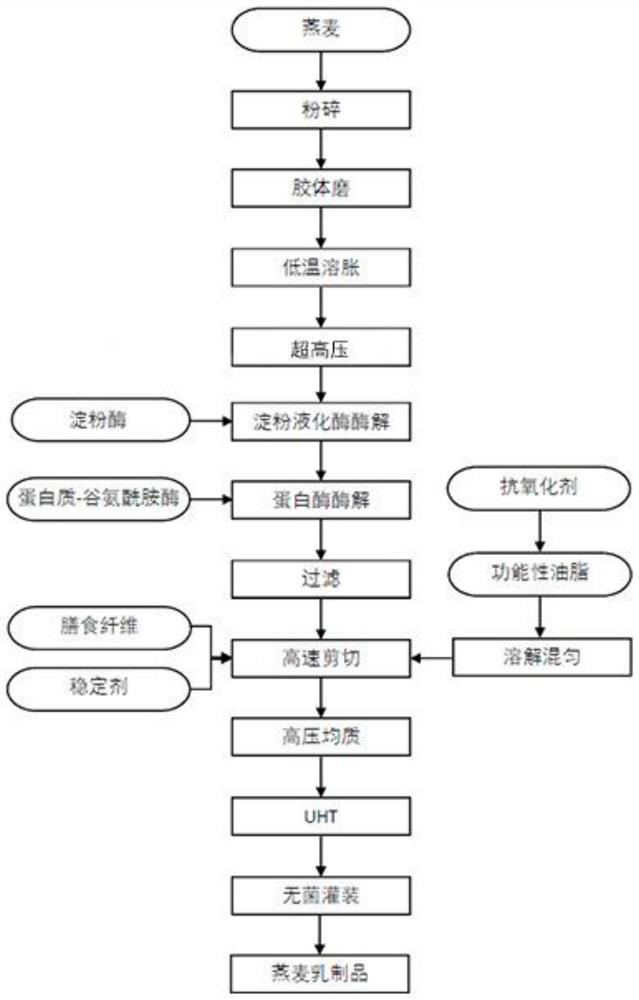

[0052] The preparation method of the present embodiment is as follows:

[0053] S1, material crushing: crush the oats to 80 mesh;

[0054] S2, colloid mill: Add room temperature demineralized water to the oat flour obtained in step S1, stir evenly, and control the mass concentration of oat to 20%, then use colloid mill to refine slurry until the slurry can pass through a 100-mesh screen;

[0055] S3. Low-temperature swelling and ultra-high pressure treatment: heat the oat pulp obtained in step S2 to 60° C. and swell at low temperature for 30 minutes; then put the warm-treated oat pulp into food-grade polyethylene plastic bags, vacuum seal them in Treat under 300Mpa high pressure for 20 minutes, keep the temperature...

Embodiment 2

[0065] A pure vegetable oat milk with high emulsification, including the following raw materials in mass ratio: oat 23%, linseed oil 1%, macadamia nut oil 1%, palm kernel oil 3%, resistant dextrin 1.5%, hexametaphosphoric acid Sodium 0.4%, table salt 0.2%, carrageenan 0.03%, rosemary extract 0.004% and the balance water.

[0066] The preparation method of the present embodiment is as follows:

[0067] S1, material crushing: crush the oats to 80 mesh;

[0068] S2, colloid mill: add demineralized water at normal temperature to the oat flour obtained in step S1, stir evenly, and control the mass concentration of oat to 23%, then use a colloid mill to refine the slurry until the slurry can pass through a 100-mesh screen;

[0069] S3. Low-temperature swelling and ultra-high pressure treatment: heat the oat pulp obtained in step S2 to 63° C. and swell at low temperature for 30 minutes; then put the warm-treated oat pulp into food-grade polyethylene plastic bags, vacuum-seal them in...

Embodiment 3

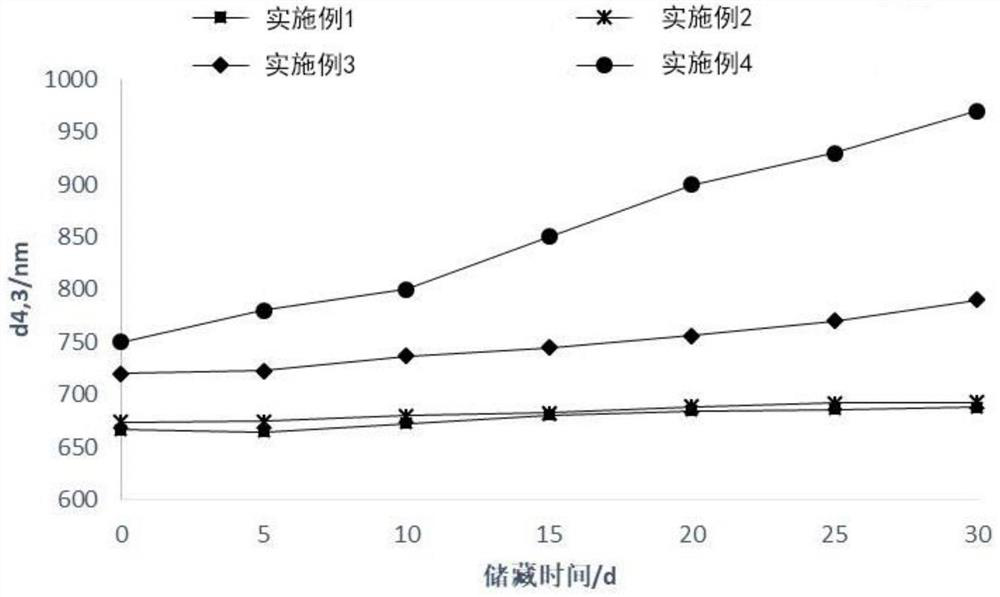

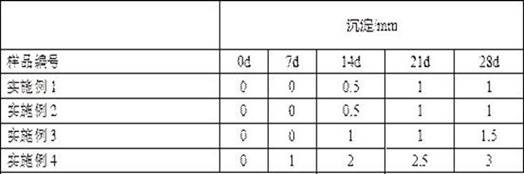

[0079] The raw materials of Example 3 are the same as those of Example 1, the only difference being that no ultra-high pressure is used in Step S3 of Example 3, and the oat pulp is directly subjected to the hydrolysis reaction of Step S4 after being swollen at low temperature, and the rest of the steps are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com