Processing method of roasted sweet potatoes

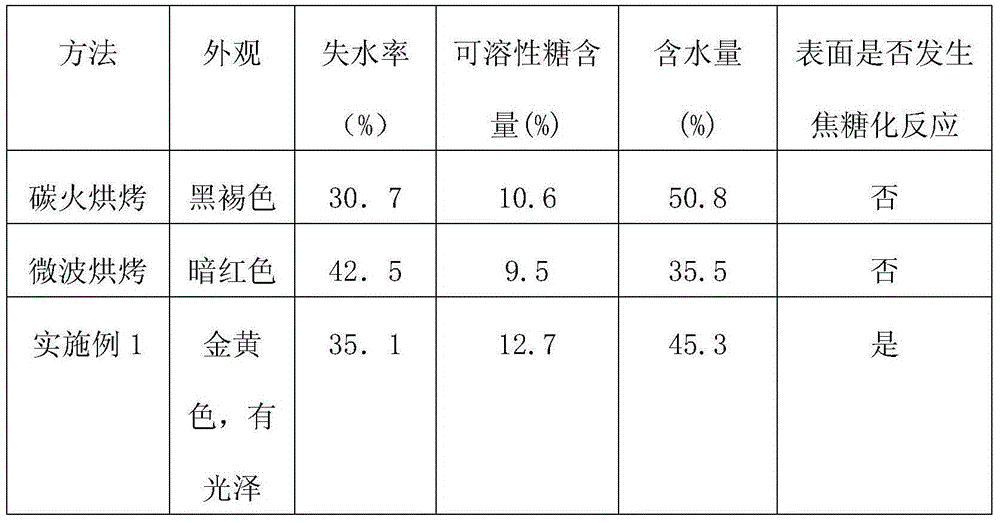

A processing method and technology of roasting sweet potatoes, which are applied in the field of food processing, can solve problems such as difficult quality management, and achieve the effects of unique flavor, convenient processing and eating, and good sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Choose three varieties of mature sweet potato roots, namely Guangshu 79, Xinnuo and Xinxiang. Each sweet potato root is more than 3cm in diameter. Wash and peel off the skin; cut the potato cubes into uniform small pieces, each small piece weighs about 50 grams after cutting.

[0065] Take 500 grams of barley malt and soak it in 5-8 times warm water for 1 hour, set aside.

[0066] Submerge the cut potato pieces in the barley malt extract and precook them, add maltose, fructose and glucose at the same time, precook them for 0.2h, and cook until they are half mature. The total weight of maltose, fructose and glucose is 10% of the weight of potato pieces, and the ratio of maltose, fructose and glucose is 1:1:1.

[0067] Take out the precooked sweet potato pieces, drain the surface moisture, and then bake them in a drying oven at a hot air drying temperature of 100°C.

[0068] Choose an oven with independent temperature adjustment up and down, the lower temperature is co...

Embodiment 3

[0079] Select mature sweet potato tubers of Xinnuo variety, and each sweet potato tuber has a diameter of more than 3cm. Wash and peel; cut the potato cubes into uniform small pieces, each small piece weighs about 80 grams after cutting.

[0080] Take 500 grams of barley malt and soak it in 6 times warm water for 2 hours, set aside.

[0081] Put the cut potato pieces into the barley malt extract and immerse them for precooking, add maltose and glucose at the same time, precook for 0.4h, and cook until they are half mature. Wherein the total weight of maltose and glucose is 15% of the weight of potato pieces, and the ratio of maltose and glucose is 2:1. Adding glucose and co-cooking can brighten the luster of potato cubes.

[0082] Take out the precooked sweet potato pieces, drain the surface moisture, and then bake them in a drying oven at a hot air drying temperature of 100°C.

[0083] Choose an oven with independent temperature adjustment up and down, the bottom temperatu...

Embodiment 4

[0086] Choose mature sweet potato tubers of the Xinxiang variety, and each sweet potato tuber has a diameter of more than 3 cm. Wash and peel; cut the potato cubes into uniform small pieces, each small piece weighs about 60 grams after cutting.

[0087] Submerge the cut potato pieces in water for precooking, add the roasted barley malt, maltose and fructose at the same time, precook for 0.25h, and cook until half mature. Wherein the total weight of maltose and fructose is 20% of the weight of potato pieces, and the ratio of maltose and fructose is 3:1. Adding fructose and cooking will increase the aroma of potato cubes.

[0088] Take out the precooked sweet potato pieces, drain the surface moisture, and then bake them in a drying oven at a hot air drying temperature of 100°C.

[0089] Choose an oven with independent temperature adjustment up and down, the lower temperature is controlled at 220°C, and the upper temperature is controlled at 240°C. Place the drained potato cub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com