Porous polymer with adjustable surface properties of interpenetrating network and preparation method thereof

An interpenetrating network type, porous polymer technology, applied in the field of two-phase separation of organic solvents and water, can solve the problems of limited volume, ignore the adverse impact of dispersed oil in water on the environment, hinder the application of oil spill repair materials, etc., and achieve simplification Recycling process, low preparation cost, green and pollution-free preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

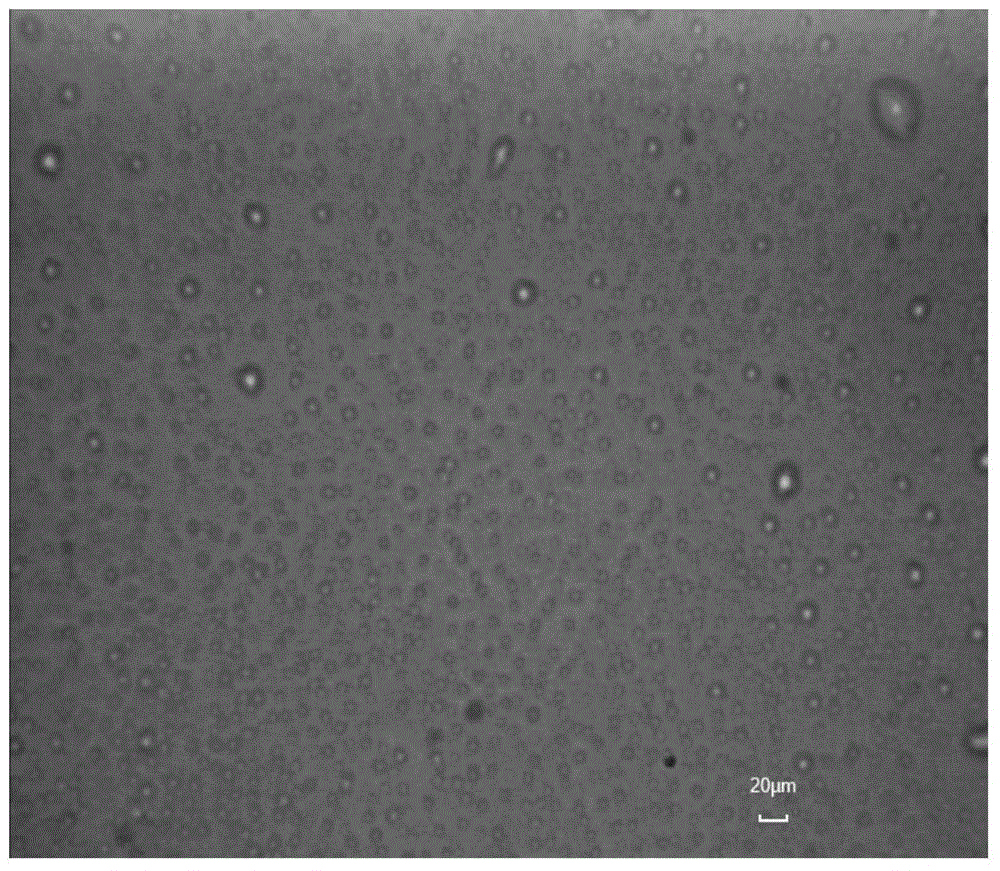

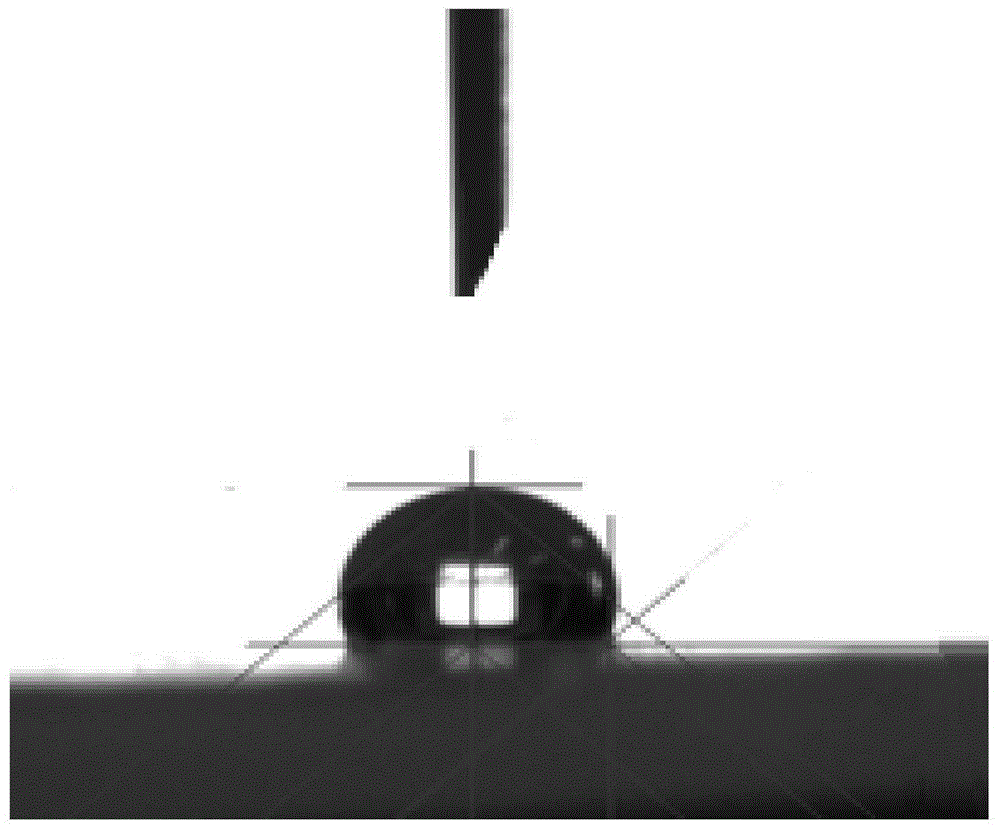

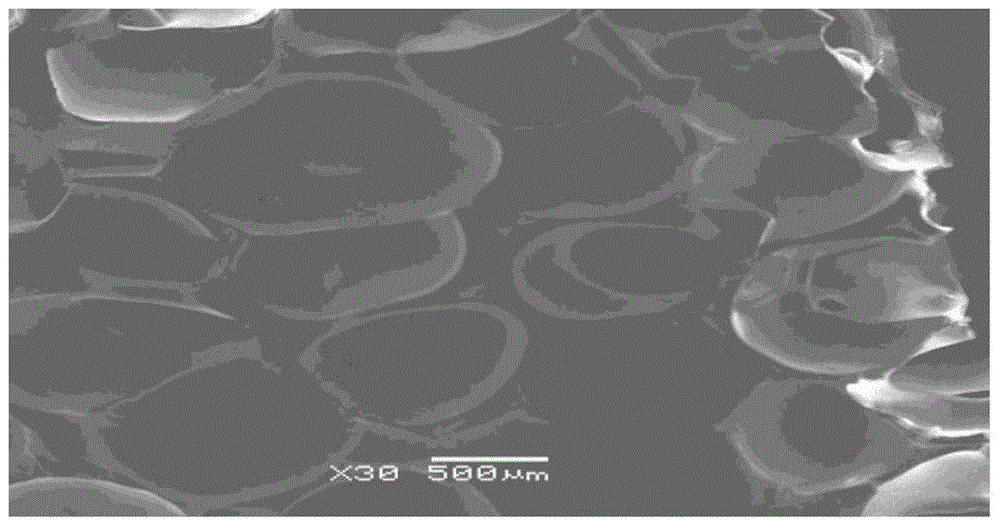

[0031] Such as Figure 1~5 As shown, the interpenetrating network-type porous polymer with adjustable surface properties is characterized in that it includes: a main body made of a porous material, and a layer of silicon rubber and paraffin microspheres are polymerized on the three-dimensional porous structure of the main body. Rubber / paraffin microsphere compound.

[0032] The porous material includes polyurethane sponge.

[0033] The material of the silicone rubber includes 107-2000 two-component room temperature vulcanized silicone rubber.

[0034] The manufacturer of 107-2000 two-component RTV silicone rubber is Jinan Guobang Chemical.

[0035] The paraffin microspheres are micron-scale paraffin microspheres.

[0036] A method for preparing a porous polymer with adjustable interpenetrating network surface properties, characterized in that it includes the following steps:

[0037] S01, cut the main body made of porous material into a suitable size according to actual ne...

Embodiment 2

[0046] Such as Figure 1~5 As shown, the interpenetrating network-type porous polymer with adjustable surface properties is characterized in that it includes: a main body made of a porous material, and a layer of silicon rubber and paraffin microspheres are polymerized on the three-dimensional porous structure of the main body. Rubber / paraffin microsphere compound.

[0047] The porous material includes polyurethane sponge.

[0048] The material of the silicone rubber includes 107-2000 two-component room temperature vulcanized silicone rubber.

[0049] The manufacturer of 107-2000 two-component RTV silicone rubber is Jinan Guobang Chemical.

[0050] The paraffin microspheres are micron-scale paraffin microspheres.

[0051] A method for preparing a porous polymer with adjustable interpenetrating network surface properties, characterized in that it includes the following steps:

[0052] S01, cut the main body made of porous material into a suitable size according to actual ne...

Embodiment 3

[0061] Such as Figure 1~5 As shown, the interpenetrating network-type porous polymer with adjustable surface properties is characterized in that it includes: a main body made of a porous material, and a layer of silicon rubber and paraffin microspheres are polymerized on the three-dimensional porous structure of the main body. Rubber / paraffin microsphere compound.

[0062] The porous material includes polyurethane sponge.

[0063] The material of the silicone rubber includes 107-2000 two-component room temperature vulcanized silicone rubber.

[0064] The manufacturer of 107-2000 two-component RTV silicone rubber is Jinan Guobang Chemical.

[0065] The paraffin microspheres are micron-scale paraffin microspheres.

[0066] A method for preparing a porous polymer with adjustable interpenetrating network surface properties, characterized in that it includes the following steps:

[0067] S01, cut the main body made of porous material into a suitable size according to actual ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com