Submerged tubular membrane element

A tubular membrane and submerged technology, applied in membrane technology, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve the problems of no application of tubular membrane, low production capacity, high energy consumption in operation, etc., to achieve Reduce production costs, save energy, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

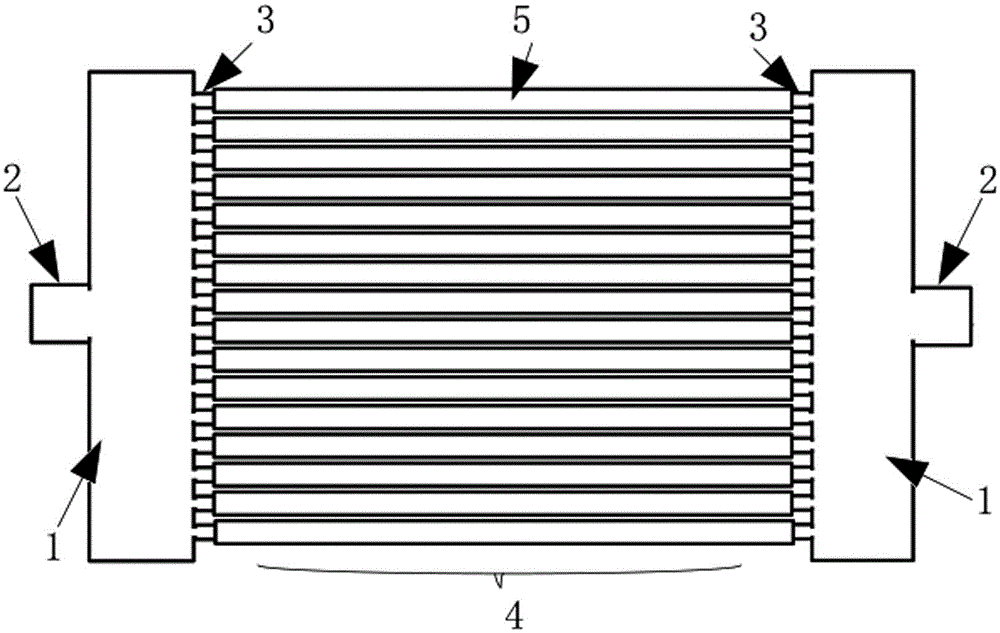

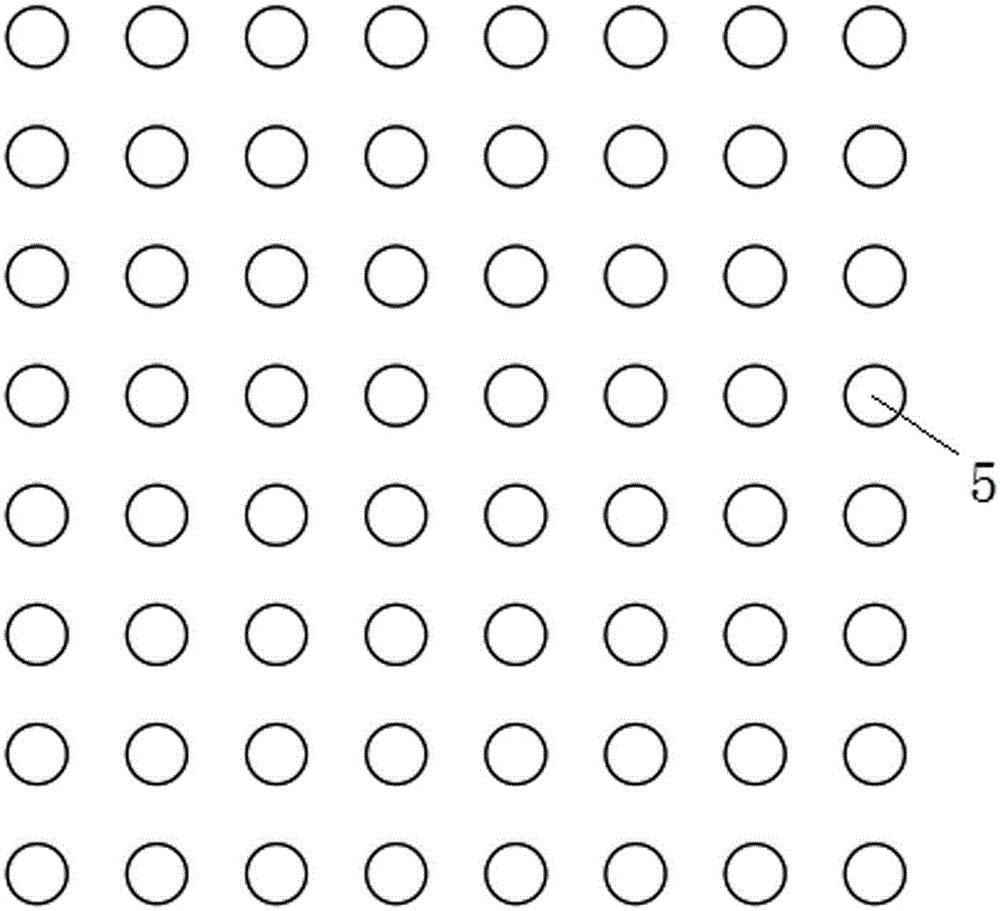

[0026] Example 1: Membrane water collection box 1 made of plastic mold, one side is DN40 water collection connection port 2, and the other side is 25×30 membrane tube connection port 3, which is connected by grouting and adhesive, tubular membrane tube 5 The outer diameter is 10mm, the inner diameter is greater than 8mm, the membrane material is PTFE, the membrane pore diameter is 0.3mm, the porosity is greater than 80%, and the support layer is 150g / m 2 Non-woven fabric, the membrane tube spacing is 15mm, the membrane tube length is 1000mm, and the double-sided water production collection box is used to ensure that the membrane water production flux is evenly distributed. The membrane element achieves an effective filtration area of 20m 2 , get 1000L / m in domestic sewage MBR 2 d(>40L / m 2 h) Stable operating flux, the transmembrane pressure difference is lower than 4Kpa, and the aeration intensity is lower than 6L / m 2 min, the backwash cycle is greater than 24 hours, and t...

Embodiment 2

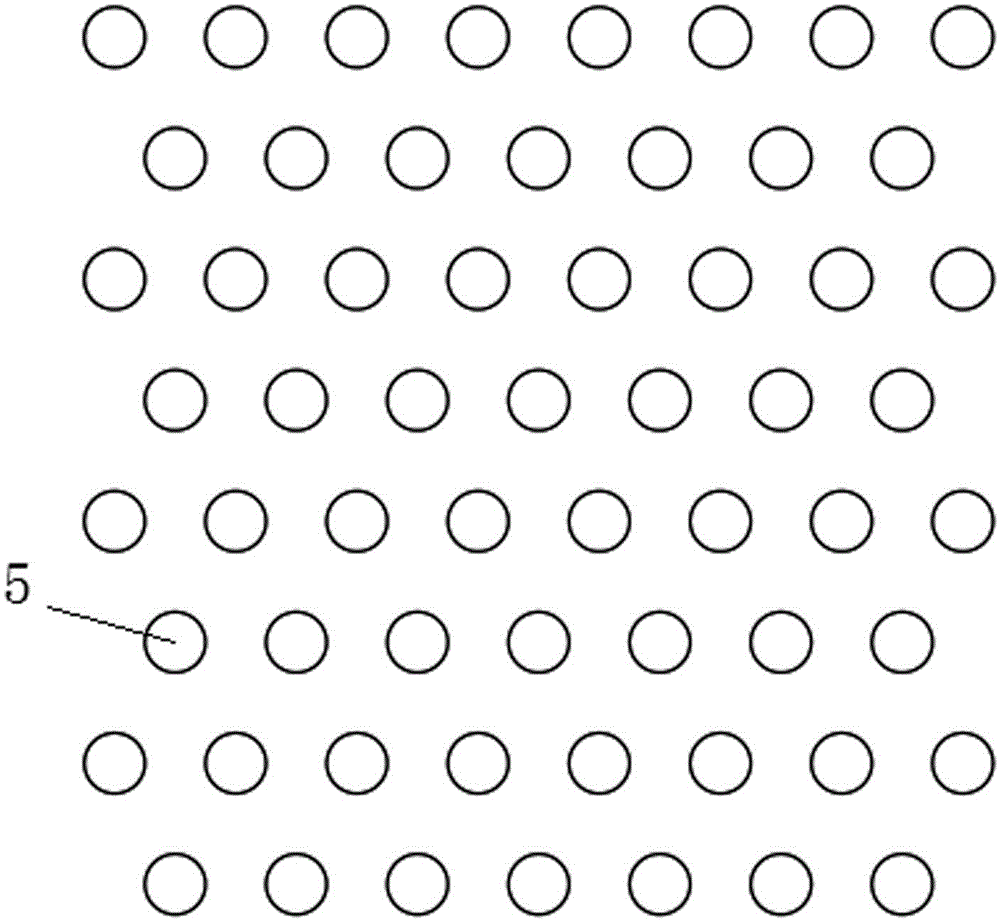

[0027] Example 2: Membrane water collection box 1 made of plastic mold, one side is DN40 water collection connection port 2, the other side is 7×11 membrane tube connection port 3, connected by ultrasonic or heat welding, tubular membrane tube 5 The outer diameter is 13mm, the inner diameter is greater than 9mm, the membrane material is PVDF, the membrane pore diameter is less than 0.1mm, and the support layer is 150g / m 2 Non-woven fabric, the membrane tube spacing is 20mm, the membrane tube length is 750mm, and the double-sided water production collection box is used to ensure that the water production flux of the membrane is evenly distributed. The membrane element achieves an effective filtration area of 2.3m 2 , get 140L / m in UF 2 h stable operating flux, the transmembrane pressure difference is lower than 18Kpa, and the aeration intensity is lower than 6L / m 2 min, the backwash cycle is greater than 24 hours, and the backwash intensity is 2L / m2 min(100Kpa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com