Method for preparing graphene static conductive tire

A technology of graphene and static electricity, which is applied in the field of preparation of graphene static electricity conductive tires, can solve the problems of public use and literature reports of static electricity conductive tires that have not yet been seen, and achieve the effects of no safety hazard, easy promotion and application, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

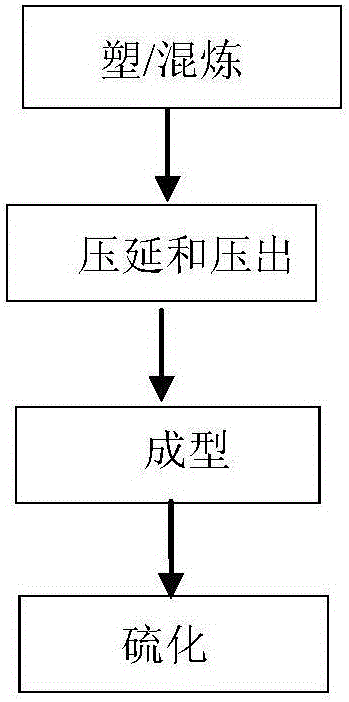

[0020] The present invention prepares graphene static conductive tires on the basis of medium-sized truck tire tread rubber and sidewall rubber, and its specific preparation process comprises the following steps:

[0021] (1), plastic / mixing: the tread rubber is composed of two parts: the crown rubber and the tread base rubber. One part of anti-aging agent was masticated at 45-50°C for 15-20 minutes to obtain the masticated rubber; and then the two-stage mixing process was used to knead the masticated rubber to obtain the crown rubber. First, mix the masticated rubber for 3-5min at 35-55°C, and then add 40-59.9 parts by weight of hard carbon black, 11 parts by weight of operating oil, 3 parts by weight of zinc oxide, and 2 parts by weight of hard carbon black. Fatty acid, 2 parts by weight of microcrystalline wax, and 0.7 parts by weight of anti-scorch agent are mixed evenly, and finally 0.1-20 parts by weight of graphene, 1.3 parts by weight of accelerator and 1.8 parts by we...

Embodiment 2

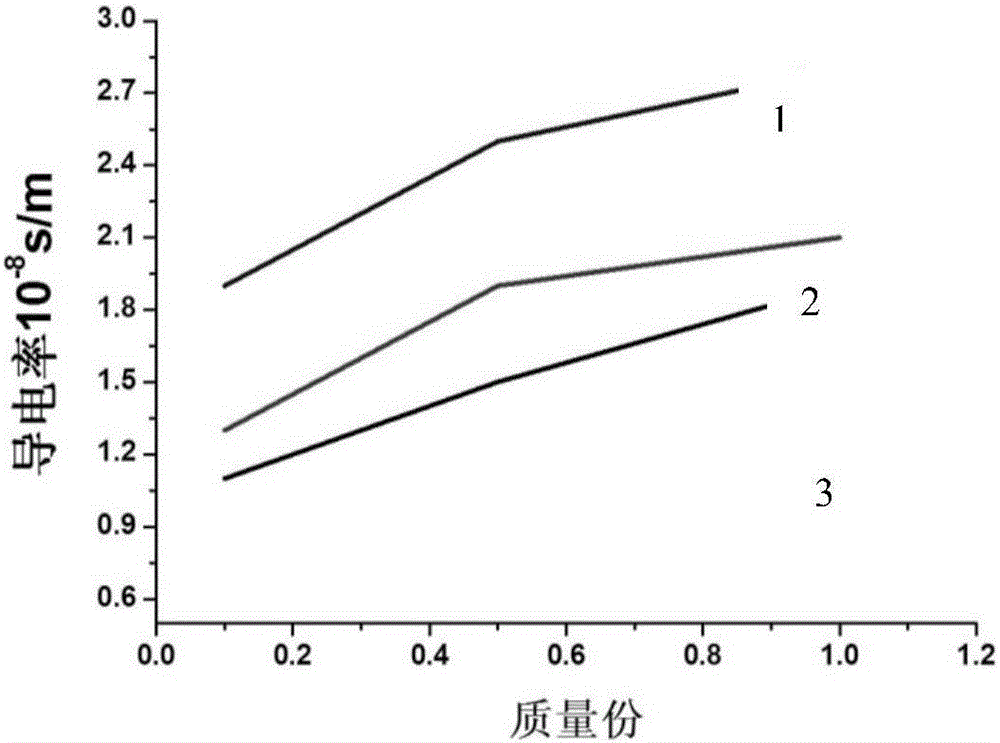

[0027] This embodiment tests the conductivity of the graphene static conductive tire prepared in Example 1 at 25°C, as figure 2 As shown, when the added amount of graphene is 0.1 weight part, 0.5 weight part and 1 weight part respectively, the specific surface area and conductivity of graphene powder are 1800m 2 / g, 9.7×10 5 s / m(1), 1600m 2 / g, 6×10 5 s / m(2),1200m 2 / g, 1×10 5 s / m(3), the test result curve shows that with the increase of graphene addition, the conductivity of the tire gradually increases; the higher the specific surface area and conductivity of the graphene powder, the higher the conductivity of the tire.

Embodiment 3

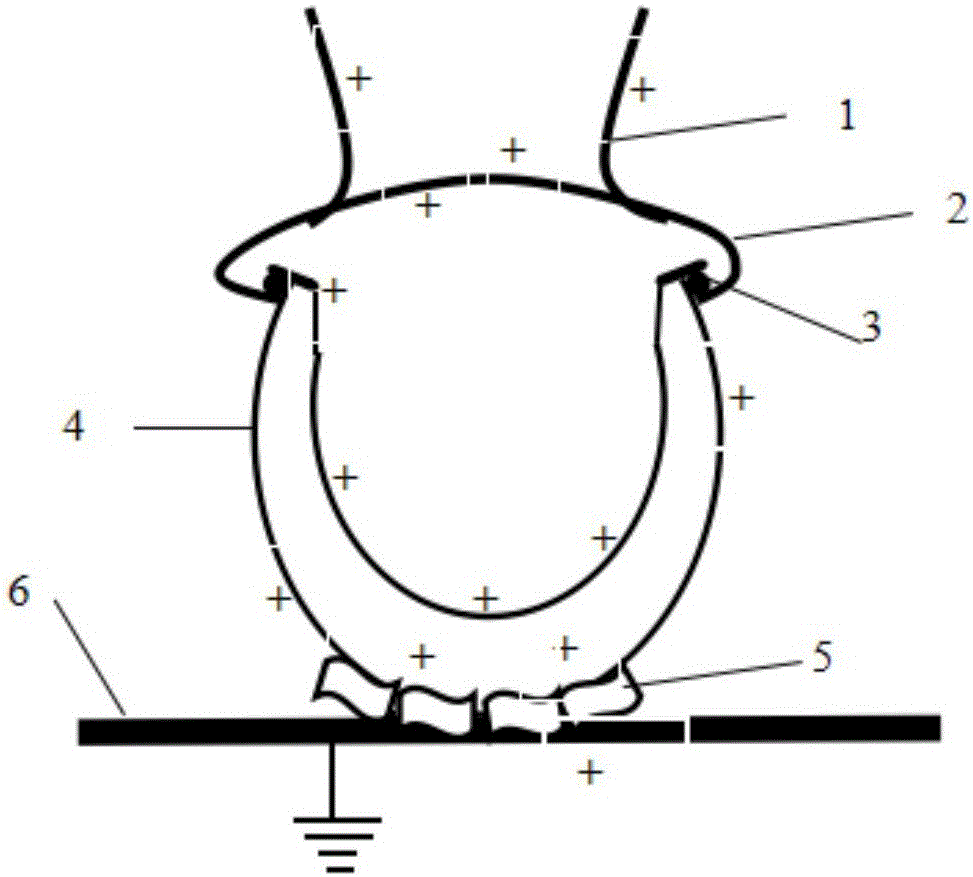

[0029] This embodiment illustrates the static conduction mechanism of the graphene static conduction tire prepared in Example 1, as image 3 As shown, the tire (sidewall 4 and tread 5) made by adding graphene powder is fitted and connected with the rim 2 on the metal wheel hub 1 of the automobile, and the static electricity (+) of the vehicle body is derived through the tire tread 5 contact surface 6, It can continuously and reliably export the static electricity of the car body at all times, and has an irreplaceable advantage in eliminating static electricity hazards for flammable and explosive goods transport vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com