Continuous preparation system and method for smokeless fireworks

A preparation system and technology for fireworks, applied in explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of poor uniformity of particle internal pore size distribution, thick smoke, and low production efficiency, so as to avoid particle agglomeration and process The effect of improving safety and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

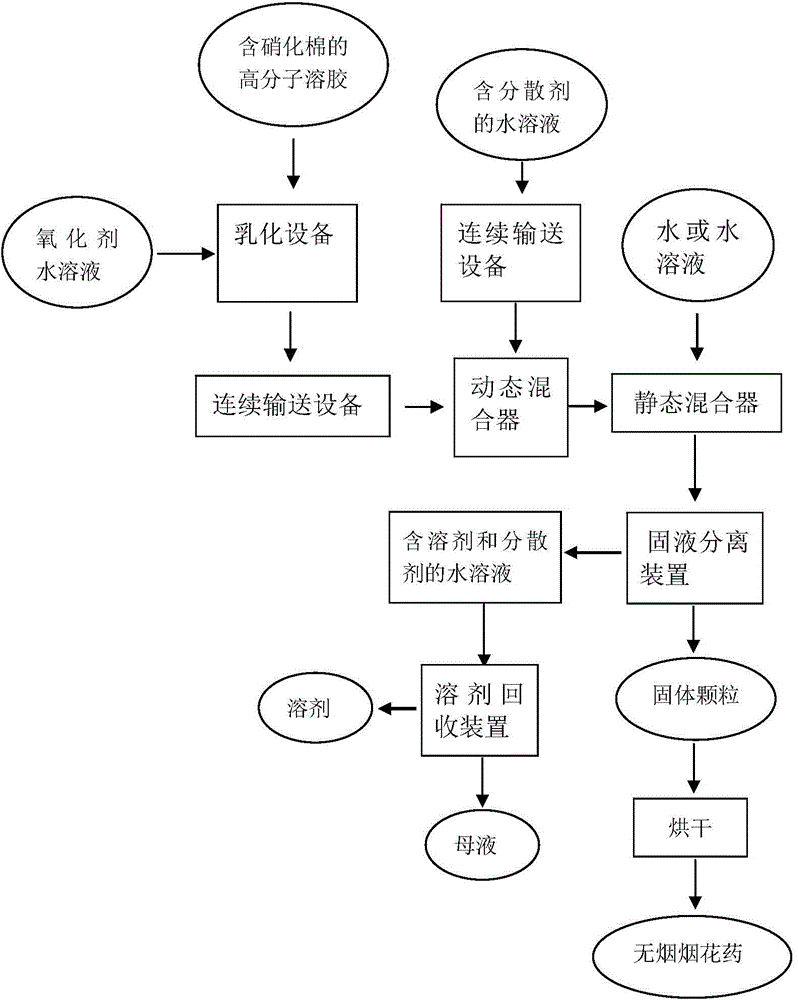

[0027] A method for continuously preparing smokeless fireworks anthers utilizing the above system, comprising the following steps:

[0028] (1) Step 1 is a material dissolving process. Under stirring, the energetic polymer material containing nitrocellulose is dissolved into a solvent to form a polymer sol. The energetic polymer material is one of nitrocellulose, single-base drug, and double-base drug with a nitrogen content greater than or equal to 11.5%, which can be called a raw material drug. Firstly, the energetic polymer material containing nitrocellulose is added to a material dissolving tank or a pelletizing reactor, and an ethyl acetate solvent 3.0 to 20 times the mass of the raw material drug is added to dissolve the material. Under the stirring state, the raw material drug is dispersed and dissolved to form a polymer sol. The dissolution time of the material is determined according to the type of raw material and the particle size, and the dissolution time is 10-90...

Embodiment 1

[0036] Four peristaltic pumps are used as the continuous conveying equipment for liquid materials, two of which respectively convey polymer emulsion and oxidant aqueous solution to the emulsifier, and the materials treated by the emulsifier are connected to the dynamic mixer through pipelines, and the aqueous solution containing dispersant is used for the first Three peristaltic pumps are sent to the other inlet of the dynamic mixer. The outlet of the dynamic mixer is connected to an inlet of the static mixer through a delivery pipeline. The aqueous solution containing oxidant is sent to the other inlet of the static mixer by a peristaltic pump. The pipeline is made of silicone tube, and the dynamic mixer is made of glass flat-bottomed airtight container, with a magnetic stirrer installed inside, driven by a magnetic stirring system outside, with adjustable speed, and a centrifugal device for solid-liquid separation of materials.

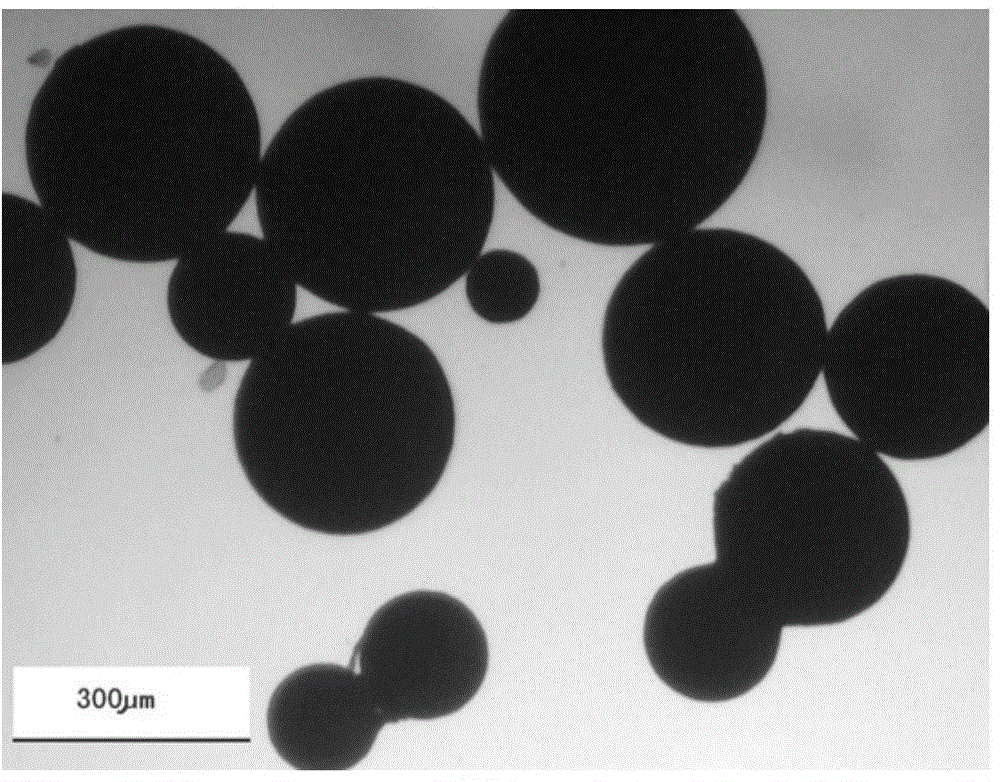

[0037] Select nitrogen content as the nitrocel...

Embodiment 2

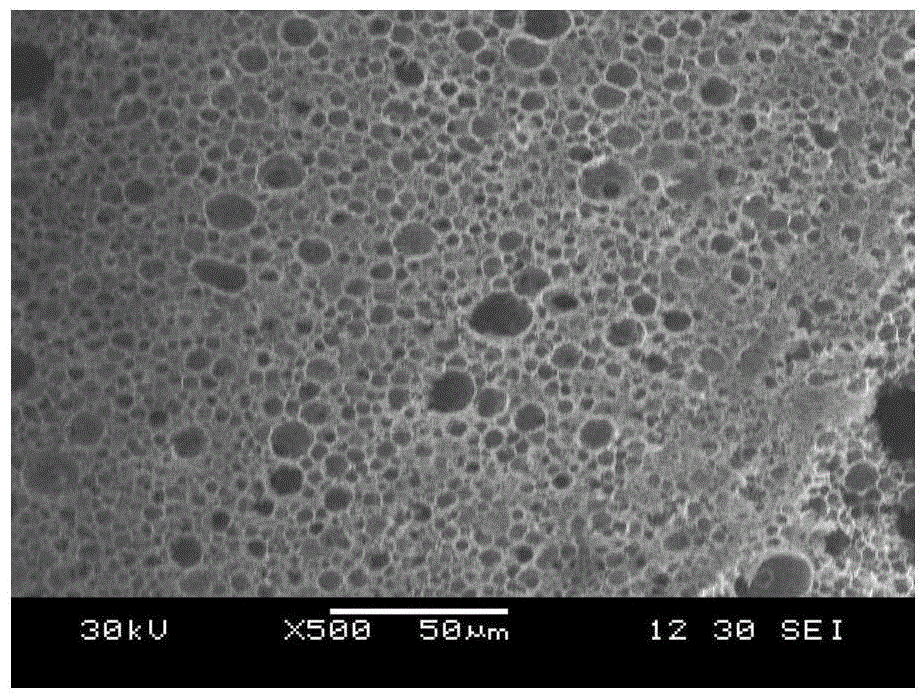

[0043] Using the basic process conditions similar to Example 1, only the concentration and feed flow ratio of some materials were changed. The nitrocellulose with a nitrogen content of 11.5% N is used as a raw material to form balls, the solvent ratio is 10 times, gum arabic is used as a dispersant, the concentration of the dispersant is 0.5%, and the aqueous solution contains OP-10 non-ionic surfactant. The surfactant concentration is 0.02%, the temperature of the material is maintained at 20-30° C., and other preparation conditions are the same as in Example 1. The particle size of the obtained smokeless fireworks anther particles is concentrated in the range of 0.2-1.0mm, and the SEM observation picture of a typical particle slice is shown in Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com