Continuous preparation system and method of energetic polymer microspheres

A polymer microsphere and polymer technology, which is used in offensive equipment, nitrification explosive components, and explosive processing equipment, etc., can solve the problem that spherical droplets are prone to deformation or agglomeration, affecting the compactness of propellant grains, and adverse product stability. and quality problems, to achieve the effect of increased spherical rate, low equipment cost and stable quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

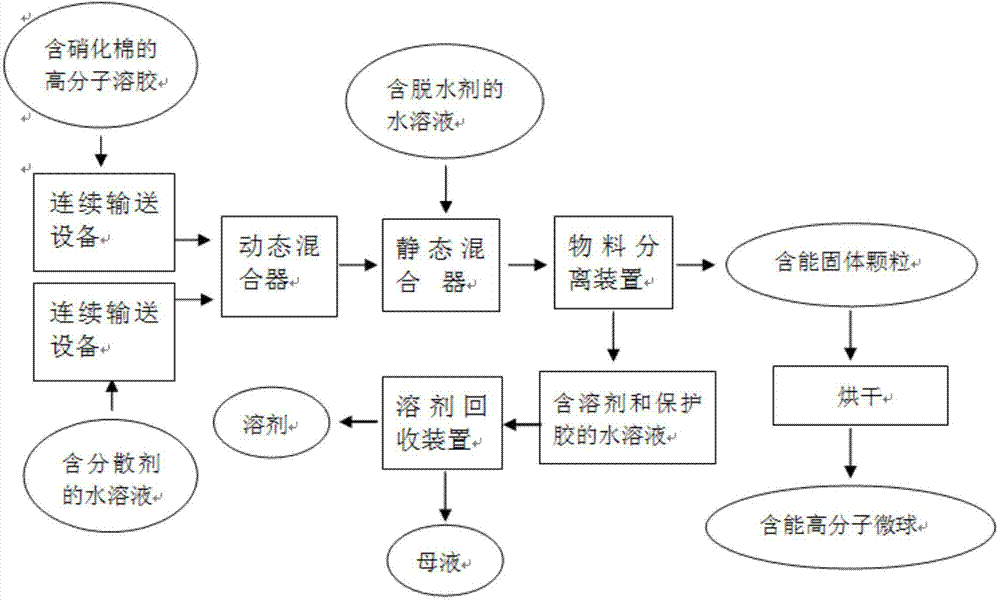

[0020] A method for continuously preparing energetic polymer microspheres utilizing the above system, comprising the following steps:

[0021] Step 1, dissolving the energetic polymer material containing nitrocellulose into ethyl acetate to form a polymer sol containing nitrocellulose; the energetic polymer material containing nitrocellulose is a nitrated nitrate with a nitrogen content greater than or equal to 11.5%. Cotton, single-base drug, double-base drug or modified double-base drug containing high-energy explosive; the amount of ethyl acetate is 2.0-50 times the mass of the energetic polymer material.

[0022] Step 2, transport the polymer sol containing nitrocellulose and the aqueous solution containing surfactant and dispersant in parallel, and carry out continuous mixing and dispersion in the dynamic mixer, and the polymer sol is dispersed into spherical droplets; the surface in the aqueous solution The mass concentration of active agent is 0.002-0.5%, and described ...

Embodiment 1

[0034] Three peristaltic pumps are used as continuous conveying equipment for liquid materials, two of which respectively convey the polymer sol and the aqueous solution containing dispersant to the two inlets of the dynamic mixer, and the outlet of the dynamic mixer passes through the conveying pipeline and the static mixer. One inlet is connected, and the aqueous solution containing dehydrating agent is transported to the other inlet of the static mixer by a third peristaltic pump. The delivery pipeline is made of silicone tube, and the dynamic mixer is made of a glass flat-bottomed airtight container with a magnetic stirrer inside. The external drive is driven by a magnetic stirring system, the speed is adjustable, and the solid-liquid separation of the material adopts a centrifugal device.

[0035] The nitrogen content that contains 35% moisture is selected to be the nitrocellulose of 11.5% as raw material drug, the wet nitrocellulose is added in the dissolving tank, the et...

Embodiment 2

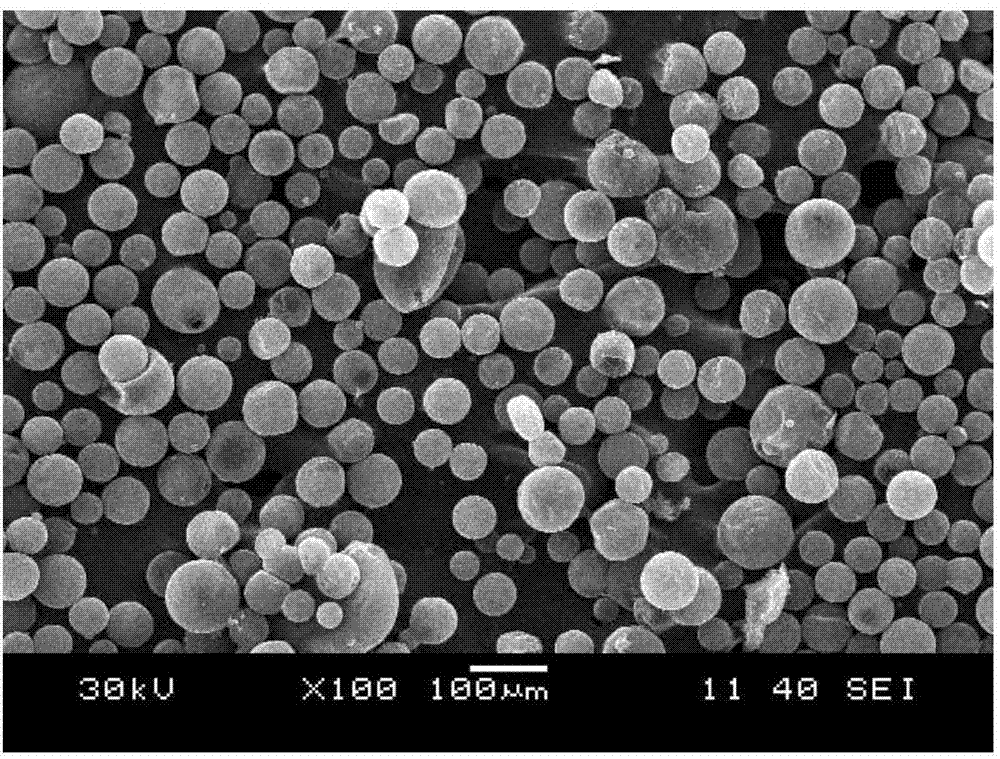

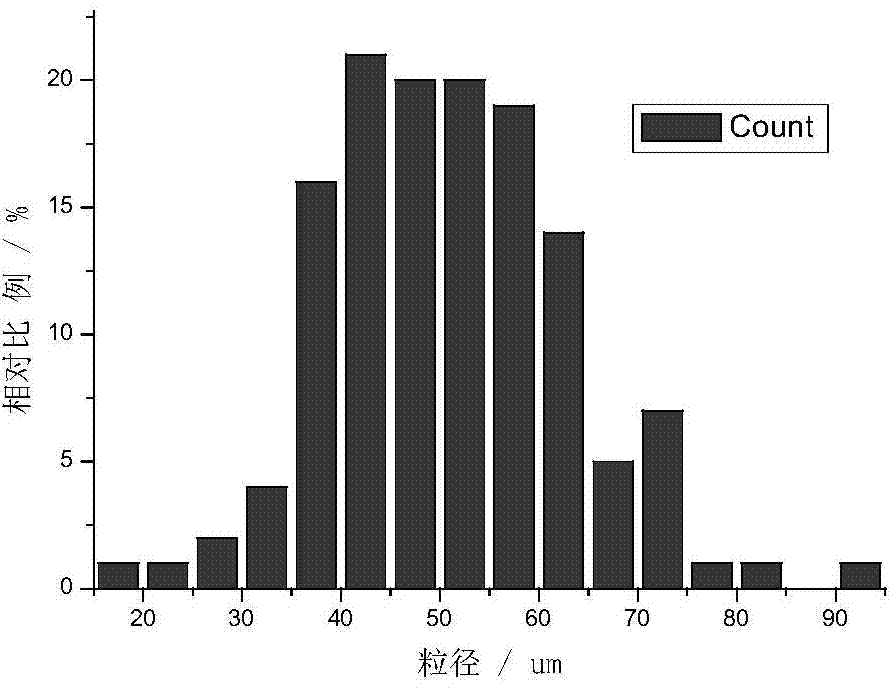

[0040] The continuous preparation of energetic polymer microspheres was carried out using the basic process conditions similar to those in Example 1, only the concentration of some materials and the ratio of feed flow rate were changed. Similarly, the nitrocellulose with a nitrogen content of 11.5%N is used as a raw material, the solvent ratio is 20 times, gum arabic is used as a dispersant, the concentration of the dispersant is 0.5%, and the aqueous solution contains OP-10 type nonionic surfactant. Surfactant concentration is 0.2%, and other preparation conditions are with embodiment 1. The obtained energetic polymer microspheres have an average particle diameter of 15.8 microns, and the appearance of the particles is as follows: Figure 4 As shown, the particle size distribution is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com