Synthetic method of 2-bromo-9,9-diphenylfluorene

A technology for diphenylfluorene and a synthesis method, which is applied in chemical instruments and methods, halogenated hydrocarbon preparation, organic chemistry, etc., can solve the problems of expensive trifluoromethanesulfonic acid, difficult post-processing, and high cost, and achieve good catalytic effect. , the effect of improving product yield and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

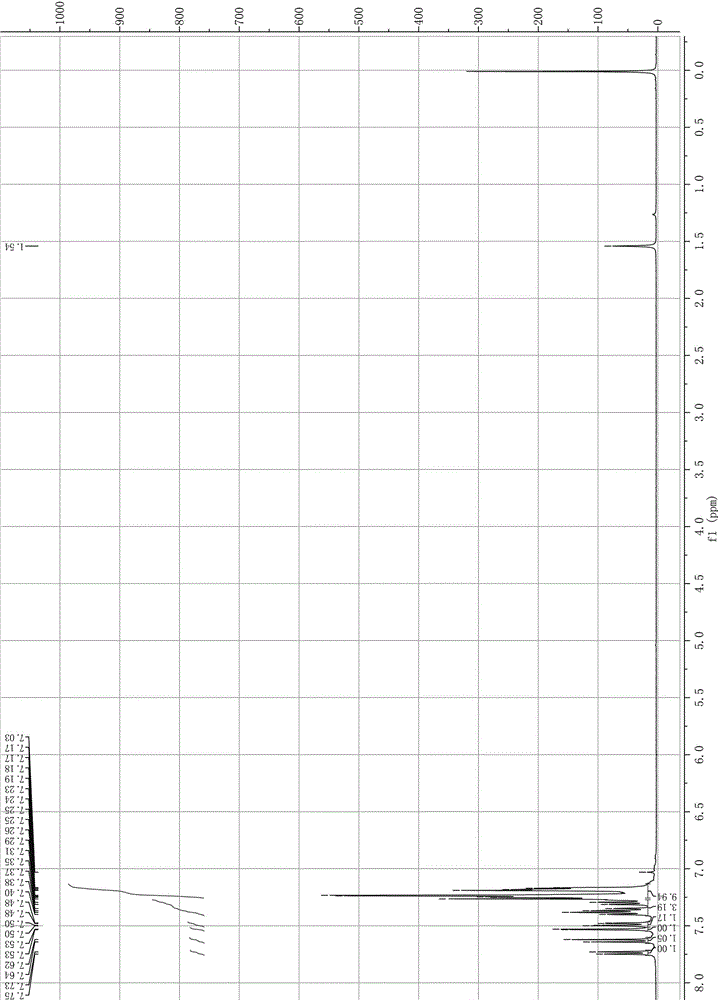

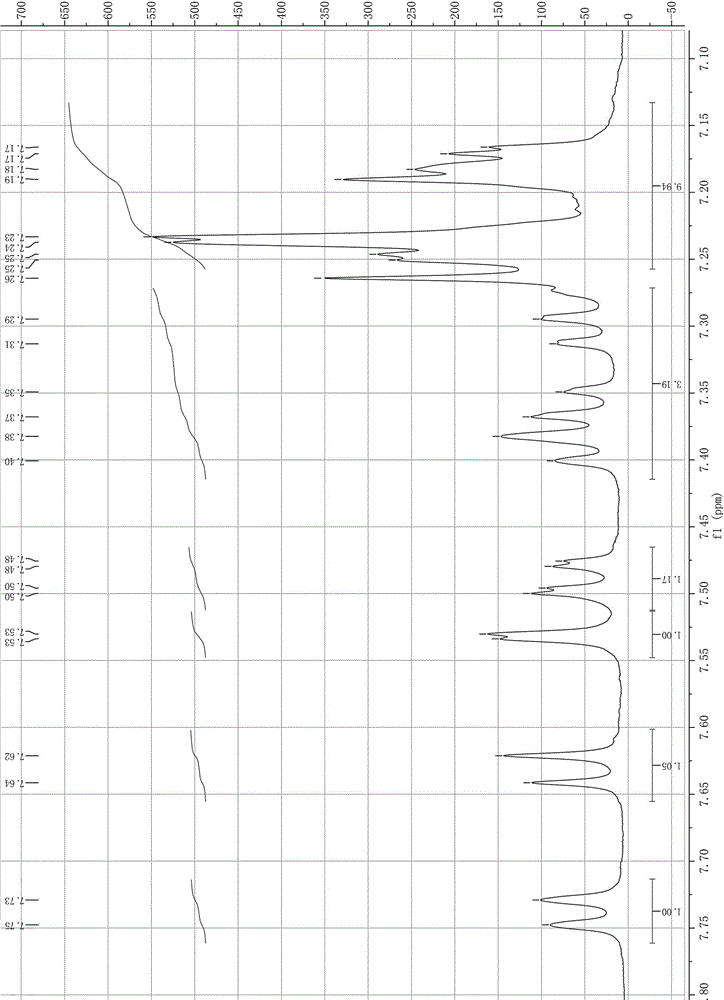

Image

Examples

Embodiment 1

[0025] The synthetic method of 2-bromo-9,9-diphenylfluorene comprises the following steps:

[0026] (1) Mix 10 mmol 2-bromo-9-phenyl-fluoren-9-ol and 100 mmol benzene, heat up to 61°C under stirring, and feed hydrogen chloride gas until the raw material point (2-bromo-9- Phenyl-fluorene-9-ol) basically disappeared. After ventilation, the reaction system was heated up to the reflux temperature, and refluxed for 1 hour. While refluxing, use a water separator to separate the water in the system;

[0027] (2) Cool the system to 17±2°C, add the catalyst in batches within 0.5h, after the addition is completed, raise the temperature to 35°C and react for 3.5h; the catalyst consists of 10mmol anhydrous aluminum trichloride and 1mmol anhydrous trichloride Composed of iron oxide, the catalyst was added in three batches, and the weight ratio of the three additions was 3:2:1;

[0028] (3) Separation and purification to obtain 2-bromo-9,9-diphenylfluorene. The separation and purification ...

Embodiment 2

[0030] The synthetic method of 2-bromo-9,9-diphenylfluorene comprises the following steps:

[0031] (1) Mix 10 mmol 2-bromo-9-phenyl-fluoren-9-ol and 180 mmol benzene, heat up to 66°C under stirring, and pass in hydrogen iodide gas until the raw material point basically disappears as monitored by TLC, and the ventilation is completed Finally, the reaction system was warmed up to the reflux temperature, and the reflux was completed for 1.5 h, and the moisture in the system was separated by a water separator while refluxing;

[0032] (2) Cool the system to 18±2°C, add the catalyst in batches within 0.5h, complete the addition, raise the temperature to 50°C for 4.5h and end; the catalyst consists of 12mmol anhydrous aluminum trichloride and 3mmol anhydrous trichloride Composed of iron oxide, the catalyst was added in three batches, and the weight ratio of the three additions was 3:2:1;

[0033] (3) Separation and purification to obtain 2-bromo-9,9-diphenylfluorene. The separatio...

Embodiment 3

[0035] The synthetic method of 2-bromo-9,9-diphenylfluorene comprises the following steps:

[0036] (1) Mix 10 mmol of 2-bromo-9-phenyl-fluoren-9-ol and 170 mmol of benzene, heat up to 64°C under stirring, and inject sufficient amount of hydrogen bromide gas until the raw material point basically disappears as monitored by TLC. After the ventilation is completed, the reaction system is heated to the reflux temperature, and the reflux is completed for 2 h, and the water in the system is separated by a water separator while reflux;

[0037] (2) Cool the system to 20±2°C, add the catalyst in batches within 1h, after the addition is completed, heat up to 45°C and react for 5h; the catalyst consists of 12mmol anhydrous aluminum trichloride and 3mmol anhydrous ferric chloride Composition, the catalyst is added in three batches, and the weight ratio of the three additions is 3:2:1;

[0038] (3) Separation and purification to obtain 2-bromo-9,9-diphenylfluorene. The separation and pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com