Caprolactam preparation method

The technology of caprolactam and inner sleeve is applied in the field of preparation of caprolactam, which can solve the problems of long process, limit the expansion of the production capacity of the device or the construction of a new device, etc., and achieve the effect of uniform material concentration and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example illustrates the method of the invention.

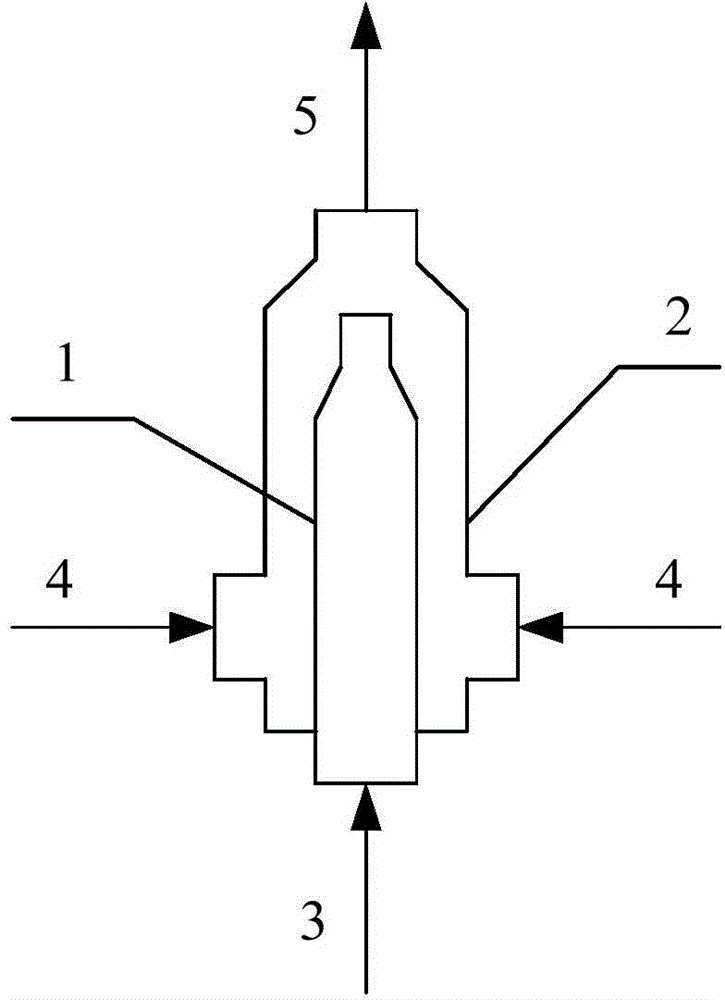

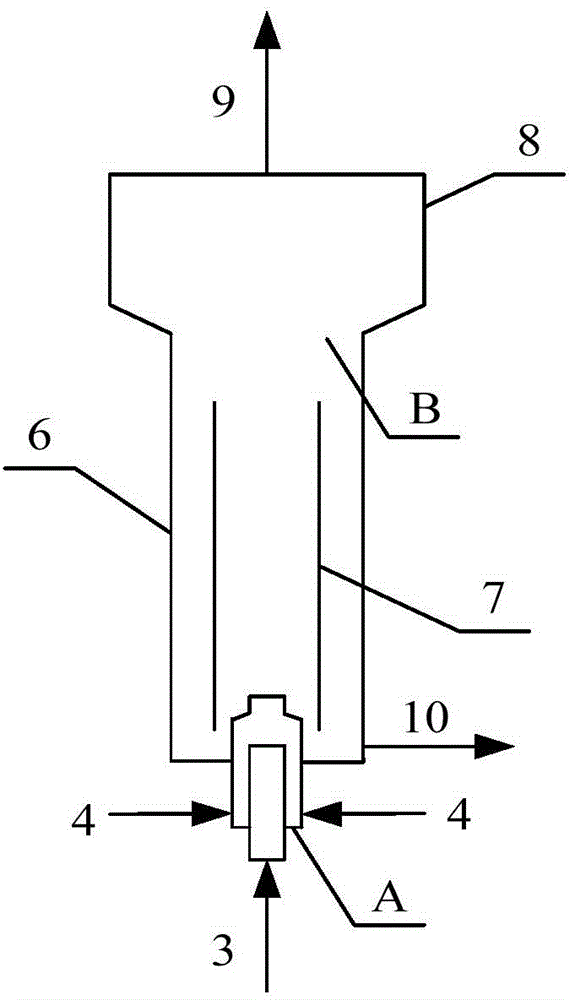

[0040] The diameter ratio of the inner sleeve to the outer sleeve of the reactor is 0.67, and the height of the inner sleeve is 3 times the diameter of the outer sleeve. The inner tube diameter of the mixing nozzle is 10mm, and the ratio of the inner tube diameter to the outer tube diameter is 0.75, and the linear velocity of the cyclohexanone oxime organic solution from the inner tube of the mixing nozzle is 40.5m / s, and the amidation liquid is in the inner tube of the mixing nozzle and The linear velocity of the annulus between the outer tubes is 24.9m / s. The upper part of the reactor is provided with an enlarged head section for the separation of gas-liquid two phases, and the ratio of the diameter of the enlarged head section to the diameter of the outer sleeve is 2:1.

[0041] Cyclohexanone oxime was fed as a hexane solution of cyclohexanone oxime at a concentration of 15 wt%. The feed rate of cyclohexanone ...

Embodiment 2

[0051] This example illustrates the method provided by the invention.

[0052] The reaction conditions are the same as in Example 1, except that the ratio of the diameter of the reactor inner sleeve to the outer sleeve is 0.67, and the height of the inner sleeve is 3 times the diameter of the outer sleeve. The inner tube diameter of the mixing nozzle is 15mm, and the ratio of the inner tube diameter to the outer tube diameter is 0.65, and the linear velocity of the cyclohexanone oxime organic solution from the inner tube of the mixing nozzle is 18.0m / s, and the amidation solution passes through the inner tube of the mixing nozzle and The linear velocity of the annulus between the outer tubes is 6.3m / s. The upper part of the reactor is equipped with an enlarged head section for the separation of gas-liquid two-phase, the ratio of the diameter of the enlarged head section to the diameter of the outer sleeve is 4:1

[0053] The reaction results are as follows: the conversion rat...

Embodiment 3

[0055] This example illustrates the method provided by the invention.

[0056] The reaction conditions are the same as in Example 1, except that the ratio of the diameter of the reactor inner sleeve to the outer sleeve is 0.62, and the height of the inner sleeve is 5 times the diameter of the outer sleeve. The inner pipe diameter of the mixing nozzle is 15mm, and the ratio of the inner pipe diameter to the outer pipe diameter is 0.5, and the linear velocity of the cyclohexanone oxime organic solution from the inner pipe of the mixing nozzle is 18.0m / s, and the amidation liquid passes through the inner pipe of the mixing nozzle and The linear velocity of the annulus between the outer tubes is 2.9 m / s. The upper part of the reactor is equipped with an enlarged head section for the separation of gas-liquid two-phase, the ratio of the diameter of the enlarged head section to the diameter of the outer sleeve is 3:1

[0057] The reaction results are as follows: the conversion rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com