Rosin-based imidazoline quaternary ammonium salt compound and preparation method thereof

A technology of quaternary ammonium salt compound and rosin-based imidazoline, which is applied in the field of rosin-based imidazoline quaternary ammonium salt compound and its preparation, can solve problems such as unsolved molecular design, achieve superior corrosion inhibition performance, improve purity, and enhance adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

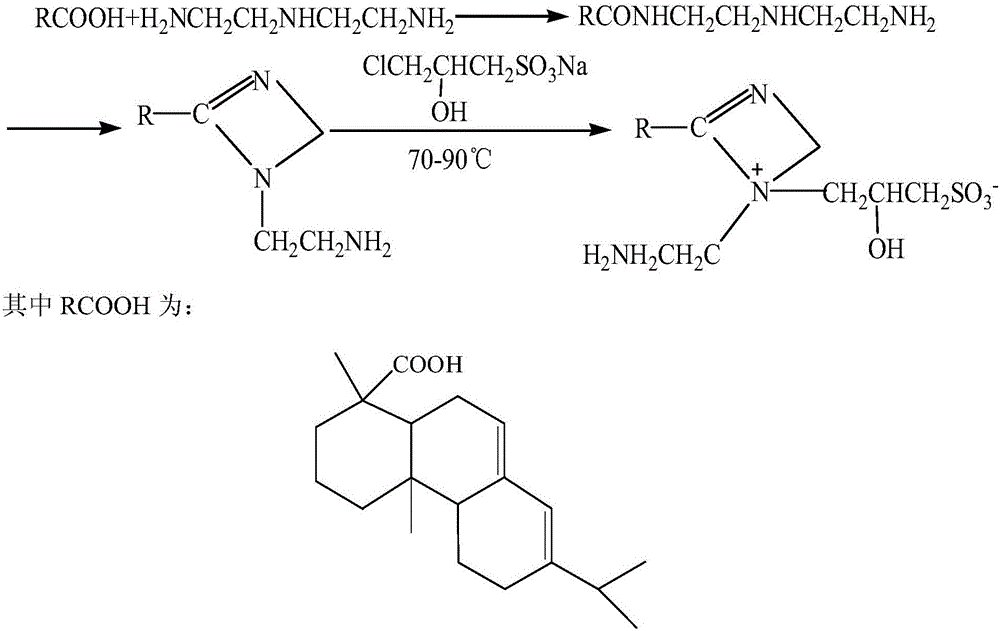

[0032] see figure 1 , the preparation method of rosin-based imidazoline quaternary ammonium salt compound of the present invention comprises the following steps:

[0033] 1) Under nitrogen protection, rosin, diethylenetriamine, water-carrying agent and catalyzer are joined in the reactor that has condensing pipe, stirrer, thermometer, water trap, add magnesium chip or zinc particle simultaneously, and in 150 ℃~160℃ for 4~5 hours. During the reaction process, it can be seen that water is taken out by the solvent. When the water output is basically stable, the temperature is gradually raised to 195℃~205℃ at a heating rate of 1℃ / min. After reacting for 4-6 hours, the water separation volume is basically stable, and the reaction is completed to obtain a rosin imidazoline intermediate; after the obtained rosin imidazoline intermediate is purified with petroleum ether, a purified rosin imidazoline intermediate is obtained;

[0034] Wherein, the substance ratio of rosin and diethyle...

Embodiment 1

[0041] see figure 1 , the preparation of rosin-based imidazoline quaternary ammonium compound, comprising the following steps:

[0042] 1) Add rosin, diethylenetriamine, water-carrying agent, catalyst and magnesium chips to the 2In the four-necked flask of the protective device, dehydrate at 150°C for 4 hours. At this time, water can be seen to be carried out by the solvent, and then gradually increase the temperature to 195°C at a heating rate of 1°C / min, and dehydrate at this temperature 6h, obtain rosin imidazoline intermediate;

[0043] The rosin imidazoline intermediate is distilled off under reduced pressure to remove the unreacted solvent, then washed with petroleum ether and stirred to remove the unreacted rosin, and the purified rosin imidazoline intermediate is obtained;

[0044] Among them, the material ratio of rosin and diethylenetriamine is 1:2, the amount of water-carrying agent added is 20% of the total mass of rosin and diethylenetriamine, and the water-carr...

Embodiment 2

[0048] The preparation of rosin-based imidazoline quaternary ammonium compound comprises the following steps:

[0049] 1) Add rosin, diethylenetriamine, water-carrying agent, catalyst and zinc particles to the 2 In the four-necked flask of the protective device, dehydration was carried out at 160°C for 5 hours. During the reaction, water was gradually seen to be taken out by the solvent, and the water output was basically stable after 5 hours of reaction, and then the temperature was gradually raised to 205 ° C, and dehydration at this temperature for 4 hours, the volume of the separated water is basically stable, and the rosin imidazoline intermediate is obtained;

[0050] The rosin imidazoline intermediate is distilled off under reduced pressure to remove the unreacted solvent, then washed with petroleum ether and stirred to remove the unreacted rosin, and the purified rosin imidazoline intermediate is obtained;

[0051] Among them, the material ratio of rosin and diethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com